Metal roofing and siding experts: Top 10 Trusted Picks 2025

Finding the Right Metal Roofing and Siding Experts for Your Home

If you’re looking for metal roofing and siding experts, here’s what to look for in a qualified professional:

- Proper Licensing & Insurance – Verify state-specific credentials

- Specialized Experience – At least 5+ years working specifically with metal

- Manufacturer Certifications – Factory-trained for specific systems

- Portfolio of Similar Projects – Ask to see completed metal installations

- Written Warranties – Both materials (25-60 years) and workmanship (5+ years)

- Clear Communication – Detailed quotes and responsive service

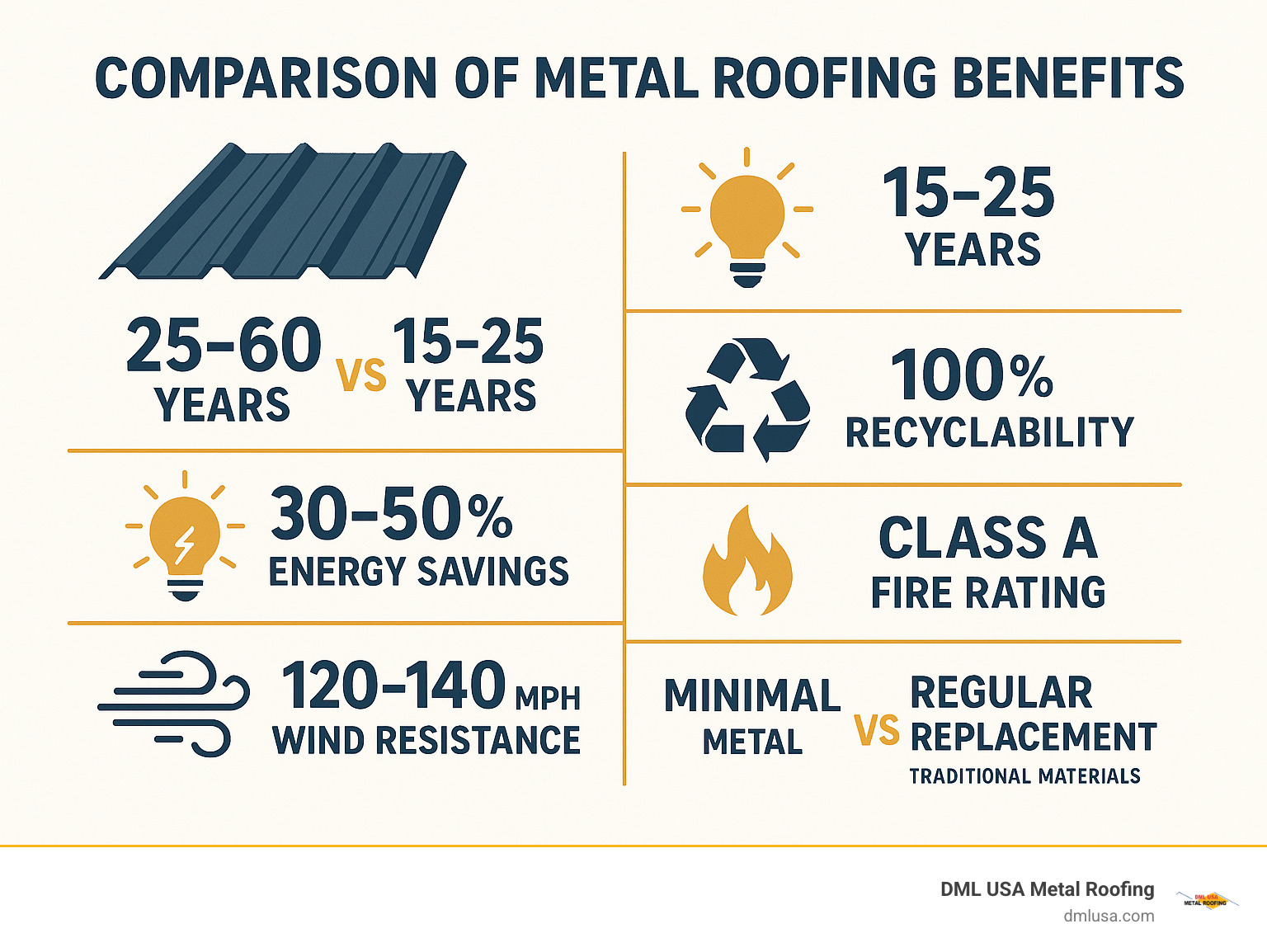

Metal roofing and siding experts bring specialized knowledge to your project that general contractors often lack. Their expertise ensures proper installation techniques that maximize the impressive 25-60 year lifespan of quality metal systems, compared to just 15-20 years for traditional materials.

Metal systems offer exceptional durability against harsh weather, significant energy savings through reflective surfaces, and virtually maintenance-free performance. While the initial investment is higher than conventional materials, the long-term value is undeniable when installed by qualified professionals.

My name is Adam Kadziola, founder of DML USA Metal Roofing, where our team of metal roofing and siding experts has been manufacturing and installing high-quality, affordable metal roofing systems throughout Illinois since 2007.

Terms related to metal roofing and siding experts:

– metal roof coating companies

– metal roofing installation companies

– commercial metal roofing contractors

Certified & Accredited Pros

When you’re investing in a metal roof or siding system, the team installing it matters just as much as the materials themselves. Finding genuine metal roofing and siding experts isn’t just about who offers the lowest bid—it’s about who brings the right credentials to your project.

At DML USA Metal Roofing, we believe that proper certification reflects a commitment to excellence that shows up in every seam, fastener, and trim piece we install. Our experienced teams combine years of hands-on knowledge with formal training that keeps them at the cutting edge of industry standards.

“A properly installed and maintained commercial metal roof can last between 25 and 60 years,” notes a recent industry study. But here’s the truth: that impressive lifespan only happens when your installation team knows exactly what they’re doing.

