Ever wondered what’s happening above your head when snow piles up on your roof or when strong winds blow across your home? It’s all about roof load distribution – the invisible but critical process that keeps your home standing strong through every season.

Roof load distribution is how weight and forces travel from your rooftop through your entire home’s structure down to its foundation. Think of it as your home’s weight management system – when it works properly, everything stays balanced and secure for decades. When it fails, the consequences can range from annoying (like ceiling cracks) to dangerous (structural collapse).

The safety of your family and the longevity of your biggest investment depend on proper roof load distribution. This isn’t just engineer-speak – it’s the fundamental principle behind every well-designed building, from cozy bungalows to sprawling commercial structures.

Most homeowners don’t think about their roof’s structural design until something goes wrong. But understanding the basics can help you make smarter decisions about maintenance, renovations, and even your next roofing material.

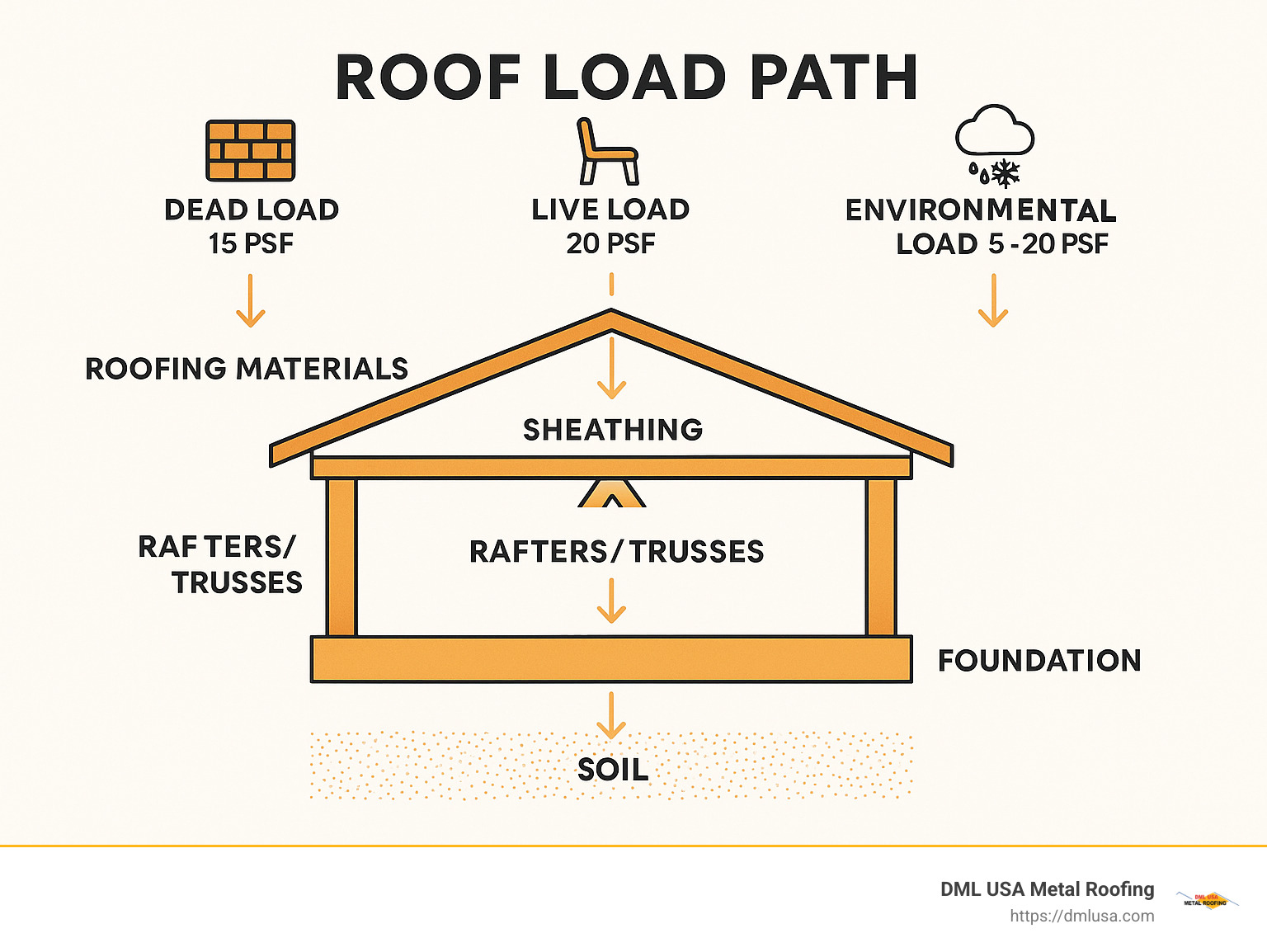

Let’s break down what’s happening up there. Your roof constantly handles three main types of loads: dead loads (the permanent weight of your roofing materials and framing), live loads (temporary weights like snow or workers during maintenance), and environmental loads (forces from wind, rain, or seismic activity). These forces don’t just sit on top of your house – they travel through it in a specific path:

First, your roofing materials transfer weight to the sheathing beneath them. This sheathing then spreads the load to your rafters or trusses, which carry it to your exterior walls or support beams. From there, the weight continues down through your walls to your foundation, which ultimately distributes everything into the soil below.

When this system works in harmony, your home remains stable despite whatever Mother Nature throws at it. When something interrupts this path, trouble follows.

| Load Type | Description | Typical Weight |

|---|---|---|

| Dead Load | Permanent weight (roofing materials, framing) | 10-20 psf |

| Live Load | Temporary weight (snow, maintenance workers) | 20-40 psf |

| Environmental | Wind, rain, seismic forces | Varies by region |

Most homes in the U.S. are designed with roofs that can handle at least 20 pounds per square foot of live load, plus the dead load of the materials themselves. But regional building codes vary based on local conditions – homes in snowy Minnesota need stronger roofs than those in mild California.

I like to explain roof load distribution using a team lifting analogy: When everyone shares the weight evenly, nobody gets hurt. But if one person bears too much, injuries happen. Your roof operates on the same principle – distributed weight keeps everything safe, while concentrated loads cause damage.

Throughout this guide, we’ll explore how different roof designs, materials, and environmental factors affect your home’s structural integrity. We’ll also share practical tips to help you spot potential problems before they become expensive repairs. Whether you’re building new, renovating, or just wanting to understand your home better, you’re in the right place.

Why Roof Load Distribution Is Critical

Ever wonder what keeps your home standing strong through decades of snow, wind, and rain? It’s not luck – it’s proper roof load distribution. This isn’t just some technical concept that engineers obsess over. It’s the silent guardian of your home, your family, and your investment.

Structural Integrity

Think of your home’s structure like a team lifting a heavy object. When everyone shares the weight evenly, the job gets done safely. But if one person bears too much weight? Something’s bound to give.

That’s exactly how roof load distribution works. When designed correctly, your roof system spreads weight across all supporting elements – rafters, trusses, beams, and walls – so no single component takes on more than it can handle.

As one structural engineer colorfully put it, “Wood is not unobtanium. It is a twisting, shrinking, bending, sagging, expanding material.” This simple truth highlights why balanced load distribution matters so much. Building materials have natural limitations, and exceeding those limits through poor load distribution is asking for trouble.

