The Evolution of Advanced Roofing Solutions

Remember when roofs were just… roofs? Those days are long gone! Today’s advanced roofing solutions are engineering marvels designed to tackle challenges that traditional roofing simply can’t handle.

I’ve spent years watching the commercial roofing landscape transform, and let me tell you – it’s nothing short of revolutionary. Modern commercial buildings face a perfect storm of challenges: increasingly severe weather events, skyrocketing energy costs, and building codes that get stricter every year.

The good news? The roofing industry has stepped up in remarkable ways.

While conventional roofing typically gives up after 15-20 years of service, today’s advanced roofing solutions often double that lifespan. But longevity is just the beginning of the story.

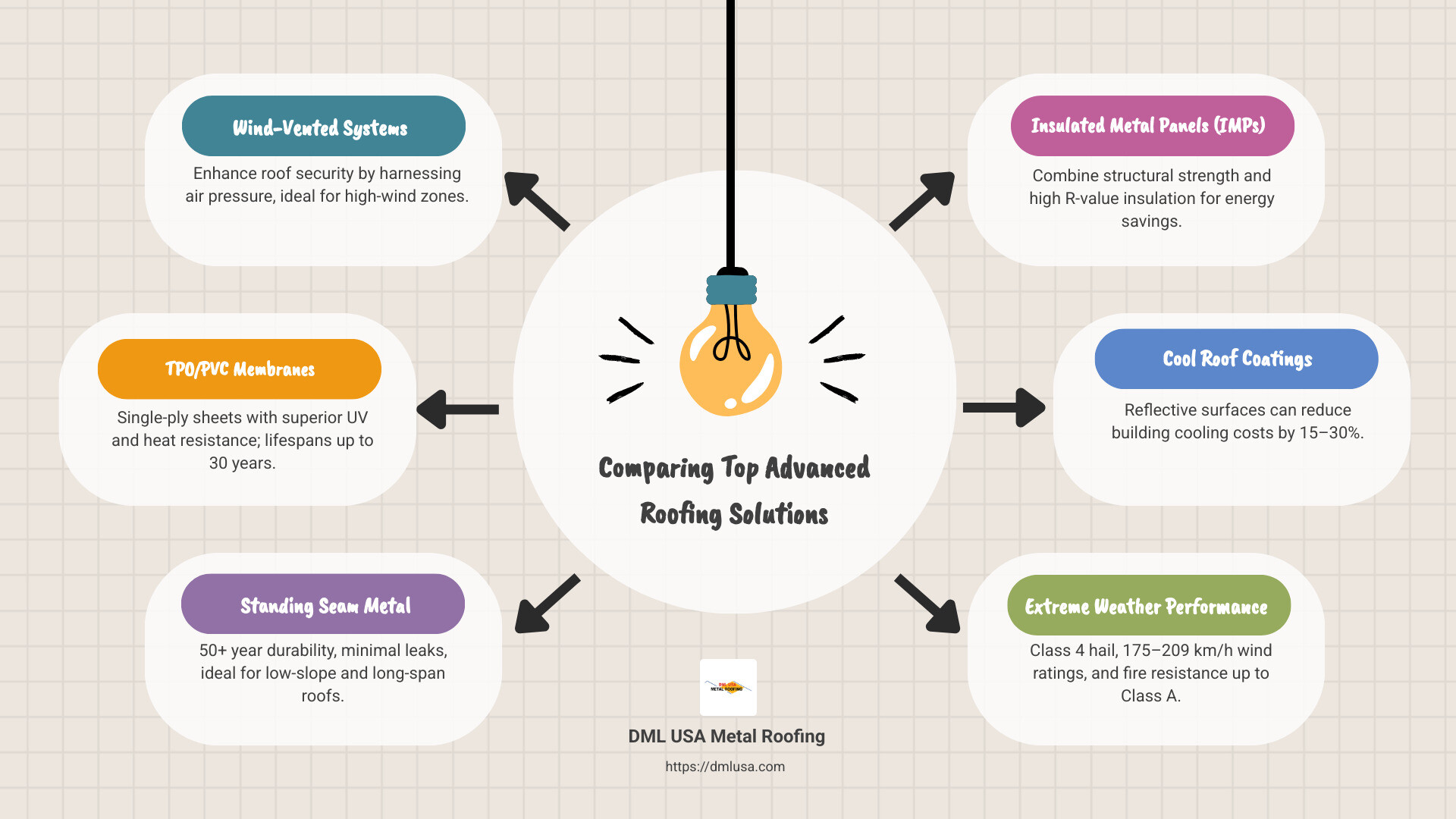

Take wind-vented systems, for example. These clever designs actually harness air pressure during storms to improve roof security – turning a potential threat into an advantage. I’ve seen these systems withstand conditions that would have torn traditional roofing to shreds.

