3 tab shingles wind resistance: 5 Proven Tips for Superior Protection 2025

When Shingles Face the Storm: Understanding Wind Resistance

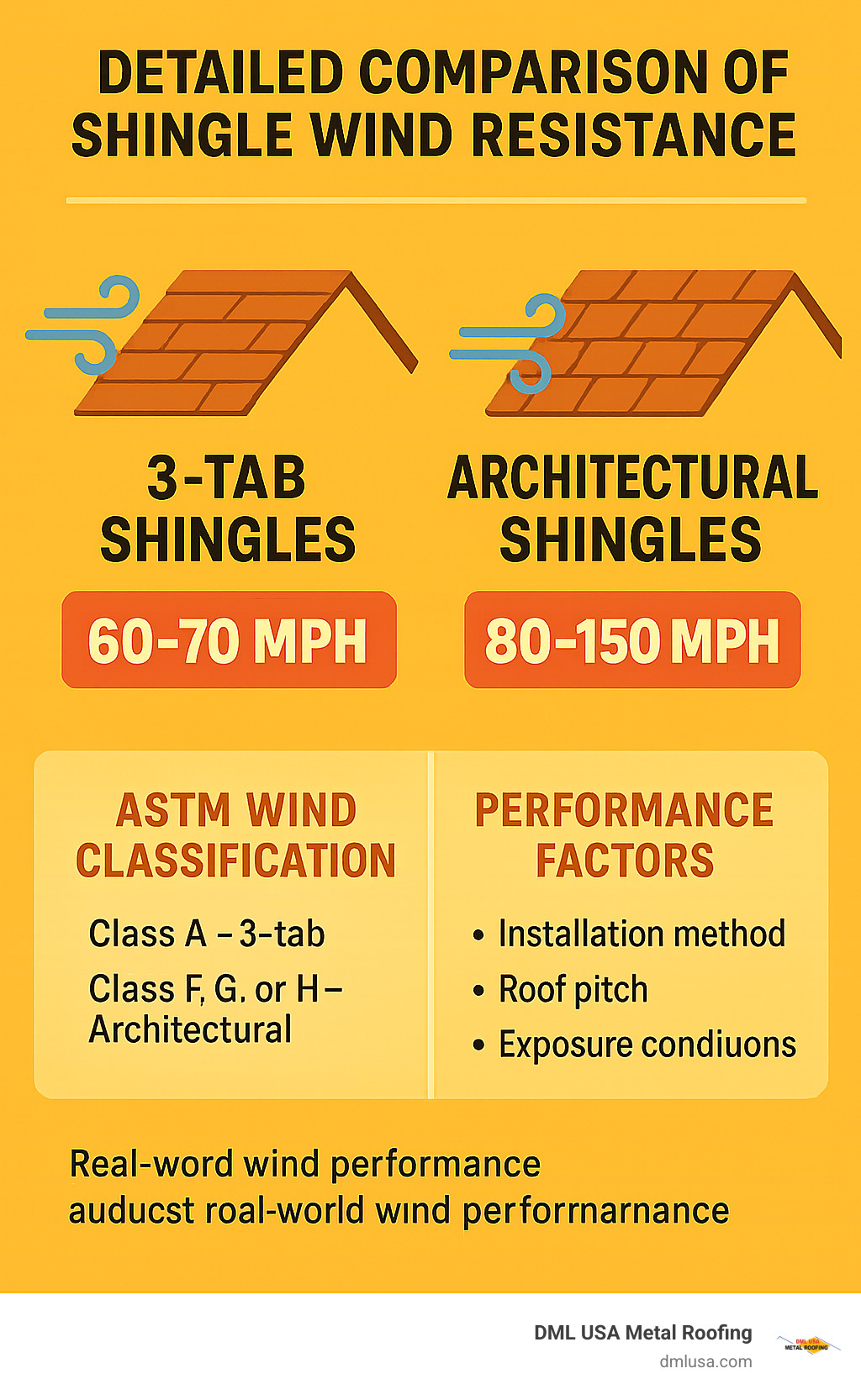

3 tab shingles wind resistance ratings typically range from 60-70 mph when installed with standard nailing patterns, while architectural shingles can withstand 80-150 mph winds depending on their classification.

| Shingle Type | Standard Wind Rating | Improved Installation Rating |

|---|---|---|

| 3-Tab | 60 mph (Class A) | Up to 70 mph (with 6 nails) |

| Architectural | 110-130 mph (Class F/G) | Up to 150 mph (Class H) |

Picture this: you’re sitting comfortably in your living room when a storm rolls in. The wind picks up, whistling around your home’s corners. Are you confident your roof can handle what’s coming? For many homeowners, that question brings more anxiety than it should.