Risk Mitigation

The numbers don’t lie. Insurance companies report that roof-related structural failures rank among their most expensive claims, especially in areas that see severe weather. A revealing study of building collapses during heavy snow events found that poor roof load distribution contributed to over 60% of failures (see the open-access research article on snow-induced building collapses for technical details).

Those aren’t just statistics – they represent real homes, real businesses, and real lives disrupted when roofs fail to perform as they should.

Cost Efficiency

Here’s some good news for your wallet: when a roof distributes loads efficiently, it often requires less building material overall. This means savings during construction and renovations. Plus, a well-designed roof with proper load paths typically needs fewer repairs over its lifetime, potentially saving you thousands in maintenance costs.

Longevity

It’s simple math – buildings with optimal roof load distribution last longer. When forces are spread evenly across your roof system, no single component wears out prematurely. This balanced approach can add decades to your roof’s lifespan. At DML USA, our metal roofing systems are engineered with this principle at heart, distributing loads efficiently while minimizing stress points.

Code Compliance

Building codes aren’t just bureaucratic red tape – they’re there to keep you safe. The International Building Code (IBC) and ASCE 7 (Minimum Design Loads for Buildings and Other Structures) provide specific guidelines for roof load distribution that vary by location. Following these standards isn’t just about checking boxes – it’s about ensuring your home stands strong for generations.

Sustainability & Resilience

As Midwest weather patterns become more unpredictable, a roof that properly distributes loads becomes even more valuable. Well-designed roofs handle extreme weather events better, from heavy snow to high winds. This resilience factor matters more every year, especially here in Illinois where we see everything from summer storms to winter blizzards.

What “Roof Load Distribution” Really Means

Let’s break down what roof load distribution actually means in everyday terms. Imagine your roof during a heavy snowfall. That snow creates weight (load) that needs to travel safely through your home to the ground.

This journey involves several key concepts:

Load Transfer

This is the handoff process. Snow load transfers first to your roofing material, then to the sheathing underneath, then to rafters or trusses, continuing down through walls, and finally to your foundation and the soil below. Each handoff must be clean and efficient.

Stress Flow

Engineers can actually map how forces move through your home, identifying where pressure concentrates. Good design ensures this flow is smooth, avoiding “stress hotspots” that could lead to failure.

Balance & Equilibrium

A properly designed roof achieves perfect balance between all forces – both vertical (like gravity) and horizontal (like wind). When this balance exists, your structure remains stable and secure.

Redundancy

Smart roof designs include backup plans – if one support element fails, others can take over. This safety net approach is crucial for long-term protection.

Roof Load Distribution & Building Failure Statistics

The numbers tell a sobering story about what happens when roof load distribution goes wrong:

- Insurance data shows roof collapses account for roughly 30% of catastrophic building failures.

- In snowy regions, improper load distribution contributes to up to 70% of winter building failures.

- Buildings with flat roofs experience 40% more load-related failures than pitched roofs, primarily because snow and water can accumulate rather than slide off (see the overview of structural load on Wikipedia for background).

This isn’t just theoretical. A few years back in Springfield, Illinois, an older commercial building collapsed during heavy snowfall. The investigation revealed years of water infiltration had weakened critical connection points in the load path. What began as minor maintenance issues eventually led to catastrophic failure.

The lesson? Roof load distribution isn’t just an engineering concept – it’s what keeps disasters like this from happening to your home or business. It’s peace of mind during the next big storm. And with a properly designed metal roof system, it’s one less thing you’ll need to worry about for decades to come.

Types of Roof Loads and How They Interact

When I talk to homeowners about their roofs, I often use the analogy of a backpack. Just like your shoulders feel the weight of everything you carry, your roof shoulders various loads every day. Understanding these loads is key to grasping how roof load distribution works in your home.

Dead Loads

Dead loads are the constant weights your roof carries 24/7, like having a backpack you never take off. These include your roofing materials, structural supports, and anything permanently attached to your roof.

A typical asphalt shingle roof weighs about 2-3 pounds per square foot, while our metal roofing systems at DML USA typically weigh just 1-3 pounds per square foot – one reason they’re so popular for both new construction and retrofits. Add in your plywood or OSB sheathing (about 2 pounds per square foot), your rafters, trusses, ceiling materials, and any permanently mounted equipment like HVAC units or solar panels, and most homes have a dead load between 10-20 pounds per square foot.

Think of dead loads as the reliable friends of your roof – they’re always there, and their behavior is predictable.

Live Loads

Live loads, on the other hand, are the temporary visitors to your roof – sometimes expected, sometimes not. These include the weight of the roofing crew during installation or repairs, furniture on a roof deck, temporarily stored items, and most significantly in Illinois – snow and rain.

Most residential roofs in our region are designed to handle a minimum live load of 20 pounds per square foot, though this varies based on your local building codes. When we design metal roofing systems at DML USA, we’re always thinking about these variable loads and how they interact with the permanent dead loads.

Environmental Loads

Mother Nature doesn’t just send weight downward – she pushes and pulls from all directions. Environmental loads are among the most complex aspects of roof load distribution.

Wind Loads

Wind is a tricky force because it doesn’t just push against your roof – it can actually try to lift it off! This uplift effect happens because wind creates negative pressure (suction) as it flows over your roof, similar to how airplane wings generate lift.

Here in Illinois, our designs typically account for wind speeds of 90-115 mph, creating pressures of about 15-25 pounds per square foot. During severe storms, these forces can be substantially higher. Our metal roofing systems feature specialized fastening patterns specifically designed to resist these lifting forces.

Snow Loads

If you’ve lived through an Illinois winter, you know snow isn’t just beautiful – it’s heavy. Snow loads typically add 20-40 pounds per square foot to your roof’s burden, with design loads in Chicago and northern Illinois generally ranging from 25-30 pounds per square foot.

What makes snow particularly challenging is its uneven distribution. Wind creates drifts that pile snow much deeper in some areas than others, creating concentrated loads that can stress specific parts of your roof structure.

Seismic Loads

While we don’t experience many earthquakes in Illinois, building codes still require consideration of seismic forces. During an earthquake, your roof experiences the most dramatic movement because it’s furthest from the ground – like how the top of a swaying tree moves more than the trunk.

Rain & Ponding Loads

A properly designed roof should shed water quickly, but when drainage is compromised, ponding can occur. Each inch of standing water adds about 5.2 pounds per square foot – a substantial weight that can accumulate quickly. This is why proper drainage design is critical, especially for flatter roof styles.

Dynamic Loads

Some loads come with movement or impact – like vibrations from rooftop equipment, the impact of hail or falling tree limbs, or people walking on accessible roof areas. These dynamic loads can be particularly damaging because they create stress concentrations and fatigue over time.

Load Combinations

In the real world, your roof rarely experiences just one type of load at a time. That heavy snowfall might come with strong winds, while your roof is already carrying its dead load. Building codes specify combinations that must be considered during design, with safety factors built in to account for worst-case scenarios.

Converting Area Loads to Line Loads

Here’s where the engineering rubber meets the road. When designing a roof, we need to translate area loads (measured in pounds per square foot, or psf) into line loads (measured in pounds per linear foot, or plf) to properly size beams, rafters, and trusses.

