astm d3161 class f shingles: 7 Powerful Benefits in 2025

What Homeowners Need to Know About ASTM D3161 Class F Shingles

ASTM D3161 Class F shingles are asphalt or similar roofing shingles that have passed the highest wind-resistance test under the ASTM D3161 standard, withstanding fan-induced winds of up to 110 mph for two hours. Here’s what this means in plain English:

| Feature | ASTM D3161 Class F Shingles |

|---|---|

| Wind Resistance | 110 mph (highest ASTM D3161 rating) |

| Test Method | Fan-induced wind, 2 hours at rated speed |

| Code Compliance | Accepted for all wind zones (incl. Florida) |

| Labeling | “ASTM D3161 Class F” must be on shingle wrapper |

| Use Case | Ideal for homes in hurricane or high-wind areas |

Quick answer:

– astm d3161 class f shingles = roofing shingles tested to withstand 110 mph winds, certified for use in the highest wind zones, and required or recommended by building codes in many storm-prone regions.

Storm damage is one of the top causes of property loss for homeowners. That’s why wind-resistant shingle standards like ASTM D3161 aren’t just technical jargon—they can make the difference between a roof that weathers the storm and one that ends up scattered across your yard.

“A quality shingle roof should be able to protect your home against extreme weather conditions.”

As the owner of DML USA Metal Roofing and a manufacturer with years of experience helping homeowners choose the right protection, I’ve seen how astm d3161 class f shingles can preserve your investment and bring peace of mind—even in hurricane country.

Astm d3161 class f shingles terms explained:

– 3 tab shingles wind resistance

– hurricane proof roofs

– roof wind resistance

Why Wind Standards Matter

In the Midwest, particularly here in Illinois where we’re based, we understand the power of wind. A standard thunderstorm can produce gusts of 50-60 mph, while severe systems can reach 100 mph or more. When Hurricane Ida’s remnants swept through our region in 2021, many homeowners learned the hard way that not all roofing is created equal.

Wind damage to roofs accounts for billions in insurance claims annually. According to industry data, wind-related claims are the most common type of homeowner insurance claim, with an average cost of $10,000 per incident. But beyond the immediate damage costs, there are other compelling reasons why wind standards matter:

- Code compliance: Many jurisdictions now require wind-rated shingles based on local wind speed maps

- Insurance savings: Many carriers offer discounts for wind-resistant roofing

- Roof longevity: Even moderate winds can gradually loosen standard shingles over time

- Peace of mind: Knowing your roof is rated for your area’s wind conditions is invaluable

As one of our Chicago customers told us after upgrading to Class F rated materials: “I used to lie awake during every storm. Now I sleep through them.”

Decoding ASTM Standards for Roofing Wind Resistance

Let me guide you through the wind resistance ratings that might save your roof during the next big storm. As someone who’s weathered many Midwest storms, I know these standards aren’t just technical mumbo-jumbo—they’re your home’s first line of defense.

ASTM International (formerly known as the American Society for Testing and Materials) creates the standards that determine if your shingles will stay put when the wind comes howling. For roofing, two standards really matter:

- ASTM D3161: Uses fans to simulate real-world wind conditions

- ASTM D7158: Measures how much uplift force shingles can resist

Both appear in building codes across America, but they test different aspects of wind performance. Let’s break them down in plain English.

ASTM D3161 in a Nutshell

This granddaddy of wind tests has been around since 1972, with roots going back to the 1950s. It’s refreshingly straightforward—big industrial fans blow air at shingles to see if they stay put.

Picture this: roofing technicians install shingle samples exactly as they would on your home, place them on a gentle 2:12 slope (the minimum for most roofs), and then blast them with giant fans for two hours straight. After this wind marathon, inspectors check for any lifting, tearing, or other damage.

Based on how well they hold up, shingles earn one of three wind resistance badges:

Class A: Holds tight at 60 mph (good for calm areas)

Class D: Stays put at 90 mph (suitable for most regions)

Class F: Withstands a howling 110 mph (best for hurricane zones)

The test started with just Class A, but as shingle technology improved and severe weather became more common, they added Classes D and F to meet the needs of homeowners in windier regions.