TPO and PVC membranes have become superstars in the commercial world, offering single-ply solutions with exceptional resistance to UV damage and heat. Building owners love them for their clean appearance and impressive performance.

Standing seam metal roofing has always been my personal favorite. With lifespans exceeding 50 years and minimal maintenance requirements, they’re the definition of “install it and forget it.” One contractor recently told me, “The 238T system has been perfect for really long runs on lower slopes, solving problems we’ve struggled with for decades.”

Insulated Metal Panels (IMPs) are another game-changer, combining structural elements with built-in insulation for remarkable energy efficiency. And cool roof coatings can slash cooling costs by 15-30% by simply reflecting sunlight away from the building.

Many of these systems eliminate common failure points like panel endlaps – traditionally the number one source of roof leaks. Others incorporate technology that actively removes moisture or equalizes pressure during high winds.

I’m Adam Kadziola from DML USA Metal Roofing. I’ve dedicated my career to developing and manufacturing advanced roofing solutions that combine lasting quality with maintenance-free design. My experience with high-performance metal roofing systems has given me a front-row seat to this roofing revolution.

Advanced roofing solutions terms at a glance:

– Affordable roofing contractors

– Roofing contractors Chicago

– Learn more about roofing technology on Wikipedia

Advanced Roofing Solutions: Company Snapshot & Service Spectrum

At DML USA Metal Roofing, we’re proud to be pioneers in the advanced roofing revolution. Our Illinois-based operations in Northlake and Chicago have been manufacturing exceptional metal roofing products for over 40 years, earning an A+ BBB rating that reflects our commitment to quality and customer satisfaction.

We’ve watched the roofing landscape transform dramatically over four decades, during which time our team has completed more than 5,000 commercial roofing and re-roofing projects nationwide. Our specialty in metal roofing systems isn’t just about staying current —it’s about leading the industry with solutions that offer superior protection against nature’s harshest elements.

When you work with us, you gain access to a complete spectrum of roofing services. We provide custom residential and commercial roofing custom to homes, retail centers, warehouses, and industrial facilities alike. Whether you need roof replacement, repairs, or a preventative maintenance program to extend your roof’s lifespan, our team delivers solutions built to last.

We’re also there when emergencies strike, offering storm and hail damage restoration services when you need them most. Not sure what condition your roof is in? Our free roof inspections provide professional assessment with zero obligation.

What truly sets our metal roofing apart is its maintenance-free nature and eligibility for energy tax credits. While conventional roofing might need replacement after 15-20 years, our properly installed systems can protect your property for 50+ years —a testament to why Advanced roofing solutions like ours are revolutionizing the industry.

Why Trust “Advanced roofing solutions” for Your Next Project?

In a field crowded with contractors making grand promises, discerning quality from marketing talk can be challenging. The best Advanced roofing solutions providers stand apart through their organizational structure, safety records, and unwavering commitment to excellence.

What makes industry leaders different? It starts with ownership models. Top companies often feature 100% employee ownership, creating environments where everyone has personal stake in your project’s success. As Curt De Boer, a veteran roofing contractor, puts it: “When recommending advanced systems to my customers, I need to know the manufacturer is personally committed and will always stand behind their product.”

The best providers also maintain integrated operations rather than relying heavily on subcontractors. This approach ensures seamless coordination between design, fabrication, installation, and maintenance teams. Additionally, safety excellence matters —industry leaders maintain Experience Modification Rates (EMR) as low as 0.68, significantly below average, reflecting care that extends to every aspect of their work.

Perhaps most importantly, true professionals build their businesses around exceeding expectations, not merely meeting them. This customer-first culture drives everything from material selection to installation practices to follow-up service.

At DML USA Metal Roofing, these principles guide our manufacturing process. We focus on creating only the highest-quality metal roofing systems, designed for decades of performance and backed by comprehensive warranties and ongoing support.

The Areas We Cover & How to Reach Us

DML USA Metal Roofing strategically serves customers throughout Illinois and beyond from our manufacturing facilities in Northlake and Chicago. While we focus on creating exceptional products rather than installation, our advanced metal roofing systems are installed by certified contractors across the Greater Chicago metropolitan area, Northern Illinois, and surrounding Midwest states.

Our reach extends much further, though. Our metal roofing products have found homes on commercial and residential buildings nationwide, protecting everything from small retail establishments to massive industrial complexes. We’ve also developed partnerships with nationwide cooperatives to ensure our Advanced roofing solutions are available wherever they’re needed.

Getting started with us couldn’t be easier:

Reach out through our website contact form for prompt assistance, send us an email, visit our showrooms in person, or request material samples to help with your decision-making process. Every inquiry receives personalized attention from our knowledgeable team, who will guide you through selecting the ideal roofing solution for your specific needs and provide a free estimate.