Our Illinois-based crews carry comprehensive insurance coverage that exceeds state requirements, including general liability and workers’ compensation. This protects both your property and our team members throughout the installation process—giving you one less thing to worry about.

Why hire true metal roofing and siding experts

There’s a world of difference between a general contractor who “can do metal roofs” and dedicated metal roofing and siding experts who specialize in these systems. This difference becomes crystal clear in the quality and longevity of your finished project.

When you work with true specialists like our team at DML USA, you’re getting craftspeople who understand the nuances of different metal systems. We know exactly how to achieve watertight seals at every junction and how to adjust installation techniques for Illinois’ challenging weather patterns—from summer heat waves to winter freeze-thaw cycles.

One of our Chicago clients put it perfectly: “The attention to detail made all the difference. Their crew knew exactly how to handle the custom trim around our complex roofline, something our previous contractor couldn’t figure out.”

Metal roofing and siding experts also provide meaningful workmanship warranties, giving you confidence that your investment is protected. We stand behind our installations because we know they’re done right the first time, with proper code compliance built into every project.

Our specialized knowledge extends to material-specific techniques—whether we’re installing standing seam panels, corrugated systems, or metal shingles. Each requires its own approach, and our teams are trained in all of them.

Key certifications to look for

When vetting potential installers, these credentials separate true metal roofing and siding experts from general contractors:

NRCA Membership signals that a contractor stays current with the National Roofing Contractors Association’s best practices and technical updates. This industry leadership organization sets the standards that professionals follow.

VSI Certification from the Vinyl Siding Institute demonstrates versatility in exterior cladding expertise—important for contractors who handle both metal and vinyl systems.

OSHA Compliance ensures that safety protocols meet federal standards, protecting both workers and your property during installation.

Perhaps most crucial are manufacturer factory-certified crews. These credentials confirm that installers have received specific training on the exact systems they’re installing. As our lead installer with over 20 years of experience explains, “When you hire factory-certified installers, you’re not just getting workers—you’re getting craftsmen who understand the engineering behind the system.”