The math is straightforward: multiply the area load by the “tributary width” – the area that contributes load to a particular structural member. For example, if your rafters are spaced 24 inches (2 feet) apart and your total roof load is 40 psf, each rafter carries 80 plf (40 psf × 2 ft = 80 plf).

This conversion is crucial for ensuring proper roof load distribution throughout your home’s structure.

Environmental Load Nuances

Environmental loads deserve special attention because they behave in complex ways:

Snow Drift

Snow isn’t polite enough to distribute itself evenly across your roof. Wind pushes it into drifts, particularly at roof transitions, behind parapets, and against walls. These drifts can create loads several times higher than the base snow load – a 20 psf base snow load might create 60 psf or more in drift areas.

Wind Uplift

The strongest wind forces typically occur at roof edges, corners, and ridges – places where the airflow separates and creates strong suction. This is why these areas require special attention during installation, with additional fasteners and reinforcement. Our metal roofing systems are engineered with these forces in mind, with specific fastening patterns for different roof zones.

Seismic Acceleration

During an earthquake, the ground moves horizontally as well as vertically. Your roof, being at the top of the building, experiences the greatest amplification of these movements. That’s why roof-to-wall connections are critical in seismic design – they’re the links in the chain that keep everything together when the earth moves.

Regional Maps & Safety Factors

Building codes don’t just guess at these forces – they provide detailed maps based on historical data for snow, wind, and seismic loads across different regions. Engineers then apply safety factors to account for uncertainties and ensure protection against extreme events.

At DML USA, we’re passionate about designing metal roofing systems that handle all these forces beautifully while providing the longevity and peace of mind that comes with proper roof load distribution. After all, understanding the weight above your head is the first step toward ensuring it stays where it belongs – safely supported by your home’s structure.

The Load Path: From Roof Deck to Foundation

Ever wonder how the weight of heavy snow on your roof safely travels all the way down to the ground without crushing everything in between? That’s the magic of a properly designed load path – the invisible highway that guides forces through your home’s structure.

Think of your home as a team relay race, where the baton (weight) gets passed from runner to runner (structural component to structural component) until it crosses the finish line (reaches the soil). If any runner drops the baton, the whole race falls apart – just like your home would if the load path is interrupted.

The Complete Path

When a snowflake lands on your roof, it begins a journey through your home that looks something like this:

First, your roofing materials catch that snowflake and its thousands of friends. This weight pushes down on the sheathing – typically plywood or OSB panels that form the roof deck. The sheathing then distributes this weight to the rafters or trusses running underneath.

These rafters or trusses – the skeleton of your roof – carry the load to either a ridge beam at the peak or to your exterior walls (often both). From there, the load continues downward through wall studs or columns, which transfer everything to your foundation. Finally, your foundation spreads all this weight across the soil beneath your home.

As structural engineer John Carroll explains: “The dead loads on most roofs are pretty small; because the roof is the highest part of the frame, it merely has to carry its own weight and the weight of the shingles. If you’re building in an area where heavy snow, high winds, or seismic events occur, the roof structure has to be designed and detailed to meet those conditions.”

Key Components in the Load Path

Your roof’s load path relies on several crucial players working together:

Rafters & Trusses form the primary framework supporting your roof. Traditional rafters are individual boards that slope from ridge to wall, while trusses are pre-engineered triangular frameworks spanning from wall to wall. How close together these members are placed (typically 16, 19.2, or 24 inches apart) determines how much weight each one needs to handle.

Purlins are horizontal supports that span between rafters or trusses in many roofing systems, especially metal ones. They create attachment points for metal panels while helping distribute loads more evenly across the structure. At DML USA, we carefully calculate purlin spacing based on the specific metal panels being installed and the expected loads they’ll face.

Beams are larger structural members that support groups of rafters, trusses, or purlins. The ridge beam at your roof’s peak is particularly important, as it supports the upper ends of rafters in many designs.

Load-Bearing Walls transfer roof weight downward. Not all walls in your home serve this purpose – identifying which ones do is crucial when planning renovations.

Columns are vertical supports that help carry concentrated loads from beams down to the foundation.

Footings form the bottom of your foundation system, spreading concentrated loads over a wider soil area to prevent settlement.

Connections might be the most critical elements of all – the fasteners, hangers, ties, and straps that join all these components together. A roof system is only as strong as its weakest connection.

Gravity vs Lateral Load Paths

While gravity pulls everything straight down, creating a relatively straightforward load path, nature throws other forces at your roof that follow more complex routes.

Vertical Forces from gravity create compression in walls and columns while causing bending in horizontal elements like rafters and beams. These are the forces most homeowners intuitively understand.

Horizontal Forces from wind and earthquakes push sideways against your home, requiring specialized systems to redirect them safely to the ground:

Your roof sheathing acts as a diaphragm that collects lateral forces and distributes them to the walls below. Shear walls – specially reinforced wall sections – resist these sideways forces and transfer them to the foundation. Meanwhile, uplift straps and ties connect roof elements to walls and walls to foundations, creating a continuous path for both downward and upward forces.

Without these lateral systems, your home would sway dangerously in high winds or during seismic activity.

Common Mistakes in Load Paths

Even well-built homes can have load path problems. Here are the issues we most commonly see:

Interrupted Framing happens when structural elements aren’t properly aligned or when someone cuts into them for plumbing or HVAC without appropriate reinforcement. This creates gaps in the load path where forces can concentrate.

Undersized Connectors are particularly common in DIY renovations. Those little metal joist hangers and hurricane ties may seem insignificant, but they’re engineered to transfer specific loads. Using the wrong size or type creates weak links in your load chain.

Mixed Materials expand, contract, and flex differently under load. The interfaces between wood, steel, and concrete require special attention to ensure proper load transfer across these material boundaries.

Lack of Redundancy is a silent danger. Well-designed structures include multiple load paths so if one fails, others can compensate. Buildings lacking this redundancy are more vulnerable to progressive collapse – where one failure triggers a cascade of structural failures.

“A proper load path ensures safe, efficient transfer of weight, prevents overloading of any component, maintains structural integrity, and avoids safety hazards or costly repairs,” notes a structural design guide. This perfectly captures why understanding roof load distribution is so crucial for every homeowner.

The beauty of metal roofing systems like those we design at DML USA is how they’re engineered from the start to create efficient, reliable load paths with fewer components and connection points – reducing the potential for these common mistakes while providing superior protection against the elements.

Roof Designs & Materials: Impact on Roof Load Distribution

The shape of your roof and what it’s made from aren’t just about curb appeal—they fundamentally change how weight gets distributed throughout your home. Think of your roof design as a weight-lifting strategy, with each style having its own approach to handling the burden above your head.

Common Roof Designs

Flat Roofs

Despite the name, flat roofs typically have a slight slope (about 1/4 inch per foot) for drainage. While popular for modern homes and commercial buildings, these roofs come with unique considerations.

Flat roofs typically support less weight than their pitched cousins, usually handling between 20–30 psf. They’re more vulnerable to snow buildup and water pooling, which can create dangerous concentrated loads. The weight on a flat roof travels primarily through horizontal beams and joists to the walls around the perimeter.

I’ve seen too many flat roofs fail because owners forgot the golden rule: regular maintenance is non-negotiable. Without proper drainage care, even a well-designed flat roof can develop problems.