Our commitment to quality, durability, and customer satisfaction makes DML USA Metal Roofing the perfect partner for your next roofing project —whether you’re looking to upgrade a single-family home or protect a commercial complex for decades to come.

Cutting-Edge Roofing Systems & Materials

Remember when roofs were just… roofs? Those days are long gone! The commercial roofing world has undergone an amazing change in recent years. At DML USA Metal Roofing, we’ve had a front-row seat to this evolution, and we’re proud to manufacture metal roofing systems that represent the best of what modern technology has to offer.

Let me walk you through the exciting innovations that are changing the game for building owners everywhere.

Our standing seam metal roofing systems have become the gold standard for durability. With concealed fasteners that eliminate potential leak points and panel heights ranging from 1.5″ to 2.75″, these systems adapt beautifully to various slope requirements. The best part? They can last over 50 years with minimal maintenance.

Charlie Smith, a veteran in the industry, recently told me, “The panels can be manufactured right onto the roof in continuous lengths, and the longest panels that we’ve run at 250′ plus. This eliminates endlaps, which are the single most common area for roof leaks.” That’s the kind of practical innovation that makes a real difference!

For buildings with low slopes, single-ply membranes offer exceptional performance options. TPO membranes provide remarkable UV resistance—up to 2.5 times industry standards. If you’re dealing with industrial chemicals, PVC membranes might be your best bet with their superior chemical resistance. And don’t overlook EPDM, which delivers excellent weather resistance and flexibility in challenging environments.

What excites me most about these systems is how they’re installed. Modern techniques use flame-free, electric welding that creates seams up to 50mm wide with superior strength. It’s like comparing modern surgical techniques to medieval medicine—the precision is just remarkable.

Have you heard about Insulated Metal Panels (IMPs)? They’re revolutionizing building envelope technology by combining structural support with thermal efficiency. With R-values ranging from R-7 to R-42, they provide exceptional thermal performance while reducing labor costs through single-component installation. It’s like getting insulation and roofing in one neat package.

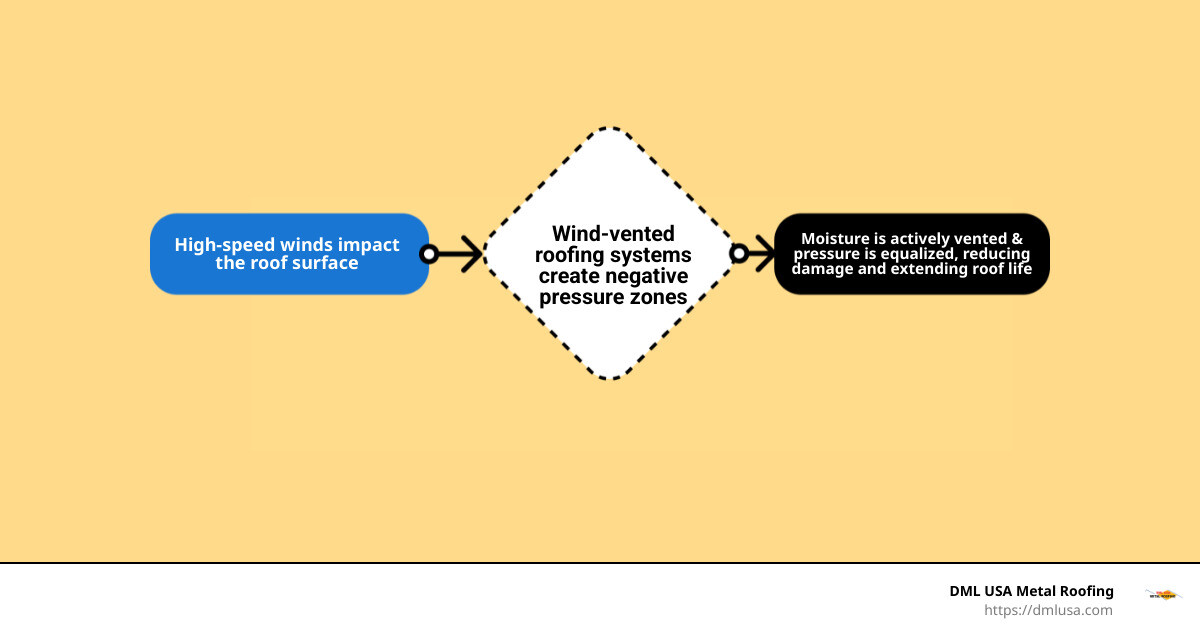

Perhaps the most innovative development I’ve seen in my years in the industry is wind-vented roofing systems. These clever systems actually use the force of wind to improve roof security—talk about turning a problem into a solution! As one contractor shared with me, “We have installed over 10,000,000 square feet of vented roof assemblies. All are still in place and performing after 24 years.” These systems create negative pressure zones that actively remove moisture and equalize pressure during high winds.