Don’t be shy about asking for proof of these certifications before signing any contract. Legitimate metal roofing and siding experts like our team at DML USA will happily share our credentials and explain how our specialized training benefits your specific project.

More info about installation standards

Design-Driven Fabricators

The best metal roofing and siding experts don’t just install products—they help create custom solutions that transform your vision into reality. This design-driven approach is at the core of what separates exceptional metal contractors from average ones.

At DML USA Metal Roofing, our Illinois-based fabrication facilities allow us to craft custom profiles that perfectly match your architectural dreams. Rather than limiting you to off-the-shelf options, we can produce panels with unique dimensions, reveals, and eye-catching features that make your property stand out.

“Metal siding and roofing panels are available in a wide variety of colors and finishes, allowing for extensive visual customization,” notes an industry report. This versatility gives you unprecedented creative freedom, whether you’re a homeowner looking to express your personal style or an architect with a bold vision.

Turning vision into reality with metal roofing and siding experts

True metal roofing and siding experts bridge the gap between imagination and implementation. When you work with our design-driven team, the process unfolds naturally:

We start with a friendly consultation where we listen to your ideas and goals. Using advanced color visualizers and 3D modeling, we help you see your project come to life before a single panel is produced. It’s like trying on clothes before you buy them—but for your building!

Our manufacturing capabilities go far beyond basic panels. Need gracefully curved panels for a radius roof? No problem. Looking for custom trim and flashings to highlight architectural details? We’ve got you covered. Dreaming of mixed-media façades that combine metal with other materials? That’s where we shine.

For larger projects, especially those with long panel runs, we’ll even bring our roll-forming equipment directly to your site. This allows for continuous panels without seams and reduces the risk of damage during transport.

A recent commercial project in Chicago shows this approach in action. The architect envisioned a façade with varying metal panel widths to create a dynamic visual rhythm. Rather than saying “that’s too complicated,” our team custom-fabricated panels in seven different widths, creating exactly the pattern the designer had in mind.

As one building developer told us, “The ability to roll-form panels on site was game-changing for our project. We eliminated transportation seams and achieved a cleaner aesthetic while actually reducing installation time.”

Comparing finish options

The finish you select for your metal roofing and siding dramatically impacts both appearance and performance. Here’s a comparison of the most popular options:

| Finish Type | Lifespan | Best For | Appearance Options | Relative Cost |

|---|---|---|---|---|

| PVDF (Kynar 500®) | 30-50 years | Maximum durability, coastal areas | Wide color range, medium gloss | Higher |

| SMP (Silicone-Modified Polyester) | 20-30 years | Budget-conscious projects with good performance | Extensive color options, high gloss available | Medium |

| Stone-Coated | 30-50 years | Traditional aesthetic with metal durability | Resembles shingles, tile, or slate | Higher |

| Bare Metal (Galvalume®) | 20-60 years | Industrial look, maximum longevity | Natural metallic appearance, weathers over time | Lower |

| Textured Finishes | Varies by base coating | Improved visual depth, hide minor imperfections | Wood grain, stucco, embossed patterns | Premium |

“What’s so cool about textured metal panels? They offer a modern, aesthetically pleasing look along with practical benefits ideal for roofing projects,” notes a recent industry article.

When you visit our showroom, you can actually touch and see these finishes for yourself. There’s something about holding a sample in your hand and seeing how it catches the light that just can’t be captured in a photograph. Our design team loves helping clients explore these options based on their specific project requirements, budget constraints, and architectural vision.

Whether you’re looking for a bold, modern statement or a subtle complement to your property’s existing character, our metal roofing and siding experts can help you find the perfect balance of beauty, performance, and value.

Energy-Efficiency & Sustainability Specialists

In today’s environmentally conscious world, the best metal roofing and siding experts understand how to maximize energy efficiency and sustainability. This expertise goes beyond basic installation to include knowledge of specialized coatings, insulation systems, and integration with other green building technologies.