I’ve seen it time and again – homeowners caught off guard when their shingles start lifting after winds that weren’t even hurricane-strength. The frustration in their voices is always the same: “I thought my roof could handle this.”

The reality is that not all asphalt shingles are created equal when it comes to standing up to Mother Nature’s fury. The difference between a roof that weathers the storm intact and one that ends up partially in your neighbor’s yard often comes down to understanding what those wind resistance ratings actually mean for your home.

Why does this matter? Because replacing damaged shingles after every strong windstorm quickly becomes a drain on your wallet – not to mention the potential water damage that can occur if those missing shingles aren’t promptly replaced. It’s a headache no homeowner needs.

I’m Adam Kadziola from DML USA Metal Roofing, and I’ve spent years helping homeowners understand the critical differences in 3 tab shingles wind resistance compared to other roofing options. Since 2007, our company has manufactured metal roofing products designed to outperform traditional asphalt in challenging weather. During that time, I’ve had countless conversations with homeowners who wished they’d understood wind ratings before their roof failed them.

If you’re concerned about wind damage to your roof, you might also want to explore our resources on hurricane proof roofs and overall roof wind resistance to better protect your investment.

The peace of mind that comes with knowing your roof can stand up to what Mother Nature throws at it? That’s truly priceless. In the following sections, we’ll dive deeper into what makes a shingle wind-resistant and how to maximize the protection for your home – whether you choose traditional asphalt or decide to upgrade to a more durable alternative.

1. What Are 3-Tab Shingles?

When you drive through most American neighborhoods, you’re likely seeing 3-tab shingles on many of the roofs. These classic roofing materials earned their straightforward name from their design – each shingle strip has two cuts that create three equal-sized tabs, giving your roof that familiar, clean pattern.

Think of 3-tab shingles as the reliable sedan of roofing materials – not flashy, but they get the job done. They start with a fiberglass mat that manufacturers coat with asphalt and top with ceramic granules. Those granules aren’t just for looks – they shield your roof from harmful UV rays while providing that classic speckled color.

What makes 3-tab shingles popular with budget-conscious homeowners? For starters, they’re lightweight, typically between 50-80 pounds per square (that’s roofing talk for 100 square feet). Their uniform appearance creates that neat, symmetrical look many homeowners appreciate. The single layer design keeps them thin – about 3/16 inch – which contributes to their cost-effectiveness.

An important feature for 3 tab shingles wind resistance is the sealant strip running along each shingle. This adhesive activates in warm weather, helping tabs bond together and resist wind uplift. Think of it as nature’s glue gun – the sun warms it up, and your shingles stick together better.

How They Differ from Architectural Shingles

If 3-tab shingles are the sedan of roofing, architectural shingles are more like the luxury SUV. Also called dimensional or laminate shingles, these premium options bring more substance to your roof in every way.

The biggest difference? Layers! While 3-tabs are cut from a single layer, architectural shingles are built by laminating multiple layers of asphalt and fiberglass together. This sandwich approach creates a thicker, more substantial product that casts appealing shadows and dimension across your roof.

The differences go beyond just looks. Architectural shingles are typically twice as thick as 3-tabs and about 50% heavier – weighing in at 350-450 pounds per square. This extra heft isn’t just for show; it significantly improves their wind resistance and durability.

Your wallet will notice the difference too. Architectural shingles generally cost 20-40% more upfront, but they often last significantly longer – typically 30-50 years compared to 15-25 years for 3-tabs. Their varied dimensions create that upscale, textured look that many newer neighborhoods require.

As one roofing contractor explained to me at a trade show last year, “It’s simple physics – more material means more resistance. When strong winds hit, those lightweight 3-tabs can lift more easily than their heavier architectural cousins.”

This fundamental difference in weight and construction explains much about why 3 tab shingles wind resistance ratings typically fall below their architectural counterparts – a crucial consideration for homeowners in windy regions.

2. How 3 Tab Shingles Wind Resistance is Rated

Ever wonder how manufacturers determine those wind ratings on your shingle packaging? Let’s explain how 3 tab shingles wind resistance is actually measured and what those numbers mean for your home.