| System Type | Lifespan | Wind Resistance | Energy Efficiency | Initial Cost | Lifecycle Cost |

|---|---|---|---|---|---|

| Standing Seam Metal | 50+ years | 140+ mph | High | Higher | Lowest |

| TPO Membrane | 20-30 years | 90-100 mph | High | Moderate | Moderate |

| PVC Membrane | 20-30 years | 90-100 mph | High | Moderate | Moderate |

| Wind-Vented Systems | 30+ years | 175-209 km/h | Moderate | Higher | Low |

| IMPs | 40+ years | 140+ mph | Highest | Higher | Low |

Want to dive deeper into the benefits of metal roofing? Visit our Why Choose Metal Roofing page for more details that might surprise you.

“Advanced roofing solutions” for Extreme Weather Defense

Climate change isn’t just a news headline—it’s changing how we need to protect our buildings. As weather events become more unpredictable and severe, your roof needs to be ready for anything. That’s where advanced roofing solutions really shine.

Our metal roofing systems at DML USA Metal Roofing are built tough for extreme conditions. When it comes to high winds, our systems are rated up to 140+ mph—strong enough to withstand hurricane-force blasts. The secret is in the interlocking panel design that creates a continuous surface, working with specialized clips that allow for thermal movement without compromising strength.

Lynn Price, a roofing contractor who’s seen it all, shared this story: “We just installed two vented roof systems. After installation, both projects were hit by the derecho wind event. Cedar Rapids sustained 45 minutes of 100MPH causing great damage. The advanced roofs survived without any damage while other nearby roofs were blown off the buildings.” Now that’s peace of mind you can count on!

Worried about hail? Our metal roofing achieves Class 4 impact resistance—the highest rating available. This means they can take the hit of 2-inch diameter steel balls dropped from 20 feet without puncturing. Try doing that with traditional roofing!

Fire safety is another area where our metal roofing excels, with Class A fire ratings that provide superior protection. Unlike some roofing materials that can actually feed a fire, metal roofing is non-combustible and helps contain fires rather than spread them.

Perhaps most ingenious is how our advanced roofing solutions handle moisture. Innovative venting technology actively removes trapped water vapor, preventing the condensation issues that plague traditional roofs. It’s like giving your roof the ability to breathe—addressing one of the primary causes of premature failure.

Sustainable & Eco-Friendly Options

Going green isn’t just good for the planet—it’s good for your bottom line too. At DML USA Metal Roofing, sustainability isn’t an afterthought; it’s built into everything we make.

Our metal roofing contains significant recycled content—typically 25-95% depending on the specific product. And unlike traditional roofing materials that end up in landfills after 15-20 years, our metal roofs last 50+ years and are 100% recyclable when they finally do need replacement. It’s the roofing equivalent of the reusable water bottle!

Building a LEED-certified property? Our advanced roofing solutions can help you earn over a dozen LEED® credits. From recycled content to regional materials, heat island reduction to energy performance—metal roofing checks so many boxes for sustainable building certification.

The ULTRA-Cool™ coatings on our metal roofing meet or exceed Energy Star® requirements for solar reflectance. Instead of absorbing heat like traditional dark roofing, these specialized finishes reflect solar radiation, reducing cooling costs by 15-30% in many buildings. It’s like putting your building under a beach umbrella on a hot summer day.

One sustainability expert I spoke with put it perfectly: “Commercial roofing waste from tear-offs is a significant contributor to landfill overload. Advanced systems that can be installed over existing roofs or that last twice as long make a substantial difference in reducing this environmental burden.”

Here’s a pleasant surprise for your accounting department: many of our metal roofing products qualify for federal and state tax incentives designed to encourage energy-efficient building practices. These incentives can significantly offset initial installation costs while promoting long-term environmental benefits.

By choosing DML USA’s sustainable metal roofing, you’re not just making an environmentally responsible choice—you’re making a smart business decision that will pay dividends through reduced energy consumption and maintenance costs for decades to come.

Quality, Safety & Industry Credentials

The true mark of advanced roofing solutions isn’t just about cutting-edge materials or innovative designs. It’s about the commitment to quality standards and safety protocols that ensure your roof performs brilliantly for decades.

At DML USA Metal Roofing, quality isn’t just a buzzword—it’s woven into every step of our manufacturing process. Our metal roofing products don’t just meet industry standards; they’re engineered to exceed them in critical areas like wind uplift resistance, fire safety, impact resistance, weathertightness, and structural performance.