Gable Roofs

The classic triangular roof we all drew as children handles loads quite differently than flat designs. These familiar pitched roofs typically manage 20-40 psf live loads with relative ease.

One of the gable roof’s superpowers is shedding snow and rain naturally, thanks to gravity’s helping hand. The weight travels through rafters or trusses until it reaches the exterior walls. One thing many homeowners don’t realize is that gable roofs create horizontal pushing forces at the walls that must be counteracted with proper structural design.

Hip Roofs

With slopes on all four sides, hip roofs handle similar loads to gable designs (20-40 psf) but distribute them differently. Their design creates superior wind resistance—something our customers in windier parts of Illinois particularly appreciate.

The load path is more complex, flowing through hip rafters and jack rafters in a pattern that ultimately strengthens the entire structure. As one structural design guide notes, “Hip roofs have demonstrated better performance than gable-end roofs in hurricanes,” which explains their popularity in storm-prone regions.

Mansard Roofs

These distinctive French-inspired roofs with two slopes on all four sides create dramatic curb appeal while handling 20-40 psf live loads. Their complex design means weight follows a more intricate path through multiple framing members.

Mansard roofs often incorporate beautiful dormer windows, but these create potential weak points in the load path if not properly designed. The transition between the steeper lower slope and gentler upper slope requires careful waterproofing attention—something we always emphasize during installation.

A-frame Roofs

These steep, dramatic roofs that form both the walls and roof in one structure are load-distribution powerhouses. Their higher load capacity (30-40 psf) comes from their steep pitch, which excels at shedding snow before it can accumulate to dangerous levels.

A-frames transfer weight directly through the roof/wall structure to the foundation with remarkable efficiency. The trade-off? You’ll sacrifice some interior space at the edges due to those dramatic sloping walls.

Concrete Slab Roofs

Common in commercial construction, concrete slab roofs are the heavyweight champions of roof load distribution. Their impressive load capacity (often exceeding 50 psf) and excellent fire resistance make them ideal for certain applications.

These substantial roofs distribute loads through reinforced concrete to columns or walls, but their significant dead weight requires stronger supporting structures throughout the building. They’re rarely seen in residential construction except in certain modern architectural styles.

Roofing Materials

What your roof is made from dramatically affects both its permanent weight (dead load) and how it handles environmental forces like snow and wind.

Metal Roofing

As specialists in metal roofing at DML USA, we’re particularly fond of this material’s advantages for roof load distribution. Metal roofing is remarkably lightweight (just 1-3 psf), which reduces the permanent burden on your home’s structure. This lighter dead load means the entire building experiences less stress day in and day out.

On sloped applications, metal’s smooth surface excels at shedding snow before it can build up to dangerous levels. With proper installation techniques, metal roofing provides superior wind resistance—a critical factor during Illinois’ sometimes turbulent weather.

Perhaps most impressive is metal roofing’s longevity—50+ years with minimal maintenance isn’t just good for your wallet, it’s good for the planet too. Many of our customers also appreciate the energy efficiency benefits, which can potentially qualify for tax credits.

Asphalt Shingles

America’s most common residential roofing material sits in the middle of the weight spectrum at a moderate 2-3 psf. Most asphalt roofs are designed for 20-25 years of service, though actual lifespan varies widely based on installation quality and local climate conditions.

Asphalt offers moderate wind resistance (up to 110 mph with improved installation methods), but one downside is thermal performance—these dark materials absorb and retain heat, potentially increasing your summer cooling costs.

Clay or Concrete Tiles

Popular in Mediterranean and Spanish-style homes, these beautiful tiles come with significant weight considerations. At 10-20 psf, they’re among the heaviest roofing options and require robust structural support.

The trade-off for this weight is exceptional durability—50+ years is common with proper installation and maintenance. Their thermal mass provides excellent insulating properties, but here’s a critical note: if you’re replacing a lighter roof with tile, you’ll likely need additional structural reinforcement. I’ve seen too many homeowners skip this step and regret it later.

Wood Shingles/Shakes

These traditional materials offer a distinctive, natural appearance that many homeowners love. At a moderate 3-4 psf, they won’t overburden most structures designed for standard loads.

Wood roofing provides natural insulating properties that synthetic materials can’t match. The downside? They demand regular maintenance to prevent moisture issues and present higher fire risks unless properly treated. In some municipalities, building codes restrict their use entirely.

Slate

The premium choice for generations, natural slate offers best elegance and extreme longevity—potentially 100+ years. This exceptional durability comes with substantial weight (8-15 psf) that requires significant structural support.

Slate’s fire resistance is excellent, but installation must be performed by specialists with specific expertise. The investment pays dividends in longevity and curb appeal, but your structure must be designed or reinforced to handle the considerable weight.

How Pitch Changes Load Flow

The steepness of your roof dramatically affects how roof load distribution works:

Slope Factor

As your roof gets steeper, physics works in your favor regarding snow loads. Building codes recognize this with slope factors that reduce design snow loads for steeper roofs. For example, a roof with a 12:12 pitch (45 degrees) might only need to handle 70% of the ground snow load, while a 4:12 pitch might require the full 100%.

This isn’t just theoretical—it translates to real savings in construction costs since steeper roofs can often use lighter structural members.

Runoff Efficiency

Water is a roof’s natural enemy, and steeper roofs shed it more efficiently. This reduces the risk of leaks and water damage, particularly in high-rainfall areas. I’ve seen countless problems in low-pitch roofs that would never have occurred with a steeper design.

Snow Shedding

Steeper roofs naturally shed snow before it can accumulate to dangerous levels, reducing the duration of snow loads on the structure. However, this creates a new consideration—where will all that snow go? Without proper planning, you might create safety hazards below or damage to landscaping and adjacent structures.

Uplift Sensitivity

Roof pitch significantly changes how wind interacts with your home. Steeper roofs generally experience different pressure patterns than flatter ones. While they may reduce uplift on the main roof surface, they can create higher suction forces near ridges and edges—areas that require special attention during installation.

Metal Roofs & Load Efficiency

At DML USA Metal Roofing, we’ve spent years perfecting metal roofing systems that optimize roof load distribution while providing outstanding long-term performance.

Lightweight Steel

Our metal roofing panels weigh significantly less than traditional materials, creating several structural advantages. This reduced dead load means less constant stress on your home’s structure, potentially allowing for lighter supporting members and reduced foundation requirements in new construction.

Over decades, this lighter weight reduces the cumulative stress on your home’s structure, potentially extending its serviceable life.

Purlin Spacing & Design

Metal roofing systems rely on purlins—horizontal structural members that support the panels and distribute loads to the main structural elements. Getting the purlin spacing right is critical for optimal load distribution.

Depending on your specific load requirements, we might recommend Z-shaped (Zee-purlins) or C-shaped (Cee-purlins) supports. As one metal roofing guide explains, “Zee-purlins are ideal for heavy-load areas, whereas Cee-purlins offer more versatility and ease of installation.” Our design team evaluates each project’s unique needs to recommend the optimal configuration.

Energy Credits & Performance

Beyond the structural benefits, our metal roofing systems deliver additional advantages that homeowners appreciate:

The reflective surfaces significantly reduce heat absorption, keeping your home cooler in summer. Many of our products qualify for energy tax credits, putting money back in your pocket while reducing your environmental impact. The long-term durability—with minimal maintenance requirements—makes metal roofing an excellent investment for decades of worry-free performance.