When wind whips across your roof, it creates a surprising effect – uplift. Just like an airplane wing generates lift, wind flowing over your shingles creates pressure differences that try to pull them right off your roof. This is exactly what industry testing aims to measure.

The roofing industry relies on two main testing standards: ASTM D7158 and ASTM D3161. These standardized tests, developed by ASTM International, simulate real-world conditions to see how well shingles stay put when the wind starts howling.

During testing, technicians seal shingle samples just as they would be on your roof, then subject them to controlled wind conditions. For the ASTM D7158 test, shingles face wind velocities of about 35 mph, and researchers measure their mechanical uplift resistance. Using this data, they can calculate how the shingles would likely perform in much stronger winds. For more detailed information on these testing methods, you can review the ASTM D7158 standard specifications.

Understanding Class Labels and MPH Numbers

When shopping for shingles, you’ll notice letter classifications that correspond to specific wind speeds. Here’s what they actually mean:

ASTM D3161 Classifications:

– Class A: Holds tight in winds up to 60 mph

– Class D: Remains secure in winds up to 90 mph

– Class F: Withstands powerful winds up to 110 mph

ASTM D7158 Classifications:

– Class G: Handles strong winds up to 120 mph

– Class H: Survives extreme winds up to 150 mph

Most standard 3-tab shingles earn a modest Class A rating (60 mph) when installed with the basic 4-nail pattern. Some premium options like CertainTeed XT 30 IR can reach 70 mph, but as one roofing expert noted in a technical forum, “To my knowledge, no 3-tab shingle is rated by the manufacturer for more than 60 MPH” using standard installation methods.

3 Tab Shingles Wind Resistance vs Architectural Shingles

When it comes to standing up to Mother Nature, not all shingles are created equal. The difference between 3 tab shingles wind resistance and architectural shingles is quite dramatic:

| Feature | 3-Tab Shingles | Architectural Shingles |

|---|---|---|

| Standard Wind Rating | 60-70 mph | 110-130 mph |

| Improved Installation Rating | Up to 90 mph | Up to 150 mph |

| Weight Advantage | Lighter | 50% heavier (better wind resistance) |

| Sealant Area | Limited by tab design | Larger continuous sealant strips |

| Tab Exposure | More exposed edges | Fewer exposed edges |

| Cost | $$ | $$$ |

Why such a big difference? It comes down to physics. Architectural shingles simply have more going for them when the wind kicks up. Their greater mass makes them harder for wind to lift – imagine trying to blow a piece of cardboard versus a heavy book off a table. They also have stronger sealant bonds with larger adhesive areas creating better connections.

With fewer exposed edges, architectural shingles give wind less opportunity to get underneath and start the lifting process. Their thicker material also provides more rigidity, helping them resist deformation when wind pressure builds.

As noted in a 2023 industry comparison, “Architectural shingles use finer-grade asphalt and stronger adhesives, extending lifespan and warranty lengths.” These quality improvements directly translate to better performance when storms roll in.

Interestingly, GAF’s Royal Sovereign 3-tab shingles are somewhat of an exception, carrying impressive ASTM D7158 Class H (up to 150 mph) and ASTM D3161 Class F (up to 110 mph) ratings. This shows that with advanced manufacturing techniques, even basic 3-tab designs can achieve remarkable wind resistance – though they remain the exception rather than the rule.

3. Five Installation Tips to Boost 3-Tab Shingle Wind Performance

While 3 tab shingles wind resistance ratings might seem modest compared to architectural options, don’t lose heart! With the right installation techniques, you can significantly improve how these shingles perform when the wind kicks up. I’ve seen properly installed 3-tab roofs withstand conditions they were never rated for, all because someone took the time to do it right.