The best roofing contractors know that quality installation is just as important as quality materials. That’s why industry leaders implement thorough quality control measures from start to finish. Before installation begins, they conduct thermal moisture scans to spot hidden issues that could cause problems later. After installation, they perform detailed inspections to verify everything meets their exacting standards.

“Quality isn’t expensive—it’s priceless,” says Adam Kadziola, our production manager. “When you’re talking about protecting a multi-million dollar building, cutting corners on roofing is penny-wise and pound-foolish.”

Some of the most respected manufacturers maintain on-site ASTM E1592 test chambers to validate how their products perform in high winds. This isn’t just about checking a box for certification—it’s about continuous improvement and making sure theoretical performance translates to real-world protection for your building.

Safety records speak volumes about a contractor’s professionalism. The best in the business maintain Experience Modification Rates (EMR) as low as 0.68—well below industry averages. This isn’t just good for their workers; it’s good for your project too. Safe work practices generally correlate with attention to detail and proper installation procedures.

Financial stability matters too. Top commercial roofing contractors carry substantial insurance coverage—often $10 million in general liability—and bonding capacities up to $150 million. This ensures your project is protected, even if something unexpected happens.

Industry credentials serve as important signposts of excellence. When selecting a contractor to install our metal roofing products, we recommend looking for affiliations with respected organizations like the National Roofing Contractors Association (NRCA). Certifications like CertainTeed Master Shingle Applicator and Owens Corning Preferred Contractor status also indicate a commitment to professional standards.

At DML USA Metal Roofing, we’re proud that our manufacturing processes are certified to meet the highest industry standards. This ensures our metal roofing products deliver the performance, durability, and safety that commercial buildings require—today and for decades to come.

Awards & Accolades Demonstrating “Advanced roofing solutions” Excellence

There’s something reassuring about working with a company that’s been recognized by their peers. In advanced roofing solutions, these recognitions aren’t just shiny trophies—they’re valuable indicators of who’s truly delivering excellence.

The most respected companies in roofing regularly receive acknowledgment for their outstanding work. Industry publications like Roofing Contractor Magazine publish annual rankings of top contractors, considering factors like project volume, safety records, employee training programs, and customer satisfaction levels. These aren’t popularity contests; they’re data-driven assessments of who’s performing at the highest levels.

Manufacturer certifications are another important benchmark. These elite designations aren’t handed out like candy—they’re earned through rigorous evaluation and maintained through ongoing performance reviews. When a manufacturer stakes their reputation on a contractor’s work, it speaks volumes about their confidence in that contractor’s abilities.

Local recognition matters too. “Contractor of the Year” and similar honors at the community level reflect a company’s standing where it matters most—with the customers and communities they serve every day. These awards often incorporate direct customer feedback alongside technical excellence.

“We’re particularly proud when our metal roofing products are installed by award-winning contractors,” says Charlie, our customer relations manager. “It means our commitment to manufacturing excellence is being matched by installation excellence—and that’s the perfect combination for building owners.”

Safety recognition is especially meaningful in the roofing industry. When industry associations and insurance providers acknowledge a contractor’s exceptional safety record, it reflects their commitment to doing things the right way, every time.

At DML USA Metal Roofing, we’re delighted that our metal roofing products are installed by many award-winning contractors across the country. Their recognition reinforces what we already know—that quality materials installed by quality contractors create roofing solutions that truly stand the test of time.

When you’re evaluating potential roofing partners, pay attention to these recognitions. They’re valuable clues about who’s truly committed to excellence in the competitive advanced roofing solutions marketplace.

Customer Journey: From Inspection to Lifetime Warranty

Starting on a new roofing project might seem overwhelming at first, but understanding what to expect makes all the difference. When you work with quality metal roofing products like those we manufacture at DML USA Metal Roofing, your journey follows a thoughtful, customer-focused path from start to finish.

Initial Assessment and Consultation

It all begins with a thorough roof inspection. Most reputable contractors offer this service at no cost because they understand its value in building trust and creating the right solution for your needs.

During this initial visit, a roofing professional will climb up to examine your current roof’s condition, often using advanced technology like thermal moisture scans to detect hidden issues that aren’t visible to the naked eye. They’ll also evaluate your building’s structural components and discuss how you use your space to understand any specific performance requirements.

“The inspection is really the foundation of everything that follows,” explains one contractor who installs our products. “We need to understand not just what’s wrong today, but what the building needs for the next several decades.”

This comprehensive assessment creates the roadmap for your custom roofing solution, ensuring nothing gets overlooked.

Detailed Proposal and Material Selection

Based on what they find during inspection, you’ll receive a detailed proposal outlining recommended system options with clear explanations of benefits and limitations. The best contractors take time to walk you through material specifications, project timelines, warranty information, and investment details.