“Metal recover overlays can extend roof life beyond 50 years without full tear-off,” notes a roofing industry report. This exceptional longevity makes metal roofing a wise investment for long-term roof load distribution performance.

Calculating Roof Load Step-by-Step

Accurate calculation of roof loads is essential for proper roof load distribution. While professional engineers should handle complex calculations, understanding the basic process helps homeowners and builders make informed decisions.

Step 1: Identify All Applicable Loads

Begin by listing all loads that will affect your roof:

- Dead loads: Weight of roofing materials, sheathing, structural members, ceilings, and permanently attached equipment

- Live loads: Maintenance personnel, temporary storage

- Environmental loads: Snow, wind, rain, seismic forces

Step 2: Sum Dead & Live Loads

Calculate the total dead load by adding the weights of all permanent components:

For example:

- Metal roofing: 1.5 psf

- Sheathing (1/2″ OSB): 1.5 psf

- Rafters/trusses (average): 2.5 psf

- Ceiling: 2.0 psf

- Insulation: 1.0 psf

- Miscellaneous: 1.5 psf

- Total dead load: 10.0 psf

Add the required live load (typically 20 psf for residential roofs):

- Combined dead and live load: 30 psf

Step 3: Add Environmental Loads

Determine environmental loads based on your location and building codes:

- Snow load: Consult local building code (e.g., 25 psf for Chicago)

- Wind load: Calculate based on design wind speed, exposure category, and roof geometry

- Rain load: Consider for low-slope roofs with potential for ponding

Step 4: Convert to Pounds Per Square Foot (PSF)

Express all loads in consistent units (typically psf) for easy comparison and combination.

Step 5: Apply Slope Factors

For pitched roofs, apply slope factors to adjust snow loads:

- Roofs steeper than 70° generally don’t need to account for snow accumulation

- Roofs between 30° and 70° use a sliding scale of reduction

- Roofs less than 30° typically use the full design snow load

Step 6: Convert to Pounds Per Linear Foot (PLF)

Convert area loads (psf) to line loads (plf) for structural member design:

Line Load (plf) = Area Load (psf) × Tributary Width (ft)

For example, if rafters are spaced 24″ (2 ft) apart and the total roof load is 55 psf:

- Line load on each rafter = 55 psf × 2 ft = 110 plf

Step 7: Size Beams/Trusses/Rafters

Use the calculated loads to determine appropriate sizes for structural members:

- Consult span tables in building codes

- Consider deflection limits (typically L/240 or L/360)

- Account for wood species and grade when using lumber

Step 8: Check Deflection Limits

Ensure that the selected members won’t bend excessively under load:

Maximum Deflection = Span (inches) ÷ Deflection Factor

For example, for a 120″ span with an L/360 deflection limit:

- Maximum allowable deflection = 120″ ÷ 360 = 0.33″

Sample Calculation Walkthrough

Let’s work through a complete example for a 1,500 sq ft residential roof in Chicago:

Step 1: Identify Loads

- Dead load: Metal roofing system (10 psf)

- Live load: Standard residential (20 psf)

- Snow load: Chicago design load (25 psf)

- Wind load: Calculated as 15 psf

Step 2 & 3: Sum All Loads

- Total load to consider: 10 + 20 + 25 = 55 psf

(Wind load is not added directly but considered separately for uplift and lateral forces)

Step 4: Convert to PSF

- All loads are already in psf

Step 5: Apply Slope Factors

- Assuming a 6:12 pitch (26.6°), snow load is reduced to approximately 22 psf

- Adjusted total load: 10 + 20 + 22 = 52 psf

Step 6: Convert to PLF

- Assuming rafters at 24″ o.c.: 52 psf × 2 ft = 104 plf

Step 7: Size Rafters

- For a 12′ span with 104 plf load

- Consulting span tables: 2×10 rafters (SPF #2) would be adequate

Step 8: Check Deflection

- Span = 12′ = 144″

- Deflection limit L/240: 144″ ÷ 240 = 0.6″

- 2×10 SPF #2 deflection under this load and span is approximately 0.55″ (acceptable)

Total Load on Entire Roof

- 1,500 sq ft × 52 psf = 78,000 lbs total load

This calculation demonstrates the substantial forces at work in even a modestly sized residential roof, highlighting the importance of proper roof load distribution.

Digital & AI Tools That Simplify the Math

Modern technology has made roof load calculations more accessible and accurate:

Specialized Software

Professional-grade structural analysis software like ClearCalcs and Autodesk’s structural suite can:

- Automatically calculate complex load combinations

- Model entire roof systems in 3D

- Track load paths through the structure

- Generate detailed reports for permitting

“Using dynamic load-path tracking software can automatically update loads across all members when parameters change,” notes a structural engineering resource.

Spreadsheet Templates

Many engineers and builders use custom spreadsheets that:

- Incorporate local code requirements

- Calculate tributary areas automatically

- Apply appropriate safety factors

- Generate material specifications

Mobile Apps

Several mobile applications now offer simplified roof load calculators that:

- Access local code data based on GPS location

- Allow input of basic roof dimensions and materials

- Provide preliminary estimates for common configurations

- Help identify potential problem areas

Emerging AI Tools

Artificial intelligence is beginning to transform structural analysis:

- Machine learning algorithms can predict snow accumulation patterns

- Computer vision can analyze existing structures from photographs

- Predictive modeling can simulate decades of load cycles in seconds

“AI integration in structural design will lead to smarter, more energy-efficient buildings,” predicts a construction technology expert.

These digital tools don’t replace professional engineering judgment but can significantly improve accuracy and efficiency in designing for proper roof load distribution.

Avoiding Errors, Meeting Codes & Spotting Trouble

Let’s face it—even with the best intentions, things can go wrong with roof load distribution. But knowing what to watch for can save you from costly mistakes and potential dangers. I’ve seen my fair share of roofing mishaps over the years, and most could have been prevented with a little knowledge.

Common Calculation Errors

We all make mistakes, but when it comes to calculating roof loads, errors can have serious consequences.

Underestimating loads is probably the most common mistake I see. It’s easy to forget about that heavy HVAC unit or not account for all the layers in your roofing system. I remember a homeowner in Springfield who used an online calculator but completely overlooked their rooftop air conditioning unit. When a professional reassessed the situation, they found the loads were dangerously underestimated.

Many homeowners also don’t think about future changes. That beautiful metal roof might easily support today’s loads, but what about when you add solar panels next year? Or convert part of the attic to living space? Planning for these future additions can save you significant headaches down the road.

Span tables in building codes are another tricky area. These tables tell you how far a structural member can safely span, but they come with important footnotes and conditions. Using the wrong table for your specific wood species or misunderstanding wet service conditions can lead to undersized structural members that won’t adequately handle your roof load distribution.

Perhaps most overlooked are the connections between structural elements. You can have perfectly sized rafters and trusses, but if the hardware connecting them is inadequate, you’ve still got a problem. It’s like having strong chain links connected by paperclips—the system is only as strong as its weakest point.

Building Code Requirements

Building codes aren’t just bureaucratic red tape—they’re life-saving standards developed from decades of research and sometimes, unfortunately, from building failures.