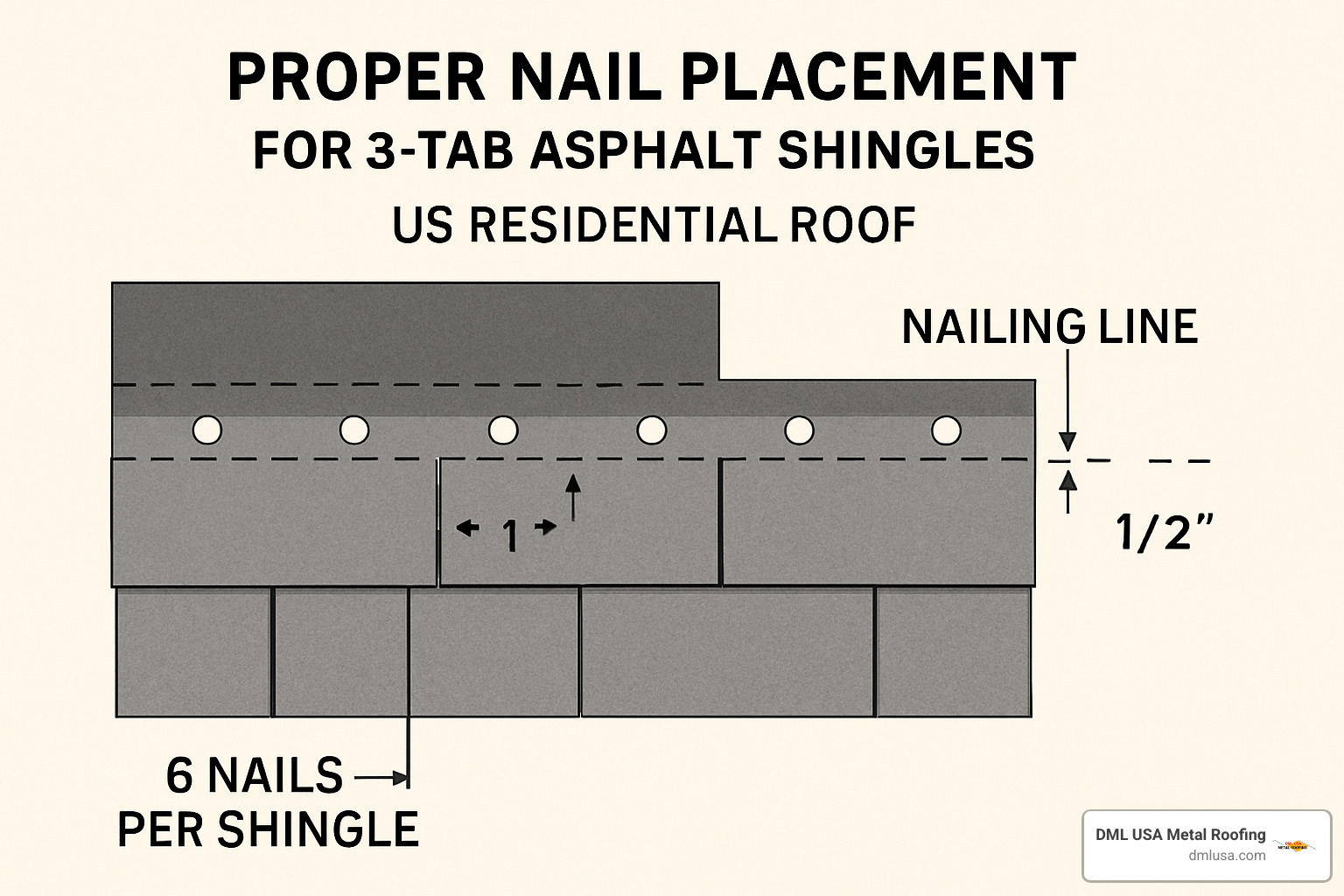

3 Tab Shingles Wind Resistance Tip #1: Use Six Nails

The standard installation of 3-tab shingles typically calls for just four nails, but here’s a secret the pros know: bumping that up to six nails can make a world of difference in windy conditions.

Think of it this way – each nail is like another anchor holding your roof down during a storm. When you place these nails correctly – about 5⅝ inches above the bottom edge along the nailing line – you’re creating a much stronger defense system. Position one nail about an inch from each end, then space the remaining four evenly between them.

The type of nail matters too. Ring-shank roofing nails with at least a 3/8-inch head diameter give you the best grip. Make sure they penetrate at least 3/4 inch into your roof deck for maximum holding power.

As one weathered roofing professional told me at a trade show, “The six-nail pattern essentially doubles your holding power. It’s like having a backup plan for each part of the shingle.” This approach has historical backing too – before the 2001 International Building Code, the SBCCI 1997 code actually required six nails per shingle in areas prone to high winds.

3 Tab Shingles Wind Resistance Tip #2: Hand-Seal Each Tab

Have you ever noticed that strip of factory-applied adhesive on your shingles? It’s designed to activate when warmed by the sun, creating a seal that helps keep shingles in place. But in high-wind areas or during cold-weather installation, this natural sealing process might not be enough.