This is your opportunity to explore the various metal roofing options we offer at DML USA, from different standing seam profiles to finishes and accessories. You might be surprised by the variety available – modern metal roofing comes in multiple colors and styles to complement any architectural design.

The proposal stage shouldn’t feel rushed. Take your time asking questions and understanding the long-term value analysis that shows why advanced roofing solutions often deliver better returns despite higher initial investments.

Pre-Installation Planning

Once you’ve selected your preferred roofing solution, the behind-the-scenes work begins. This critical phase includes ordering materials, scheduling delivery, acquiring necessary permits, and verifying code compliance.

The project team will be assigned and coordinated, with careful planning to minimize disruption to your building operations. For commercial properties, this might mean scheduling work during off-hours or developing strategies to maintain business continuity throughout the installation.

Good planning at this stage prevents headaches later and ensures your new roof installation proceeds smoothly.

Installation Process

Quality installation is absolutely essential to the performance of advanced roofing solutions. The process typically begins with site preparation and safety setup, creating a secure environment for both workers and building occupants.

If required, the existing roofing will be removed, though in some cases, our metal roofing systems can be installed over existing materials, saving time and reducing landfill waste. The deck will be inspected and repaired as needed before underlayment is installed for additional protection.

The metal panels are then installed following our precise manufacturer specifications, with careful attention to flashing, trim, and accessory installation. Throughout the process, daily cleanup maintains site safety and appearance.

“The installation is where craftsmanship really shows,” notes one experienced contractor. “A great metal roof installed poorly won’t perform to its potential. That’s why we only recommend certified installers who understand the technical requirements of our systems.”

Quality Control and Project Completion

Before considering the project complete, reputable contractors conduct a comprehensive inspection of all installed components. This often includes water testing of critical areas, final cleanup, and removal of all project-related debris.

You’ll typically participate in a walkthrough with the contractor to review the completed work and address any questions or concerns. This is also when warranty registration and documentation are finalized, ensuring your investment is properly protected.

The best contractors take pride in leaving your property cleaner than they found it, with nothing but a beautiful new roof to show they were ever there.

Long-Term Care and Warranty Support

Your relationship with quality roofing contractors continues long after installation day. Scheduled maintenance inspections help ensure ongoing performance, while warranty support provides peace of mind for the duration of coverage.

Good contractors document all service and maintenance for warranty compliance and offer guidance on proper roof care to maximize your system’s lifespan. With our metal roofing systems, this maintenance is typically minimal compared to traditional roofing materials – one of the many benefits that make them such a popular choice.

For more information about our products and how they integrate into this process, visit our product information page.

Insurance Claims & Financing Made Simple

Storm damage often leads to unexpected roofing expenses, and navigating insurance claims can feel like a full-time job. Similarly, financing a new commercial roof represents a significant investment decision that requires careful consideration.

The best providers of advanced roofing solutions offer specialized support to make both processes more manageable. They serve as your advocate throughout the insurance claim process, providing thorough documentation of all storm-related damage, assistance with claim filing, and coordination with insurance adjusters.

“They took care of everything with the insurance company,” shared one relieved customer. “What could have been a nightmare process was actually quite smooth.”

To make quality roofing more accessible, top contractors offer various financing approaches, including in-house financing with terms from 12 to 24 months, no credit check options for qualified commercial property owners, and budget-friendly payment scheduling that accommodates your cash flow considerations.

At DML USA Metal Roofing, we work with contractors who can help building owners steer both insurance and financing considerations, ensuring they can access our high-quality metal roofing products regardless of their immediate financial situation.

Post-Project Care & Long-Term Maintenance

The true value of advanced roofing solutions becomes apparent in the decades following installation. With proper care, premium systems like our metal roofing can deliver exceptional longevity and performance.

Leading roofing contractors offer structured maintenance programs that typically include annual inspections to catch minor issues before they become major problems. They’ll remove debris from roof surfaces and drainage systems, inspect sealants and fasteners, and provide documentation to maintain warranty compliance.

Even the most durable roofing systems may occasionally need emergency attention following extreme weather events. That’s why top providers offer 24/7 emergency response for leak containment and temporary repairs, with priority scheduling for permanent solutions.

For commercial building owners with multiple properties, sophisticated roof asset management services help track warranty information, budget for future replacements, and prioritize repairs to maximize return on investment.

At DML USA Metal Roofing, we design our systems for minimal maintenance requirements, but we recognize that even the most durable materials benefit from regular professional attention. Our products are engineered to facilitate easy inspection and simplified maintenance, contributing to their exceptional long-term value proposition and your peace of mind.