“The original D3161 methodology was developed by the National Bureau of Standards in the 1950s. Revisions added 90 mph and 110 mph classifications beyond the original 60 mph test.”

ASTM D7158 Lifts the Bar

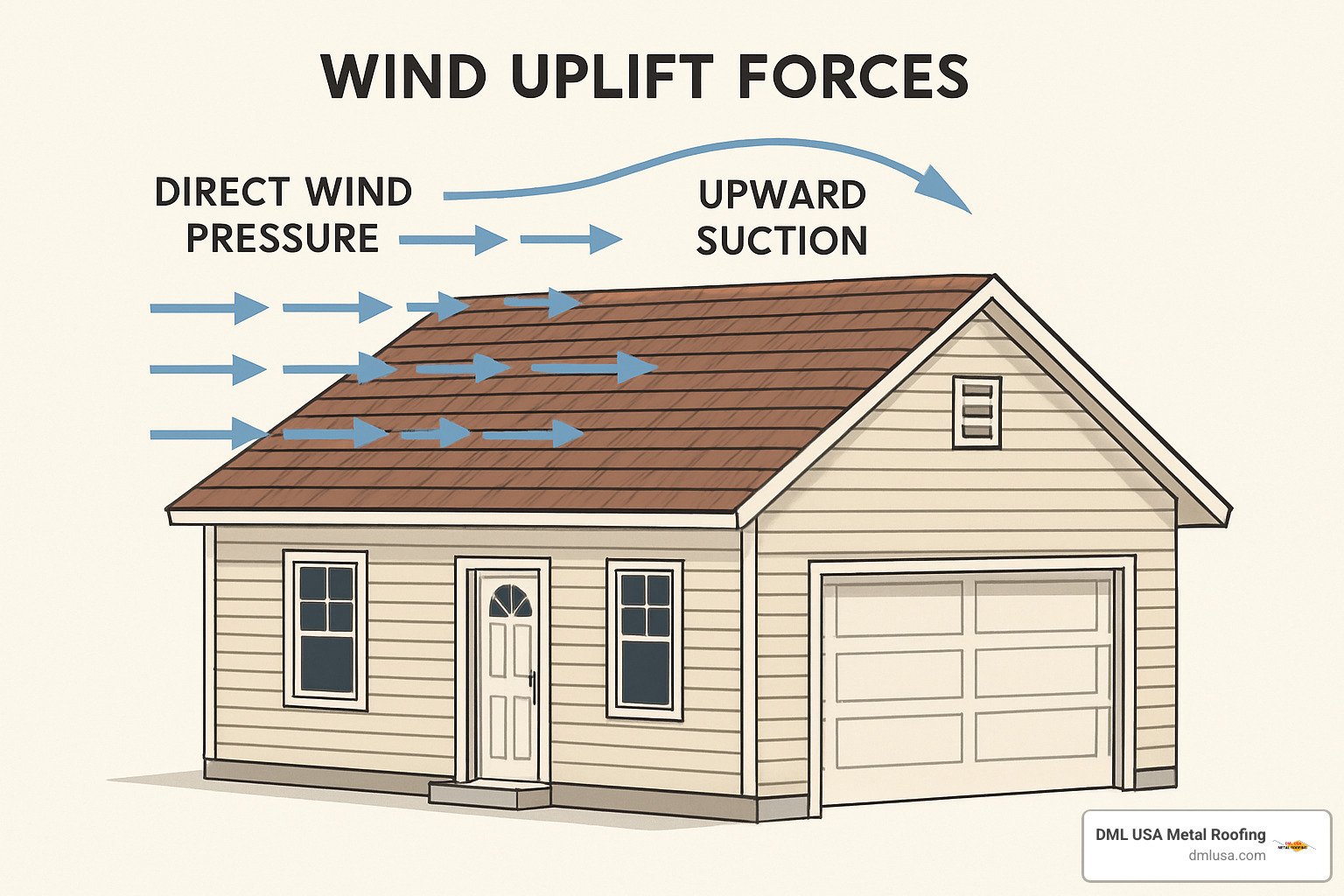

While D3161 simulates direct wind, the newer ASTM D7158 (introduced in 2005) focuses on something equally important—uplift resistance. Think about how wind creates a vacuum effect as it passes over your roof. This test measures how well shingles resist getting sucked upward.