That’s where manual sealing comes in. By applying quarter-sized spots of ASTM D4586 Type II asphalt roofing cement under each tab, you create an immediate bond that doesn’t need to wait for warm weather. For 3-tab shingles, place four spots equally spaced under each tab.

Just be careful not to go overboard – too much cement can actually cause blistering. As one contractor from the Midwest told me, “In high-wind zones, we put a dab of roofing cement under each tab corner. It’s cheap insurance against blow-offs, especially during that vulnerable period before the factory seal activates.”

Beyond these two major tips, three more installation practices can significantly boost your 3 tab shingles wind resistance:

Proper starter strips make a huge difference. These specialized starter shingles create a stronger first-row seal that prevents wind from getting underneath at the eaves. Many DIYers skip this step, but it’s absolutely crucial for wind resistance.

Sealed ridges and hips deserve extra attention too. These liftd areas catch more wind than the main roof surface, so proper sealing and fastening here pays dividends during storms.

Balanced attic ventilation might seem unrelated to wind resistance, but it actually prevents pressure buildup under your roof during storms. When high winds create negative pressure zones, proper ventilation helps equalize the forces trying to lift your shingles.

And don’t forget to install drip-edge metal. This simple addition provides crucial support at roof edges where wind uplift forces are strongest.

For more detailed guidance on these installation techniques, check out our Resources page where we dive deeper into proper roofing practices.