Innovation & Future Trends in Commercial Roofing

The commercial roofing world is constantly evolving, with exciting innovations that are changing how we protect our buildings. At DML USA Metal Roofing, we’re passionate about staying at the cutting edge of these developments to bring you the most advanced solutions possible.

Wind-Smart Systems and Pressure-Equalized Design

One of the most remarkable breakthroughs in recent years has been the development of wind-vented roofing systems. These ingenious designs work with nature rather than against it, using the very forces that typically damage roofs to instead strengthen them.

“We have installed over 10,000,000 square feet of vented roof assemblies. All are still in place and performing after 24 years,” a seasoned industry expert told us recently.

What makes these advanced roofing solutions so effective is their ability to create negative pressure zones that actively work for your building. They pull moisture out from beneath the roofing membrane, equalize pressure during high winds (preventing that balloon effect that can tear roofs away), and address the root causes of roof failure before they become problems.

On-Site Manufacturing Technologies

The days of prefabricated metal panels with numerous seams are quickly becoming history. Today’s on-site roll forming equipment has revolutionized how we install metal roofing systems.

Charlie Smith, who’s been in the industry for decades, explains it perfectly: “The panels can be manufactured right onto the roof in continuous lengths, with the longest panels running 250′ plus. This eliminates endlaps, which are the single most common area for roof leaks.”

This technology allows us to create continuous panels that flow uninterrupted over your building, dramatically reducing potential leak points. It also means custom-length panels that minimize waste and improve the overall appearance of your roof. Even curved architectural designs are now possible with field-formed panels that follow the contours of your building perfectly.

Precision Installation Technologies

The tools and techniques used to install modern roofing have become incredibly sophisticated. Advanced roofing solutions now benefit from robotic seam welding for single-ply membranes, ensuring every inch of your roof receives the same high-quality seal.

Electric welding tools have replaced many flame-based methods, improving both safety and quality. Meanwhile, computer-controlled fastening systems ensure that every screw and clip is installed with precisely the right amount of torque and in exactly the right pattern to maximize wind resistance.

These precision techniques mean today’s roofs perform better and last longer than ever before.

Digital Roof Management

Technology isn’t just changing how we install roofs—it’s changing how we monitor and maintain them too.

Drone-based inspections now allow us to thoroughly document roof conditions without putting anyone at risk. These flying cameras capture high-resolution images that reveal problems invisible from the ground.

Infrared scanning technology can detect moisture that’s penetrated beneath the surface long before it causes visible damage inside your building. Even more impressive, AI-powered systems can analyze these images to spot potential trouble spots that might be missed by the human eye.

Some building owners are even creating “digital twins” of their roofs—virtual models that track conditions over time and help predict when maintenance will be needed.

Integrated Solar Solutions

The marriage between roofing and renewable energy is growing stronger every year. Today’s advanced roofing solutions often incorporate solar capabilities right from the start.

Building-integrated photovoltaics are replacing traditional roofing materials with elements that generate electricity while still protecting your building. Low-profile mounting systems designed specifically for metal roofing allow solar panels to be added without compromising water-tightness.

Some of the most exciting developments combine insulation and solar solutions to maximize both energy efficiency and generation capacity. Your roof becomes not just protection, but an active part of your building’s energy strategy.

Smart Roof Monitoring

Perhaps the most futuristic trend is the emergence of “smart” roofing systems that constantly monitor their own condition.

Moisture detection sensors can now alert building owners the moment water penetrates a roofing assembly—often before any damage occurs. Strain gauges monitor structural loading during heavy snow or high winds, while temperature sensors identify areas where heat is escaping or entering the building.

All this data feeds into predictive analytics systems that can forecast maintenance needs before problems develop. It’s like having a roofing expert constantly checking your building, 24 hours a day, 365 days a year.

At DML USA Metal Roofing, we’re constantly evaluating these innovations to incorporate the most valuable advancements into our metal roofing systems. Our commitment to staying at the forefront of technology ensures that when you choose our products, you’re getting the best that modern roofing science has to offer.

Frequently Asked Questions about Advanced Roofing Solutions

What roofing systems do you specialize in?

At DML USA Metal Roofing, we’re passionate about creating the best metal roofing systems on the market. When people ask what makes our products special, I love sharing how our advanced roofing solutions combine beauty, durability, and energy efficiency in ways traditional roofing simply can’t match.

Our manufacturing focus centers on four main product categories that homeowners and businesses love. Our standing seam metal roofing features hidden fasteners that eliminate leak points while creating clean, modern sight lines. For those who prefer a more traditional look, our metal shingles and tiles deliver the classic aesthetics people want with the strength only metal can provide.

Many customers are drawn to our stone-coated steel roofing options, which brilliantly mimic the appearance of conventional materials while offering metal’s superior protection. And for commercial applications, our structural and architectural panels provide the perfect balance of form and function.