The International Building Code (IBC) serves as the foundation for most local building codes. It covers everything from minimum design loads to material specifications. Think of it as the collective wisdom of thousands of building experts packed into one (admittedly dense) document.

ASCE 7 (that’s the American Society of Civil Engineers’ standard #7) goes even deeper into load requirements. It provides those detailed maps showing how much snow or wind your region typically experiences, and how to translate those environmental forces into structural design requirements.

What makes things interesting is that most jurisdictions add their own local amendments to these national codes. A roof in snowy Chicago needs different roof load distribution than one in sunny Phoenix. As a building code expert once told me, “Local building codes set minimum standards for safety based on regional conditions and ensure legal compliance.” This is why local knowledge is so valuable when designing roof systems.

The permitting process, while sometimes frustrating, serves as a crucial safety check. Plan reviews and inspections catch errors before they become problems, and the documentation becomes valuable if you ever sell your home or need to make future changes.

Visual Signs Your Roof Is Overloaded

Your roof will often tell you when it’s struggling—if you know what to look for.

A sagging ridge line is perhaps the most obvious sign. Stand at the end of your house and look at the roof line—it should be straight as an arrow. Any noticeable dip could indicate that your roof load distribution isn’t working properly. This could be from undersized rafters, excessive snow loads, or deteriorating wood members.

Inside your home, keep an eye out for cracked drywall or plaster, especially where walls meet ceilings. These cracks often appear when the roof structure is moving more than it should. They might come and go with the seasons as loads change and materials expand and contract.

Have you noticed doors or windows suddenly sticking? When roof loads cause structural movement, it often affects these openings. Frames can become out of square, clearances change, and suddenly that bedroom door that worked perfectly for years needs a good shove to close.

Water stains or leaks can both cause and result from roof load distribution problems. As a structure moves under load, it can compromise flashing or create openings for water to enter. This water then weakens the structure further, creating a dangerous cycle.

Don’t ignore those strange popping or creaking sounds, especially during temperature changes or when snow is accumulating. Your house is talking to you! These noises often indicate wood members adjusting under stress or fasteners working loose—early warning signs that shouldn’t be ignored.

Maintenance Practices That Protect Load Capacity

Taking care of your roof isn’t just about preventing leaks—it’s about maintaining its structural integrity and proper roof load distribution.

Debris removal is more important than many homeowners realize. Those fallen leaves might seem harmless, but when they clog gutters or pile up in valleys, they add weight and prevent proper drainage. After storms, take a few minutes to clear branches and debris. If you have a flat or low-slope roof, consider removing excessive snow accumulation before it exceeds your roof’s design capacity.

Regular fastener checks can prevent small issues from becoming big problems. Metal roofing systems, like those we install at DML USA, rely on properly torqued fasteners to maintain their structural integrity and weather resistance. Over time, thermal cycling can cause fasteners to loosen slightly. A quick inspection and tightening can prevent more serious issues.

When it comes to snow clearing, a little knowledge goes a long way. Use plastic shovels rather than metal ones to avoid damaging your roofing materials. It’s actually better to leave a thin layer of snow than to scrape all the way to the surface. And please, work from the ground using long-handled tools when possible—no roof is worth risking your safety.

Perhaps most valuable is an annual professional inspection. A qualified roofing professional brings trained eyes and experience to spot issues you might miss. They’ll check not just the roofing materials but also flashing, penetrations, and visible structural components. As roofing experts consistently recommend, “Regular roof maintenance and debris removal to maintain load-bearing capacity” is one of the best investments you can make in your home’s longevity.

For more detailed maintenance tips specific to metal roofing, check out our blog posts where we regularly share professional advice drawn from our years of experience in the industry.

Reinforcement Options & Case Studies

When roof load distribution problems show up, you don’t need to panic. There are plenty of ways to strengthen your roof and get it back in fighting shape. Let’s look at some proven solutions and real-life examples that show how these fixes work in the wild.

Common Reinforcement Techniques

Sistering Rafters

One of the simplest and most effective ways to strengthen your roof is by adding support members alongside your existing rafters. This technique, called sistering, gives an immediate boost to your roof’s strength without major disruption to your living space.

“A simple DIY reinforcement by attaching 2x4s to existing trusses can substantially increase load capacity,” according to a building rehabilitation guide I recently read. It’s like giving your roof a helping hand exactly where it needs it most.

What I love about sistering is that you can target just the problem areas, making it a cost-effective solution that doesn’t require tearing apart your entire ceiling. For many homeowners facing localized roof load distribution issues, this is the perfect first step.

Adding Purlins

Purlins are horizontal beams that run across your rafters or trusses, and they’re absolute workhorses when it comes to improving roof load distribution. They effectively shorten the span that each rafter needs to cover, spreading weight more evenly across the structure.

I’ve seen purlins transform sagging roofs into rock-solid structures. They’re particularly useful when you’re planning to install a new metal roof, as they create perfect attachment points for the panels. For longer spans, we often combine purlins with vertical king posts for additional support.

Installing Structural Ridge Beams

If you’ve got a traditional roof with a non-structural ridge board (the board at the peak), upgrading to a load-bearing ridge beam can make a world of difference. This upgrade supports the upper ends of your rafters, taking pressure off your exterior walls.

The beauty of a proper ridge beam is that it can sometimes allow you to remove interior walls, opening up your living space. It’s like getting a structural upgrade and a home improvement project all in one!

Steel Retrofits

When wood just won’t cut it, steel comes to the rescue. Steel reinforcements offer tremendous strength while adding minimal bulk to your existing structure. There are several approaches:

Steel plates bolted to existing wood members provide immediate strength. Flitch plates (steel sandwiched between wood) combine the best properties of both materials. For roofs pushing outward on walls, steel tension rods can pull everything back into alignment. And in critical connection points, steel brackets can create rock-solid joints.

Roof Recover Systems

For commercial buildings with aging metal roofs, specialized recover systems can work wonders. “Metal recover systems typically add less than three pounds per square foot, acceptable under most building codes,” according to industry specifications I’ve reviewed.

These systems can add slope to flat roofs for better drainage, increase insulation for energy savings, fix structural problems, and extend roof life—all without the mess and expense of a complete tear-off. At DML USA, we’ve helped many commercial clients transform problematic roofs into high-performing assets.