“Metal roofing and siding can drastically decrease energy bills due to additional insulation and reflective surfaces,” according to industry research. At DML USA Metal Roofing, we help Illinois homeowners and businesses leverage these benefits through strategic material selection and installation techniques.

We’re not just installing metal panels – we’re creating energy-efficient building envelopes that work year-round. Many of our clients are surprised to learn that their new metal roof can qualify for valuable tax credits while supporting their net-zero goals. And for forward-thinking property owners, our solar-ready substrates make future renewable energy integration seamless.

How metal cuts utility bills year-round

Working with knowledgeable metal roofing and siding experts ensures your metal system delivers maximum energy performance in every season. The science behind the savings is fascinating – and very real.

During hot Illinois summers, our premium finishes can reflect up to 70% of solar energy, dramatically reducing cooling costs. This reflectivity is like giving your air conditioner a permanent vacation! But the benefits don’t stop there.

High emissivity is metal roofing’s secret weapon – the ability to quickly release what little heat is absorbed rather than transferring it into your building. One Chicago commercial client recently reported a 32% reduction in summer cooling costs after upgrading to our high-reflectivity metal roof system.

“The difference was immediate and significant,” they shared. “The return on investment is tracking even faster than projected.”

Winter brings its own advantages. Our installation systems incorporate thermal breaks that prevent heat transfer through fasteners and panel connections, keeping warm air inside where it belongs. When combined with appropriate underlayment and insulation, metal roofing creates an effective radiant barrier system that improves overall building envelope performance year-round.

“Metal roofs are highly durable, with finishes that resist regular wear and tear, harsh environments, and pollutants,” notes a manufacturing report. This durability means fewer replacements and less material waste over time – another way metal roofing and siding experts help you contribute to sustainability goals.

External proof of ROI

The long-term value proposition of working with qualified metal roofing and siding experts isn’t just marketing talk – it’s supported by extensive data and real-world results.

Studies consistently show buildings with properly installed reflective metal roofing can reduce cooling costs by 20-40% in summer months. That’s real money staying in your pocket, month after month, year after year.

Beyond energy savings, many of our metal roofing systems qualify for federal and state energy tax credits. Our team stays current on available incentives and can help you steer the paperwork to maximize these benefits.

Your insurance company may have a pleasant surprise for you too. Metal’s superior fire and impact resistance often qualifies homeowners for insurance discounts—sometimes up to 35%. When we talk about ROI, we’re looking at the complete financial picture.