The D7158 classifications might look confusing at first:

Class D: Resists winds up to 115 mph (Vasd) or 150 mph (Vult)

Class G: Handles winds up to 120 mph (Vasd) or 195 mph (Vult)

Class H: Withstands winds up to 150 mph (Vasd) or 190 mph (Vult)

You’re probably wondering about those “Vasd” and “Vult” terms. They represent two different ways building codes measure wind speed:

Vasd stands for “Velocity allowable stress design”—the older method

Vult means “Velocity ultimate”—the newer method that’s typically 1.3 times higher than Vasd

This dual system exists because building codes are in transition. The 2018 International Building Code accepts either method, which can create some head-scratching moments when comparing products.

ASTM D7158 is based on sophisticated wind-load calculations from ASCE 7 (American Society of Civil Engineers). It considers real-world factors like:

Building height (up to 60 feet)

Exposure category (is your home on a hill or surrounded by other buildings?)

Risk category (how critical is your building’s function?)

One important note: D7158 only applies to self-sealing asphalt shingles—those with adhesive strips that activate with sun exposure. For other roofing types, including most metal roofing systems like ours at DML USA, ASTM D3161 remains the go-to test.

Want to dig deeper into the science? The National Roofing Contractors Association offers excellent research on how these standards translate to real-world performance.

ASTM D3161 Class F Shingles: What the Label Really Means

When you see “ASTM D3161 Class F” on a bundle of shingles, it means those shingles have passed the most rigorous level of the fan-induced wind resistance test. But what does that really tell you about how they’ll perform on your roof?

The Class F designation means the shingles remained intact during a continuous 110 mph wind test for two hours. This is significant because:

- Most severe thunderstorms produce gusts between 58-90 mph

- Category 1 hurricanes range from 74-95 mph

- Category 2 hurricanes range from 96-110 mph

So astm d3161 class f shingles are designed to withstand winds up to Category 2 hurricane strength. However, it’s important to understand that this doesn’t guarantee your shingles will never blow off in winds below 110 mph. Why? Because the test is conducted in controlled laboratory conditions that don’t perfectly replicate real-world scenarios.

The Florida Building Code and many other coastal building codes recognize this value, which is why astm d3161 class f shingles are acceptable for use in all wind speed zones, including hurricane-prone regions.

For verification purposes, manufacturers must label their packaging to indicate compliance. Look for language like “ASTM D3161 Class F” or “Tested in accordance with ASTM D3161 Class F” on the wrapper.

How the ASTM D3161 Class F Shingles Test Is Performed

Understanding the testing process helps explain what this rating actually means for your home. Here’s a more detailed look at how astm d3161 class f shingles earn their rating:

Sample preparation: Multiple shingle specimens are applied to standard test panels exactly according to manufacturer’s instructions.

Conditioning: The samples are conditioned at room temperature (73.4°F ± 3.6°F) for at least 4 hours before testing.

Test setup: The panel is mounted at a 2:12 slope (the minimum slope for most steep-slope roofing products).

Wind exposure: Industrial fans generate a consistent 110 mph wind stream across the shingle surface for two continuous hours.

Evaluation: Throughout and after the test, inspectors check for:

- Tab lifting or disengagement

- Sealant failure

- Damage to the shingle surface

- Fastener pullout

To pass and earn the Class F designation, the shingles must show no evidence of tab lifting or damage after the full two-hour exposure.

“ASTM D3161 subjects shingles to wind velocities of 60, 90, or 110 mph for two hours; Class F is the highest rating, passing at 110 mph.”