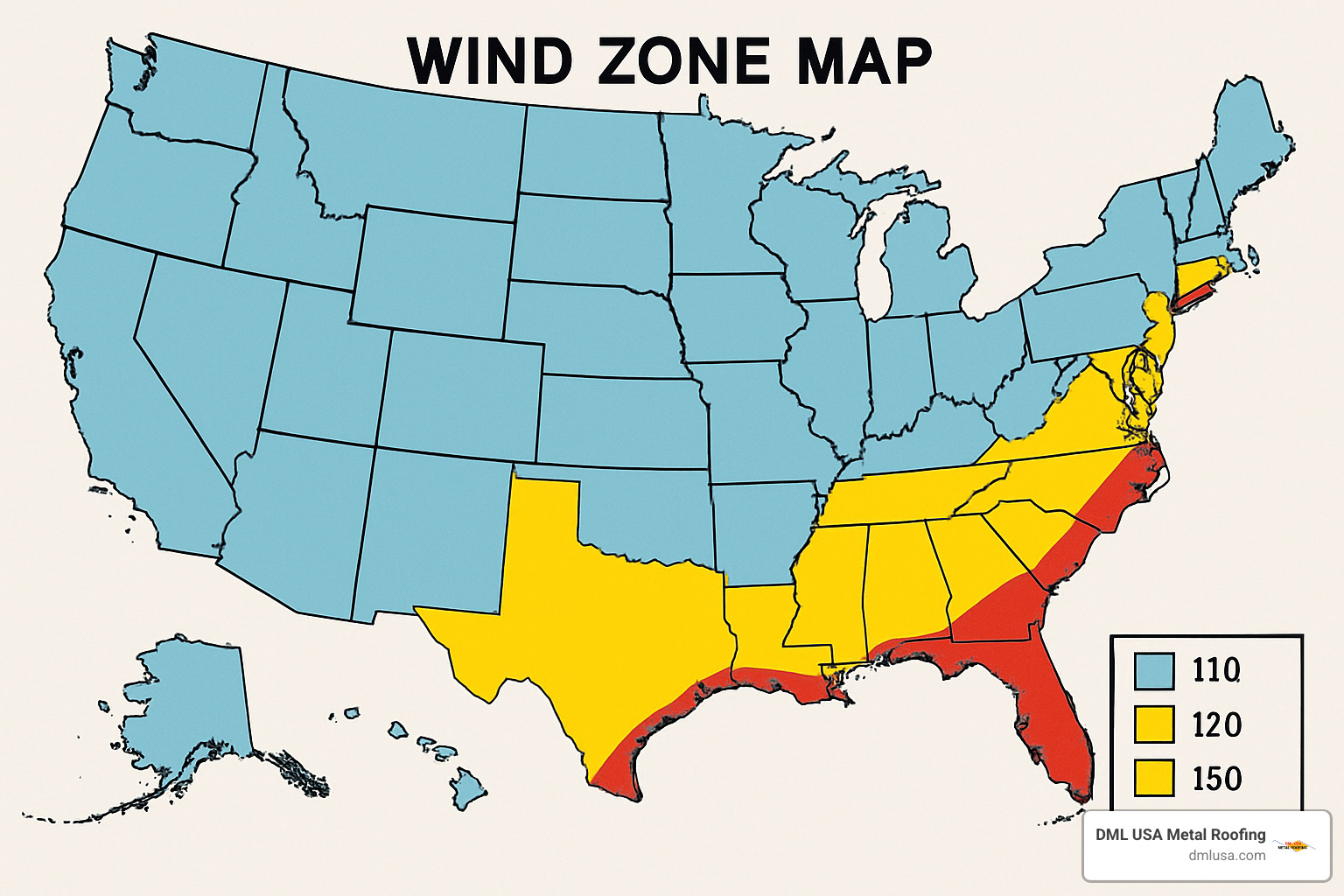

4. Codes, Warranties, and High-Wind Zones

Building codes aren’t just bureaucratic red tape – they’re your home’s first line of defense against nature’s fury. The International Building Code (IBC) and International Residential Code (IRC) section 1609 set clear guidelines about what roofing materials are appropriate for different wind zones across the country.

These codes reference ASCE 7 standard wind speed maps that divide the United States into different risk zones. If you live along the Gulf or Atlantic coasts, you’re likely in one of the highest design wind zones, where speeds commonly exceed 120-140 mph during severe weather events.

Here’s the reality check many homeowners don’t realize: for areas with design wind speeds above 60 mph (which includes most of America), standard 3-tab shingles with basic four-nail installation often fall short of code requirements. This isn’t just a technical detail – it’s the difference between your roof staying put or becoming airborne during the next big storm.

What Happens If You Exceed the Rated MPH?

Installing shingles in areas where winds regularly exceed their rated capacity is like buying tires rated for 60 mph and driving 90 mph on the highway – something’s bound to fail, and it won’t be pretty.

First, you can kiss your warranty goodbye. As one straight-talking industry expert put it, “If 60 MPH max shingles are installed in a 90MPH wind zone, I’ll bet a lot of manufacturers are not going to stand behind the warranty.” They’ve rated their product for specific conditions, and exceeding those limits gives them an easy out.

Your insurance company might also leave you high and dry. When adjusters review wind damage claims, they often check whether your roofing materials were appropriate for your location. Finding inappropriate materials gives them grounds to deny your claim when you need help most.

Beyond paperwork problems, 3 tab shingles wind resistance limitations mean real-world failure when pushed beyond their ratings. The sealant strips fail first, allowing wind to get underneath the tabs. Once that happens, it’s only a matter of time before you’re picking up pieces of your roof from your yard – or your neighbor’s.

Perhaps most concerning for homeowners: installations that don’t meet local wind-resistance requirements may violate building codes. This can lead to failed inspections or major complications when selling your home down the road.

Improved 3-Tab Products for Coastal or Hurricane Areas

Not all 3-tab products are created equal. Some manufacturers have recognized the need for better options in wind-prone regions and developed improved versions that stand up to Mother Nature’s temper tantrums.

GAF Royal Sovereign shingles are the standout performers in the 3-tab category, carrying impressive ASTM D7158 Class H (150 mph) and ASTM D3161 Class F (110 mph) ratings – numbers that rival or exceed many architectural shingles.

Some manufacturers have gone back to the drawing board to create reinforced 3-tab options with stronger fiberglass mats and improved adhesive systems specifically designed for coastal applications. These products often feature double sealant lines that create a more tenacious grip on your roof deck.

One coastal homeowner shared a surprising success story on an industry forum: “CertainTeed XT25 shingles remained firmly attached to my beach house after a Category 1 hurricane, despite questions about their use in our wind zone.” While this anecdote is encouraging, it’s always safer to choose products explicitly rated for your area’s conditions.

For truly hurricane-prone locations, however, most roofing professionals recommend upgrading to architectural shingles at minimum. Better yet, consider metal roofing alternatives that offer superior wind resistance without the inherent vulnerabilities of tab-style products. The initial investment might be higher, but the long-term peace of mind is priceless when storm clouds gather on the horizon.

5. Spotting and Preventing Wind Damage

Early detection of wind damage can save you thousands in repair costs and prevent water damage to your home’s interior. When it comes to 3 tab shingles wind resistance, knowing what to look for after a storm can make all the difference.