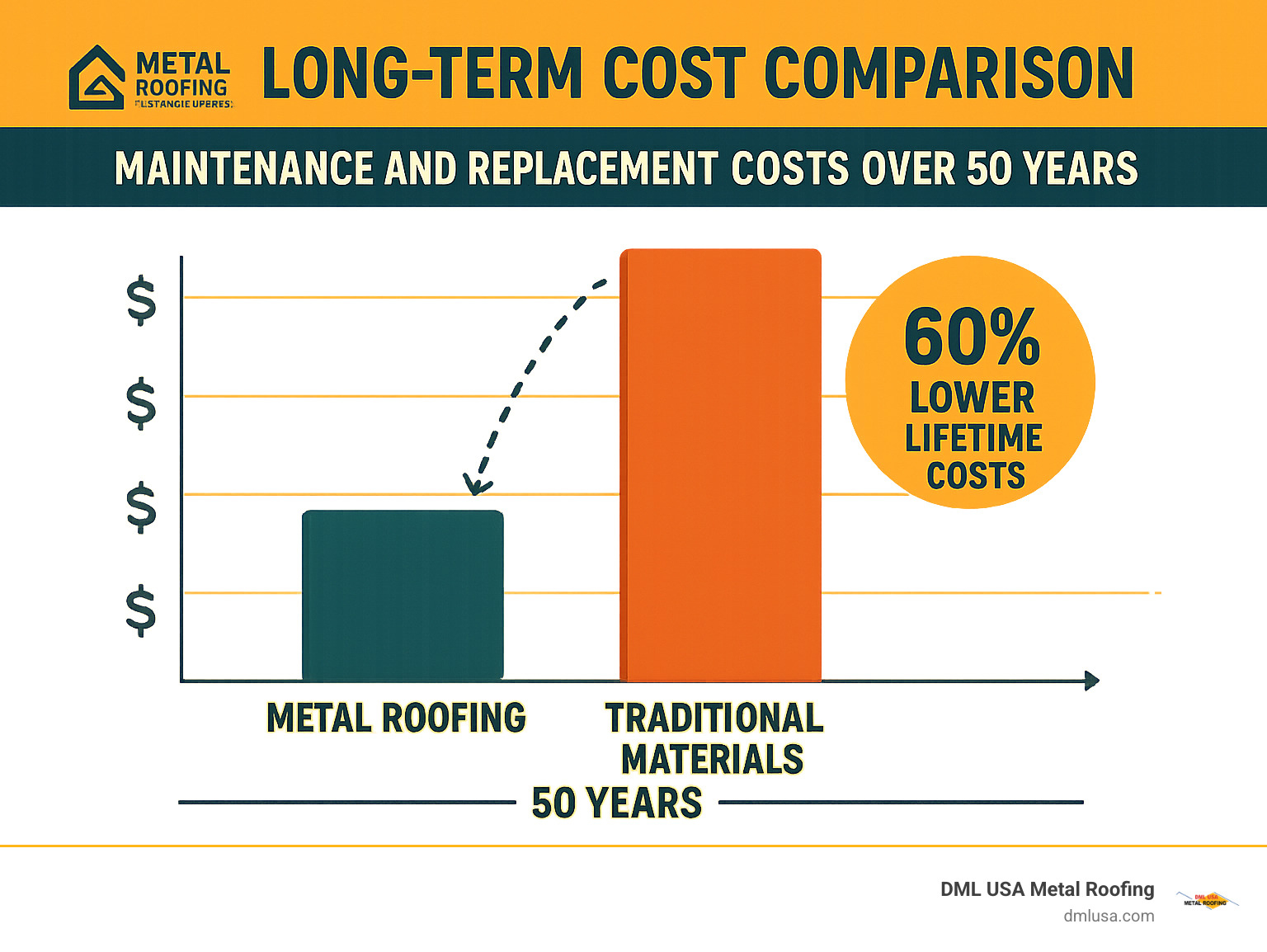

Perhaps most compelling is the lifecycle value. While initial costs are higher than conventional materials, the extended lifespan (25-60 years) and minimal maintenance requirements make metal the most economical choice long-term. Most projects reach payback within 5-7 years, with decades of additional savings thereafter.

“Metal roofing and siding panels are recyclable at the end of their lifespan, making them a sustainable building choice,” points out an environmental building assessment. This recyclability, combined with reduced energy consumption, makes metal an environmentally responsible choice you can feel good about.

At DML USA Metal Roofing, we help clients calculate their specific ROI timeline based on their building’s characteristics, local energy costs, and available incentives. We’re not just selling you a roof – we’re helping you make a smart investment in your property’s future.

Upgrading to a lifetime metal roof video

Climate-Resilient & Low-Maintenance Gurus

The value of working with experienced metal roofing and siding experts becomes particularly evident when facing extreme weather conditions. In Illinois, where we experience everything from scorching summers to freezing winters, climate resilience is a critical consideration for any exterior building system.

“Metal roofs are dent, pest, and corrosion-resistant, and can handle snow, ice, hail, and blazing sun while being energy efficient,” confirms industry research. But achieving this performance requires proper system selection and expert installation.

When you think about it, your roof takes the brunt of whatever Mother Nature dishes out. That’s why at DML USA Metal Roofing, we don’t just install metal panels—we create protective systems designed specifically for Midwest weather challenges. Our teams understand how to maximize metal’s natural resilience through thoughtful design and precision installation.