What truly separates our products from the competition is their virtually maintenance-free nature. While asphalt shingles deteriorate year after year, our metal roofing stands strong for over 50 years when properly installed. They shrug off fire, high winds, and hail impacts that would devastate conventional roofing. Plus, their reflective properties can significantly lower your cooling bills during hot summer months, and many qualify for valuable energy tax credits.

Do you help with storm-damage insurance claims?

While our focus at DML USA Metal Roofing is crafting exceptional metal roofing products rather than installation, we partner with contractors who excel at guiding customers through the often-confusing insurance claim process.

After a storm damages your roof, these professional installers typically begin by thoroughly documenting every bit of damage with detailed photos and measurements. They’ll help you file the initial claim properly, ensuring nothing gets overlooked. When the insurance adjuster visits, your contractor will be there to walk through the findings together, making sure all damage is properly acknowledged.

One customer recently told me, “I was dreading dealing with insurance after the hailstorm, but my contractor handled everything. They even found additional damage during repairs and helped me file a supplemental claim. I barely had to lift a finger!”

It’s worth mentioning that one of the greatest benefits of choosing our metal roofing is how rarely you’ll need to make storm damage claims in the future. While traditional roofing materials often surrender to severe weather, our advanced roofing solutions stand strong through conditions that would destroy lesser products.

What warranties and financing options are available?

We stand firmly behind everything we make at DML USA Metal Roofing. Our comprehensive warranties reflect the confidence we have in our products’ long-term performance.

Depending on which product line you choose, your warranty typically covers material integrity against manufacturing defects, finish performance protecting against peeling or fading, and weather-tightness when installed by certified professionals. Most of our warranties extend 30 to 50 years – about twice the coverage of traditional roofing materials.

As Tom from Chicago told us after installing our standing seam system: “The warranty alone made the decision easy. Knowing I’ll never have to worry about my roof again during my lifetime gave me incredible peace of mind.”

While we focus on manufacturing rather than financing, the contractors who install our products typically offer several payment options to make our advanced roofing solutions accessible to more homeowners and businesses. These often include traditional financing through banking partnerships, in-house payment plans spanning 12-24 months, and sometimes no-credit-check options for qualified property owners.

For storm damage situations, many contractors offer deferred payment arrangements aligned with insurance disbursements, eliminating out-of-pocket expenses while waiting for claim approval.

Don’t forget that many of our metal roofing products qualify for federal and state tax incentives designed to encourage energy-efficient building practices. These incentives can significantly reduce your overall investment, making premium metal roofing even more affordable in the long run.

Conclusion

The revolution in advanced roofing solutions has transformed what building owners can expect from their roofing systems. Today’s high-performance roofing isn’t just a necessary expense—it’s a strategic investment in your building’s performance, sustainability, and long-term value.

At DML USA Metal Roofing, we’re proud to be at the forefront of this revolution. As an Illinois-based manufacturer, we’ve built our reputation on creating high-quality, affordable metal roofing products that stand the test of time. Our commitment to durability, energy efficiency, and superior protection against fire, wind, and impact has made us a trusted partner for projects across the Midwest and beyond.

When you choose our advanced roofing solutions, you’re investing in exceptional durability with lifespans exceeding 50 years—often outlasting the building itself. You’re also getting maintenance-free performance that dramatically reduces lifetime ownership costs, giving you peace of mind for decades to come.

The superior weather resistance of our metal roofing systems means your building stays protected even in the most extreme conditions. Meanwhile, their energy efficiency translates to real, ongoing savings on your utility bills. Our customers regularly report cooling cost reductions of 15-30% after installing our reflective metal roofing systems.

We’re also committed to environmental sustainability. Our products contain significant recycled content and are 100% recyclable at the end of their long service life. This focus on sustainability isn’t just good for the planet—it can help your building earn valuable LEED credits and qualify for tax incentives.

Perhaps best of all, our metal roofing offers aesthetic versatility that complements any architectural style. Whether you’re looking for the clean, modern lines of standing seam panels or the traditional appearance of metal shingles, we have options to improve your building’s appearance.

As we’ve explored throughout this guide, commercial roofing technology continues to evolve rapidly. From wind-vented systems that harness aerodynamic principles to digital monitoring technologies that predict maintenance needs, the future of roofing is increasingly sophisticated and performance-driven.

When you’re ready to experience the benefits of truly advanced roofing solutions, we invite you to explore our full product line and find how DML USA Metal Roofing can transform your next project.

Ready to take the next step? Contact us today through our website for a free consultation and find out why more building owners are choosing metal roofing for their advanced roofing needs. Our team of experts is standing by to answer your questions and help you select the perfect solution for your specific requirements.