I’ve seen countless roofs where homeowners missed the early warning signs until water started dripping through their ceiling. Don’t let that be you! The most common sign of wind damage is lifted tabs – those corners that have broken their seal with the course below. This happens when wind forces work their way under the shingle and break the adhesive bond.

Creased shingles tell an interesting story too. They indicate your shingles experienced enough wind force to temporarily fold backward but managed to return to position. Think of it like a warning shot – your roof survived this time, but those creased areas are now vulnerable to future storms.

When you spot missing tabs or entire shingles, that’s your roof waving a red flag. This means the wind has already exceeded your shingles’ resistance capacity, and immediate action is needed. Similarly, excessive granule loss might look harmless, but those tiny mineral particles are your shingles’ first line of defense against UV rays and weather.

Torn or split tabs often appear after particularly violent gusts, while exposed nails indicate the shingles have shifted enough to reveal their fasteners. Don’t overlook damaged flashing either – those metal pieces around chimneys and vents are critical for keeping water out.

| Damage Sign | Likely Cause | Urgency Level |

|---|---|---|

| Lifted tabs | Sealant failure | Moderate – repair soon |

| Missing shingles | Wind exceeding rating | High – immediate repair |

| Granule loss | Age + wind abrasion | Low to moderate |

| Creased shingles | Temporary wind uplift | Moderate – monitor |

| Torn shingles | Aging + high winds | High – repair needed |

Annual Roof Checklist for Homeowners

I always tell my customers that maintaining 3 tab shingles wind resistance is a lot like taking care of your car – regular check-ups prevent major breakdowns. Here’s my simple annual roof maintenance routine:

Grab a pair of binoculars for a visual scan from ground level. This lets you spot issues without risking a fall. Look systematically across your roof, focusing on areas where shingles might be missing, damaged, or lifting.

Don’t forget to check your attic on a sunny day. Light streaming through where it shouldn’t be is a clear sign of trouble. While you’re up there, look for water stains or drafts that might indicate compromised areas.

Pay special attention to roof edges and flashing. These transition areas are particularly vulnerable to wind damage. The edges of your roof experience the strongest uplift forces during storms, so they often show damage first.

After any significant windstorm, take ten minutes for a quick post-storm assessment. As one of my customers in Oklahoma told me, “I’d rather spend ten minutes looking at my roof than ten thousand dollars replacing my water-damaged ceiling.”

Consider scheduling a professional evaluation every 2-3 years. A trained eye can spot developing issues that most homeowners miss. It’s money well spent, especially as your roof approaches the 10-year mark.

Keep a visual record by taking dated photos of your roof annually. This makes it easier to track subtle changes over time and can be invaluable for insurance claims if damage does occur.

“Even if the weather is sunny and warm, a sudden bout of wind can blow off shingles quickly. Regular inspections are your best defense,” explains a veteran roofing contractor I work with regularly.

For 3-tab shingles specifically, the adhesive seal between courses is your roof’s first line of wind defense. As these shingles age, that bond naturally weakens, making your roof increasingly vulnerable to wind damage. That’s why checking sealant integrity becomes more important with each passing year.

Catching minor issues early can extend your roof’s lifespan by years. And if you’re thinking about a more wind-resistant alternative, our metal roofing options at DML USA provide exceptional protection against even the strongest storms.

Frequently Asked Questions about 3 Tab Shingles Wind Resistance

Are there any 3-tab shingles rated for 110 mph?

Yes, some premium 3-tab shingles do achieve the impressive 110 mph rating (Class F). GAF’s Royal Sovereign line stands out as one of these exceptional products. While most standard 3-tab shingles tap out at 60-70 mph wind resistance, these high-performance options push the boundaries of what traditional 3-tabs can handle.

I spoke with a contractor who installed these premium shingles on a lakefront property last year. He shared that “Underwriters Laboratories tests prove that after two hours of sustained 110 mph (177 kph) winds, the Hurricane shingle suffered no damage.” Pretty remarkable for a 3-tab product!

Though, these upgraded 3-tabs often come with a price tag approaching entry-level architectural shingles. You’ll need to weigh whether the traditional 3-tab appearance is worth the similar cost, or if stepping up to architectural shingles might make more sense for your home and budget.

Will adding extra nails void my shingle warranty?