Tech-Driven Monitoring & Predictive Maintenance

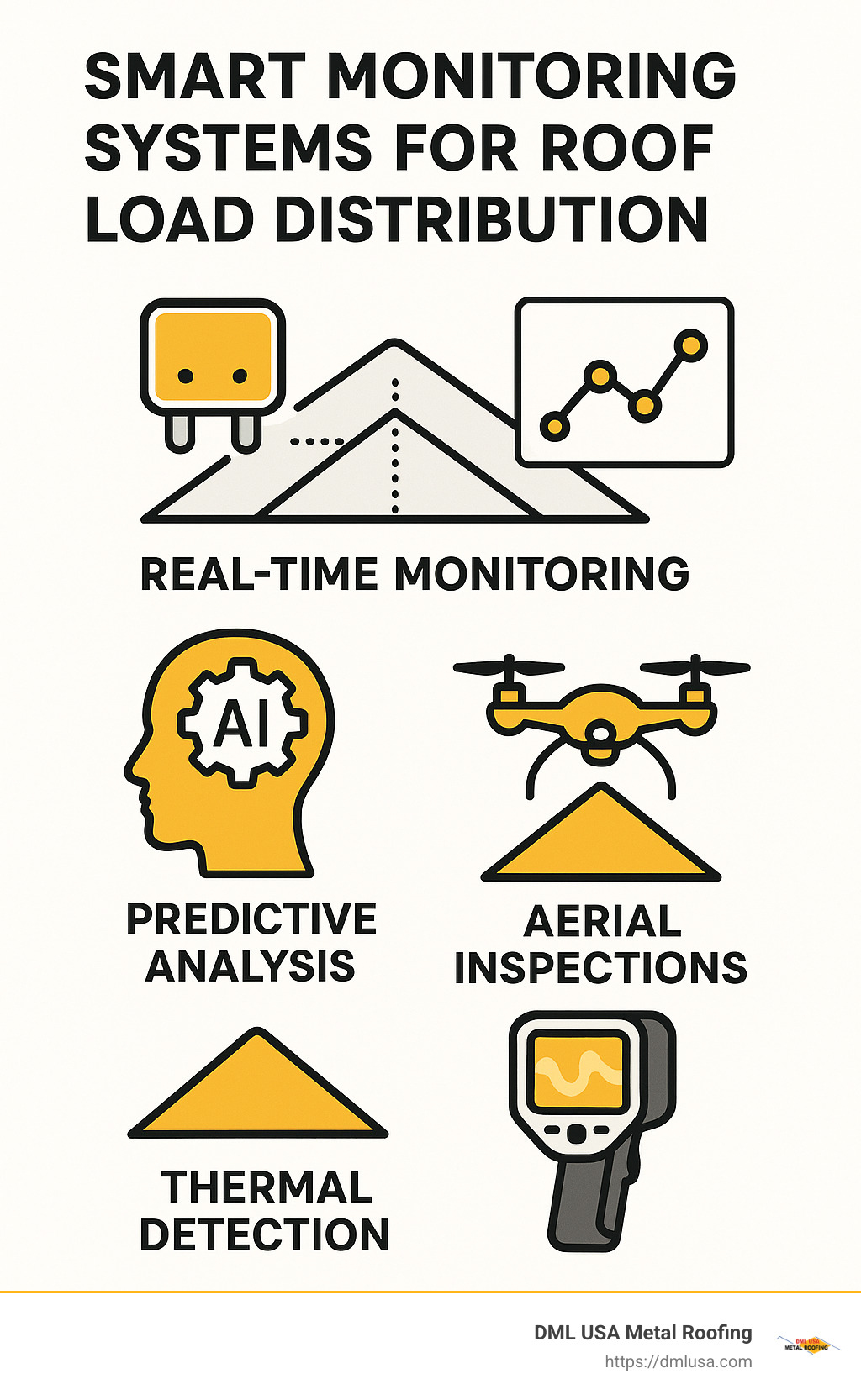

The future of roof load distribution management is here, and it’s smarter than ever. Modern technology gives us new ways to watch over our roofs and catch problems before they become disasters.

IoT Strain Gauges

Imagine tiny sensors placed on critical roof beams that constantly monitor the pressure on your roof. These smart devices can send real-time data to your phone, alerting you when snow loads approach dangerous levels or when something doesn’t look right.

These sensors create a historical record of how your roof handles different conditions, helping engineers make better decisions about reinforcement or replacement. It’s like having a 24/7 structural engineer keeping an eye on things.

AI-Powered Predictive Analytics

Artificial intelligence isn’t just for science fiction anymore. AI systems can analyze data from your roof to predict where problems might develop, recommend maintenance before it’s urgently needed, tell you exactly when snow removal is critical, and spot changes in how your roof handles loads.

This technology is especially valuable for commercial buildings where roof failures can mean business interruptions and significant liability risks.

Drone Inspections

Why climb on your roof when a drone can do the dangerous work? Equipped with high-resolution cameras and sometimes specialized sensors, drones can:

Capture detailed images of your entire roof surface, create 3D models that engineers can analyze from their desks, spot drainage issues that might lead to ponding, and even measure how much your roof is deflecting under load. All this without a single ladder or safety harness!

Thermal Imaging

Infrared cameras reveal what the naked eye can’t see. They detect heat differences that can indicate hidden problems like water seeping into your insulation, heat escaping through poorly insulated areas, the location of structural elements hidden within walls and ceilings, and temperature patterns that might affect how your roof handles loads.

Real-World Project Snapshots

Let me share some stories from our project files that show how roof load distribution solutions work in real life.

Hip Roof Retrofit in Northern Illinois

A family in northern Illinois reached out to us about their 1960s home. Their roof was visibly sagging under winter snow loads, and they were worried about a potential collapse. Upon inspection, we found inadequate collar ties and rafters that were simply too small for the job.

Our solution was a complete DML USA metal roofing system that addressed both the structural issues and their desire for an energy-efficient roof. We installed new structural purlins to better distribute the load across the rafters, added properly positioned collar ties, and topped it all with our snow-shedding metal panels. We also improved the ventilation system to prevent ice dams.

The results were better than anyone expected. Not only does the roof now handle heavy Illinois snow without a hint of sagging, but the homeowners were thrilled to see their heating bills drop significantly thanks to the energy-efficient metal roofing system.

Commercial Flat-to-Slope Conversion

A retail building owner in Chicago was at his wit’s end with an aging flat roof. Despite repeated repairs, leaks kept appearing, and water was ponding in several areas after every rain.

We designed a comprehensive solution using our metal roofing system. First, we installed light-gauge steel framing to create a 3:12 slope. Rather than tearing off the existing membrane (a messy and expensive proposition), we left it in place to serve as a vapor barrier. We added high-performance insulation between the framing members and topped it all with our durable metal panels.

The change was remarkable. The building owner hasn’t had to deal with a single leak since the conversion, his energy costs dropped by 23% (enough to help pay for the roof over time), and he qualified for energy-efficiency tax credits that further offset the investment.

Snow-Belt Cabin Upgrade

A vacation cabin near the Wisconsin border had become a source of anxiety rather than relaxation for its owners. During heavy snow events, they could actually see the roof deflecting under the weight, making them worry about spending the night.

Our team developed a multi-faceted solution. We sister-raftered the entire roof structure for immediate strength, replaced the non-structural ridge board with a proper load-bearing ridge beam, and installed a metal roofing system with specialized snow guards. We also improved the eave details to prevent ice dams, a common problem in the region.

Now the cabin can safely handle snow loads exceeding 40 psf without visible movement. The smooth metal surface allows snow to shed in a controlled manner, and the owners can finally enjoy winter weekends without worrying about what’s happening overhead.

Hurricane-Zone Metal Roof Installation

While Illinois isn’t known for hurricanes, we occasionally work with clients in coastal areas who need roofs that can stand up to extreme winds. One such project involved a beautiful coastal property that needed improved wind resistance without sacrificing its classic look.

We designed a custom-engineered metal roofing system with wind-rated panels and an improved fastening pattern. We paid special attention to the roof perimeter, where wind forces are strongest, with reinforced attachments. Strategic placement of wind guards helps manage airflow across the roof surface, and we integrated a lightning protection system for added security.