Regional performance checklist

True metal roofing and siding experts understand how to tailor systems to specific regional challenges. Here in Illinois and throughout the Midwest, weather can be unpredictable and extreme.

Freeze-thaw cycles put enormous stress on building materials. Our installation methods account for the expansion and contraction that occurs during rapid temperature changes. We use specialized fastening systems that allow for proper thermal movement to prevent buckling or fastener failure when temperatures swing wildly.

High-wind uplift resistance is crucial in the Chicago area—and not just because of our “Windy City” nickname! Our systems are engineered to exceed local wind uplift requirements through improved edge securement and strategic fastening patterns that keep everything secure even when storms blow through.

One homeowner in Oak Park told us, “During that derecho last summer, we watched shingles flying off our neighbor’s house while our metal roof didn’t budge an inch. Best investment we ever made.”

Snow load management becomes critical during our heavy Midwest winters. For sloped roofs, we incorporate snow retention systems that prevent dangerous snow slides while allowing for proper drainage. These snow guards are both functional and can be aesthetically pleasing additions to your roof design.

Hail impact resistance provides peace of mind during severe storms. Our premium metal panels and finishes are tested to withstand significant hail impacts without functional damage. Many of our systems carry Class 4 impact ratings—the highest available—which often qualifies homeowners for insurance discounts.

Wildfire protection might not seem like a primary concern in Illinois, but metal roofing’s non-combustible nature provides superior protection anywhere. As rural-urban interfaces expand, this fire resistance becomes increasingly valuable for property protection.

Maintenance made easy

Let’s be honest—nobody wants to spend their weekends maintaining their roof. One of the biggest advantages of working with qualified metal roofing and siding experts is the minimal maintenance required after installation.

While no exterior building system is truly “maintenance-free,” metal comes remarkably close. Our clients often tell us the simplicity of metal roof maintenance is a game-changer for them.

Annual visual inspections are all that’s typically needed to start. Just a simple look-over each year to catch any issues before they become problems. No special equipment required—just your eyes and maybe a pair of binoculars.

Fastener checks every 2-3 years help ensure everything stays watertight. Having fasteners inspected for proper tension and seal integrity prevents water infiltration before it can start.

Gutter cleaning remains important with any roofing system. Regular gutter maintenance prevents debris buildup that could potentially cause water to back up under metal panels. This simple task protects both your roof and foundation.

Touch-up paint is rarely needed, but we provide matching options for any scratches or minor finish damage. This maintains both the appearance and protective qualities of your metal system.

A commercial client in Northlake recently told us, “After five years, our metal roof and wall panels look virtually identical to the day they were installed. The minimal maintenance has been a significant operational cost savings compared to our previous building.”

This longevity isn’t just marketing talk—it stems from both the inherent durability of quality materials and proper installation techniques by experienced metal roofing and siding experts who understand how to maximize performance in our specific climate.

Want to learn more about how metal roofing and siding can stand up to whatever Illinois weather throws at it? Check out our Blog for seasonal maintenance tips and real-world performance stories from our customers.

Full-Service Lifecycle Partners

The best metal roofing and siding experts don’t just complete installations—they become trusted partners throughout your metal system’s entire life. At DML USA Metal Roofing, we take pride in providing comprehensive support from the moment you first contact us through decades of performance.

When you’re making a significant investment in your property, you deserve more than just installers. You need partners who’ll be there every step of the way. Like our colleagues in the industry who bring decades of specialized knowledge to their regions, our Illinois-based team approaches every project with the same level of care we’d give our own homes.

Our journey together begins with a thorough initial consultation where we take the time to understand not just what you need, but what you want your building to become. Rather than pushing cookie-cutter solutions, we educate you about options that match your specific situation. Many clients tell us this educational approach helps them feel confident in their decisions.

“I appreciated how they showed me exactly what my home would look like with different metal options,” shares a homeowner from Northbrook. “The 3D renderings made all the difference in my decision.”