Good news – adding extra nails typically won’t void your warranty. In fact, upgrading from the standard four nails to six nails per shingle is specifically recommended by many manufacturers for homes in windier regions.

To keep your warranty intact while improving wind resistance, just be sure to:

– Place nails exactly along the manufacturer’s specified nail line

– Use the correct type and size of roofing nails (usually 11- or 12-gauge with 3/8″ heads)

– Drive nails properly so they penetrate at least 3/4″ into the roof deck

As one experienced roofer told me, “I’ve never seen a manufacturer complain about extra nails when properly placed. It’s improper nail placement that causes warranty issues.” Still, it’s always smart to double-check your specific shingle manufacturer’s installation guidelines before making any changes to their recommended methods.

Should I consider metal roofing instead of high-wind shingles?

For homeowners in areas that regularly face strong winds – especially coastal regions – metal roofing deserves serious consideration. Even the best 3 tab shingles wind resistance ratings can’t match what quality metal roofing systems offer.

Metal roofing shines in several key areas compared to asphalt shingles. Most quality metal systems can withstand winds of 140-180 mph – far beyond even the best asphalt products. They also typically last 50-60 years compared to the 15-30 years you’ll get from asphalt shingles.

The math often works out in metal’s favor too. Despite the higher upfront investment, the extended lifespan and minimal maintenance requirements typically result in lower lifetime costs. Plus, those reflective coatings on metal roofs can cut your cooling costs by up to 20% – a welcome relief during Illinois summers!

An industry study I recently reviewed noted that “Metal shingles experience less blow-off in high winds despite being only one-quarter the weight of asphalt shingles.” That’s impressive engineering at work.

At DML USA Metal Roofing, we’ve helped countless Illinois homeowners make the switch after repeatedly replacing wind-damaged asphalt shingles. Many tell us they wish they’d made the change years earlier. You can learn more about these benefits on our Why Choose Metal Roofing page.

Conclusion

When it comes to 3 tab shingles wind resistance, the truth is pretty straightforward: standard 3-tab products just weren’t built for life in the fast lane. With typical ratings of only 60-70 mph, they’re the lightweight contenders in a heavyweight wind match that many regions face regularly.

I’ve seen it – homeowners investing in new 3-tab roofs only to find shingles scattered across their yards after the first significant storm. It doesn’t have to be this way!

While you can certainly boost performance with those six-nail patterns and hand-sealing techniques we discussed (and they do help!), homeowners in windier areas should really take a step back and consider their options carefully:

Match your roof to your weather. It sounds obvious, but I’m constantly surprised by how many folks install shingles rated for 60 mph in regions that regularly see 80+ mph gusts. That’s setting yourself up for disappointment and repair bills.

Architectural shingles offer that extra 50-70 mph of wind protection for a reason. Their additional weight and dimensional structure aren’t just for looks – they’re functional improvements that keep your roof intact when the weather turns nasty.

Even the best shingles fail when poorly installed. I can’t stress this enough: proper installation techniques make all the difference between a roof that lasts through storms and one that gives up at the first stiff breeze.

Regular roof inspections aren’t just for professionals. Take a few minutes after each major storm to scan your roof from the ground with binoculars. Those early warning signs we discussed can save you thousands if caught early.

For those truly tired of the shingle replacement cycle, metal roofing provides that ultimate peace of mind. Yes, it’s a bigger upfront investment, but when you’re not replacing your roof every 15-20 years, the math starts looking pretty favorable.

The difference between 3-tab and architectural shingles isn’t just about curb appeal. It’s about fundamental performance when Mother Nature tests your home’s defenses. Those dimensional layers, extra weight, and improved sealant systems on architectural shingles truly earn their keep during windstorms.

Here at DML USA Metal Roofing, we’ve heard countless stories from Illinois homeowners who finally broke the cycle of wind damage by upgrading to our metal roofing systems. Our products are specifically engineered for the challenging Midwest weather patterns – from Chicago’s famous winds to those surprise summer storms that seem to come out of nowhere.

To explore our complete range of wind-resistant metal roofing options that will stand strong for decades, visit our Products page or reach out to our friendly team in Northlake or Chicago for a no-pressure conversation about what might work best for your home.

Your roof isn’t just another home improvement project – it’s your family’s primary shield against everything nature throws your way. Choosing wisely isn’t about impressing the neighbors (though that’s a nice bonus); it’s about protecting your most valuable investment for the long haul.