The investment has already paid off through multiple high-wind events. The roof has remained intact while neighboring properties suffered damage, and the owners even received reduced insurance premiums due to the improved resilience of their home.

These real-life examples show how thoughtful roof load distribution solutions do more than just fix problems—they can transform buildings, improve energy efficiency, reduce maintenance headaches, and provide decades of worry-free protection.

Frequently Asked Questions about Roof Load Distribution

How do local building codes affect roof load distribution requirements?

When it comes to roof load distribution, your local building codes aren’t just suggestions—they’re critical safeguards custom to your region’s specific challenges.

Here in Illinois, we see this firsthand. Northern Illinois communities like Chicago require higher snow load capacities (typically 25-30 psf) than our southern neighbors. It makes perfect sense when you think about it—a roof in Chicago faces very different winter conditions than one in Carbondale!

These local codes build upon national standards like the International Building Code and ASCE 7, adding region-specific requirements that address everything from minimum beam sizes to exactly how your roof needs to connect to your walls. They also establish the inspection process you’ll need to follow to ensure everything is up to snuff.

I spoke with Mark, a local building inspector, who put it perfectly: “Building codes aren’t about making life difficult—they’re about keeping families safe through standards that have been learned, sometimes the hard way, through decades of experience.”

If you’re planning any roofing project, I strongly recommend:

- Talking to your local building department before you even pick up a hammer

- Working with contractors who know your area’s specific requirements

- Getting all the proper permits and inspections

- Keeping your approval documentation for the future (especially helpful when selling your home)

What tools can homeowners use to estimate roof loads safely?

While nothing replaces professional engineering, there are several helpful tools that can give you a basic understanding of your roof’s roof load distribution before you call in the experts.

Many homeowners I work with start with online calculators that provide ballpark estimates based on your roof’s dimensions, materials, and zip code. These tools can help you understand the difference between dead loads (the permanent weight of your roof) and live loads (temporary weights like snow or workers).

Span tables are another valuable resource. These charts, available in building codes and lumber industry publications, show how far different sizes of wood can safely span under various load conditions. They’re particularly helpful when you’re trying to understand if your existing structure is adequate.

There are also some pretty impressive smartphone apps available now. I recently helped a customer in Peoria who used an app to measure his roof pitch and dimensions just by taking photos from the ground—technology that would have seemed like magic just a decade ago!

That said, I always caution homeowners about the limitations of DIY calculations. I remember working with a family in Springfield who used an online calculator but completely overlooked the weight of their rooftop HVAC unit. This oversight led to a significant underestimation of their actual roof load. The calculator wasn’t wrong—it just didn’t know about that specific detail of their home.

Think of these tools as a starting point for understanding, not as a replacement for professional expertise. They’re great for getting educated, but they can’t account for the unique aspects of your specific home.

When should a professional engineer be consulted?

There are definitely times when DIY approaches work fine, but when it comes to roof load distribution, certain situations absolutely call for professional engineering expertise.

Any new construction should have professional structural design. Period. This ensures your home is built to current codes with properly sized structural elements and a comprehensive analysis of how loads will travel through your home. This isn’t an area to cut corners—proper engineering at the beginning prevents costly problems down the road.

Major renovations also warrant professional input. I’ve seen too many DIY disasters where homeowners removed what they thought was a non-load-bearing wall, only to find (the hard way) that it was actually supporting significant roof weight. If you’re removing walls, adding a second story, converting attic space, or changing your roof configuration, please consult an engineer first.

Your home will also tell you when it needs professional attention. Watch for warning signs like sagging roof lines, progressive cracks in walls or ceilings, doors or windows that suddenly stick, or unusual creaking noises during snowstorms or high winds. These are your house’s way of asking for help.

Special conditions also demand professional expertise. If you’re in an area with heavy snowfall, hurricane-force winds, seismic activity, or if you’re building something with unique architectural features, professional engineering isn’t optional—it’s essential.

Commercial properties almost always require professional engineering due to their complexity, higher occupancy loads, and stricter code requirements. The liability considerations alone make professional design a necessity.

As we like to say at DML USA, “When in doubt, consult a professional.” The cost of engineering services is minimal compared to the potential costs of structural failure—not to mention the peace of mind that comes from knowing your roof is properly designed to protect your family and property for decades to come.

Conclusion

As we wrap up our journey through roof load distribution, I hope you’ve gained valuable insights into this crucial aspect of building safety and performance. We’ve covered a lot of ground together, from the basic principles to advanced techniques, all aimed at helping you understand how your roof handles the forces nature throws at it.

Think about what we’ve learned: your roof isn’t just a static cap on your home—it’s a dynamic system that constantly works to channel forces safely through your building’s structure. When designed and maintained properly, this system protects everything (and everyone) beneath it with quiet efficiency.

The safety implications simply can’t be overstated. Proper roof load distribution prevents the kinds of structural failures that can lead to costly damage or even dangerous collapses. This isn’t abstract engineering theory—it’s practical knowledge that protects lives and property.

Remember those different load types we discussed? The dead loads of your roofing materials, the live loads of maintenance workers or accumulated snow, and the environmental forces like wind and rain all interact in complex ways. Each demands attention and respect in your roof’s design.

That continuous load path—from roofing material to sheathing to rafters to walls to foundation—forms the backbone of structural integrity. Like a chain, it’s only as strong as its weakest link, which is why every connection matters.

Your choice of roofing material makes a tremendous difference too. As we’ve seen, metal roofing offers compelling advantages in terms of weight, durability, and performance. Its lightweight nature reduces the dead load on your structure while still providing exceptional resistance to environmental forces.

Building codes exist for good reason—they represent the collective wisdom gained from decades of structural successes and failures. Meeting or exceeding these standards isn’t just about legal compliance; it’s about embracing proven practices that ensure safety and performance.

Maintenance isn’t optional either. Regular inspections and proactive care preserve your roof’s load-handling capabilities throughout its lifespan. Small issues, when caught early, rarely become major structural problems.

While DIY knowledge is valuable, some situations absolutely call for professional expertise. Knowing when to call in an engineer or roofing professional is itself an important skill for any building owner.

Here at DML USA Metal Roofing, we’re passionate about creating roofing systems that excel at roof load distribution. Our metal roofing solutions are engineered specifically for Illinois conditions, offering the perfect balance of lightweight construction and extraordinary strength. Our systems shed snow efficiently, resist wind uplift, and provide decades of reliable service with minimal maintenance requirements.

The energy efficiency of our metal roofing systems isn’t just good for the environment—it can qualify you for valuable tax credits while reducing your energy bills year after year. That’s protection and performance working hand in hand.

Whether you’re building new construction, renovating an existing structure, or addressing specific concerns with your current roof, understanding roof load distribution empowers you to make better decisions. The principles we’ve explored together form the foundation of roof systems that don’t just survive—they thrive through decades of service.

For more information about our metal roofing products and how they can improve your building’s roof load distribution, visit our products page or reach out to our Illinois-based team. We’re always happy to discuss your specific needs and how our solutions can address them.

When it comes to your roof, proper load distribution isn’t just engineering jargon—it’s the science behind your family’s safety and your home’s longevity. It’s peace of mind during every storm, every winter, and every year you spend in your home.