Our transparent quotes break down all costs clearly—no surprises, no hidden fees, just straightforward pricing you can trust. And once your project begins, your dedicated project manager becomes your go-to person for everything related to your installation. They coordinate every detail and keep you updated throughout the process.

But our relationship doesn’t end at installation. Life happens—storms roll through, buildings expand, and needs change. When emergency repairs are needed after severe weather, our rapid-response team jumps into action. And as your building evolves, we’re here to retrofit existing systems or expand coverage for additions while maintaining that seamless look.

What great communication looks like

Have you ever played phone tag with contractors or felt completely in the dark about your project’s progress? We eliminate those frustrations through intentional communication practices that keep you informed and engaged.

Your dedicated project manager serves as your single point of contact, eliminating the confusion of multiple voices and ensuring accountability. Our crews maintain detailed daily logs documenting progress and addressing challenges, so you always know exactly where things stand.

One of our favorite moments is the post-installation walk-through, where we inspect the completed work together. This gives us a chance to explain maintenance recommendations, answer questions, and ensure you’re completely satisfied with every detail.

A Chicago business owner recently told us, “What impressed me most wasn’t just the quality of work—it was how they treated me like a partner rather than just another job.” That relationship-focused philosophy is at the heart of everything we do.

Service after the sale

The true value of working with established metal roofing and siding experts becomes crystal clear in the years following installation. Metal systems can last 50+ years, and we’re committed to helping you maximize that lifespan.

For older systems, our coating rejuvenation services can breathe new life into aging metal, extending service life and improving performance. If individual panels sustain damage from fallen branches or other accidents, we can replace just those panels without disturbing the entire system—saving you money and hassle.

We particularly enjoy helping clients through expansion projects. There’s something satisfying about ensuring perfect continuity between original installations and new additions, maintaining that seamless appearance that makes metal so attractive.

“We’ve watched clients grow from small startups to major operations,” our project director shares with pride. “One family business hired us for their initial warehouse roof back in 2010. Since then, we’ve helped them through three expansions, with each phase matching perfectly in both appearance and performance. That’s the real advantage of having a long-term partner rather than just hiring the lowest bidder.”

Frequently Asked Questions About Metal Roofing & Siding

When you’re considering metal roofing and siding experts for your home or business, questions naturally arise. After all, this is a significant investment in your property’s future! At DML USA Metal Roofing, we’ve heard it all over our years serving Illinois property owners. Let’s tackle the questions we hear most often:

How long will a metal roof or wall system last?

This is perhaps the most common question we hear – and for good reason! The longevity of metal systems is truly impressive compared to traditional materials.

When properly installed by qualified metal roofing and siding experts, you can expect remarkable lifespans: commercial metal roofs typically last 25-60 years, while premium residential systems often reach an astounding 40-70 years of service. Metal wall panels generally provide 30-50 years of protection and beauty.

“A properly installed and maintained commercial metal roof can last between 25 and 60 years, far outlasting many traditional roofing materials,” confirms industry research.

Several factors influence just how long your metal system will perform at its best. The quality of the base metal and protective coatings plays a major role – this is why we never compromise on materials at DML USA Metal Roofing. The expertise of your installation team is equally crucial (another reason to choose true metal roofing and siding experts). Local environmental conditions and following basic maintenance recommendations round out the key factors.

Our systems are specifically engineered for the unique challenges of Illinois weather. Many of our installations are expected to protect homes and businesses for 50+ years with minimal attention required. That’s peace of mind measured in decades, not years!

What does installation cost compared to shingles or vinyl?

Let’s talk straight about costs. Yes, metal systems require a higher initial investment than conventional materials – but the long-term mathematics tell a compelling story.

For residential metal roofing, expect to invest between $8-14 per square foot installed, compared to $4-7 for asphalt shingles. Commercial metal systems typically run $7-12 per square foot installed, versus $4-6 for membrane roofing. Metal wall panels generally cost $9-15 per square foot installed, while vinyl siding ranges from $4-8.

Where metal truly shines is in its remarkable long-term value. Consider these advantages:

Your maintenance costs virtually disappear – no regular repairs or upkeep expenses eating away at your budget year after year. You eliminate multiple replacement cycles – while your neighbors replace their asphalt roofs every 15-20 years, your metal roof continues performing beautifully. Energy savings of 20-40% on cooling costs make a significant difference in your monthly bills. Many insurance companies offer reduced premiums for metal roofing due to its superior durability and fire resistance. And don’t forget the 1-6% average increase in property resale value!

“Metal roofing and siding can drastically decrease energy bills due to additional insulation and reflective surfaces,” notes an industry assessment.

At DML USA Metal Roofing, we provide detailed cost-benefit analyses for each project, showing your projected lifetime savings compared to traditional materials. Most of our clients reach break-even within 7-10 years, with decades of additional savings thereafter. When you look at the complete picture, metal often becomes the most economical choice.

What maintenance is really required?

One of the greatest joys of working with qualified metal roofing and siding experts is the minimal maintenance required after installation. Unlike traditional materials that demand regular attention, metal systems are remarkably self-sufficient.

For annual maintenance, we recommend a simple visual inspection to catch any loose fasteners or sealant issues before they become problems. Take a few minutes to remove any debris from valleys, gutters, and drainage points – this prevents water from backing up where it shouldn’t. And check for any scratches or finish damage that might benefit from touch-up paint.

Every five years or so, it’s wise to have a professional inspect all penetrations and flashings, assess sealant condition at critical junctions, and verify proper panel alignment and securement. This minimal attention keeps your system performing optimally for decades.

Compare this to asphalt shingles that regularly need damaged pieces replaced, or vinyl siding that cracks and fades over time. The difference in maintenance requirements is night and day.

“Routine twice-a-year cleaning can significantly extend siding longevity,” notes a maintenance guide. With metal systems, even this minimal care is often sufficient to maintain peak performance.

One of our Chicago commercial clients recently shared: “After seven years, our maintenance costs have been less than $500 total—just a few minor adjustments after an unusually severe storm. Compared to our previous building with a membrane roof that required annual repairs, the difference is remarkable.”

Conclusion

Selecting the right metal roofing and siding experts is the critical first step in ensuring your project’s success. Throughout this guide, we’ve seen how the expertise, certification, and service approach of your chosen contractor directly impacts everything from day-one installation quality to decades of performance.

At DML USA Metal Roofing, our Illinois-based team brings a passion for metal that shows in everything we do. From our manufacturing facilities in Northlake to our installation crews serving Chicago and surrounding communities, we’re not just installing panels – we’re building protection for your most valuable assets.

Think of working with dedicated metal roofing and siding experts as an investment in peace of mind. When storms roll through Illinois, you’ll rest easier knowing your roof was installed by professionals who understand our unique climate challenges. When summer heat waves hit, you’ll appreciate the energy savings from properly installed reflective systems that keep cooling costs manageable.

“My only regret is not making the switch to metal sooner,” shared a recent customer in Schaumburg. “The difference in quality between my previous contractor and the DML team was night and day.”

The advantages of partnering with true metal roofing and siding experts extend far beyond installation day:

Your metal system will achieve its full 25-60 year potential lifespan rather than failing prematurely due to installation errors. Your home will stay cooler in summer and warmer in winter thanks to properly executed energy-efficient techniques. Your property will stand strong against Illinois weather, from summer storms to winter snow loads. And your vision will be realized through custom fabrication capabilities that turn architectural dreams into beautiful reality.

Perhaps most importantly, you’ll gain a long-term partner who stands behind their work year after year. When you need maintenance advice, expansion support, or help after severe weather, we’ll be here – just as we’ve been for Illinois homeowners and businesses since 2007.

We invite you to experience the difference that working with dedicated metal roofing and siding experts can make. Reach out to the DML USA Metal Roofing team to discuss your project, and find why so many Illinois property owners trust us with their most important building investments.