It’s worth noting that the test examines more than just the shingle material itself—it’s testing the entire system, including:

- The sealant strip performance

- The shingle’s structural integrity

- The fastening method’s effectiveness

Wind Speeds & Field Performance of ASTM D3161 Class F Shingles

While laboratory tests provide standardized comparisons, real-world performance is what ultimately matters. How do astm d3161 class f shingles actually hold up in the field?

According to industry research, shingles that have passed the ASTM D3161 Class F test have generally performed well in high-wind regions. As noted in Professional Roofing magazine, “Most steep slope roofing products that have demonstrated wind resistance by ASTM D3161 Class F testing have also performed well in use.”

However, real-world performance depends on several factors beyond the shingle rating:

- Installation quality: Proper nailing pattern and technique are crucial

- Roof geometry: Complex roof designs with multiple slopes create more wind pressure points

- Exposure: A home on a hilltop faces different wind patterns than one in a sheltered valley

- Maintenance: Sealant strips can degrade over time and may need inspection

- Age: Even the best shingles lose some wind resistance as they age

For homeowners in areas with basic wind speeds (Vult) of 110 mph or greater, astm d3161 class f shingles are often required by code. This includes much of Florida, the Gulf Coast, and portions of the Atlantic seaboard.

Class F vs Class D vs Class A—and How They Stack Up to ASTM D7158

If you’re shopping for wind-resistant shingles, you’ll quickly find a confusing alphabet soup of ratings. Let me break this down in simple terms so you can make the right choice for your home.

Think of these wind classes like hurricane categories—the higher the rating, the stronger the wind they can handle. ASTM D3161 Class F shingles represent the top tier in this particular standard, but how do they compare to other options?

| ASTM D3161 Class | Wind Speed Rating | Suitable For |

|---|---|---|

| Class A | 60 mph | Low wind areas |

| Class D | 90 mph | Moderate wind areas |

| Class F | 110 mph | High wind and hurricane-prone areas |

When I talk with homeowners in Illinois, I often explain that Class A might be sufficient for sheltered neighborhoods in calm regions, while Class F is what you want if you live on an exposed hilltop or in areas that see severe thunderstorms. The difference between surviving a storm with minor repairs versus major damage often comes down to this rating.

But here’s where it gets a bit more complicated. There’s another standard called ASTM D7158 that you might see on shingle packaging. These two standards measure different aspects of wind resistance:

| ASTM D3161 | ASTM D7158 | Approximate Equivalent |

|---|---|---|

| Class A (60 mph) | Below Class D | Basic wind protection |

| Class D (90 mph) | Class D (115 mph) | Standard wind protection |

| Class F (110 mph) | Class G (150 mph) | High wind protection |

| N/A | Class H (190 mph) | Extreme wind protection |

Why such different mph ratings? It’s not that one test is “better” than the other—they’re measuring completely different things:

ASTM D3161 uses fans to blow directly at the shingles, simulating wind hitting your roof head-on. This is the fan test we discussed earlier.

ASTM D7158 measures uplift resistance—the suction effect that happens when wind creates negative pressure as it moves over your roof (similar to how airplane wings generate lift).

In the real world, your roof faces both direct wind force and uplift during storms. That’s why premium shingles are often tested and rated under both standards. A shingle with ASTM D3161 Class F and ASTM D7158 Class G ratings provides excellent all-around wind protection for most homes.

Building codes typically accept either standard, though some areas have specific requirements. The Florida Building Code, for instance, references both standards in Table R905.2.6.1, allowing builders to demonstrate compliance through either test.

As a homeowner, the simplest approach is to look for ASTM D3161 Class F shingles at minimum if you live in an area with significant wind concerns. For extreme wind regions, consider products that also carry the ASTM D7158 Class H rating for the ultimate peace of mind.

Specifying & Installing Class F Shingles for Maximum Wind Security

Choosing astm d3161 class f shingles is just the beginning of your wind-resistant roofing journey. As we’ve seen time and again with our customers, even the best materials can fail when not installed properly. Think of it like buying a premium parachute but packing it incorrectly—the quality won’t matter if the execution isn’t right!

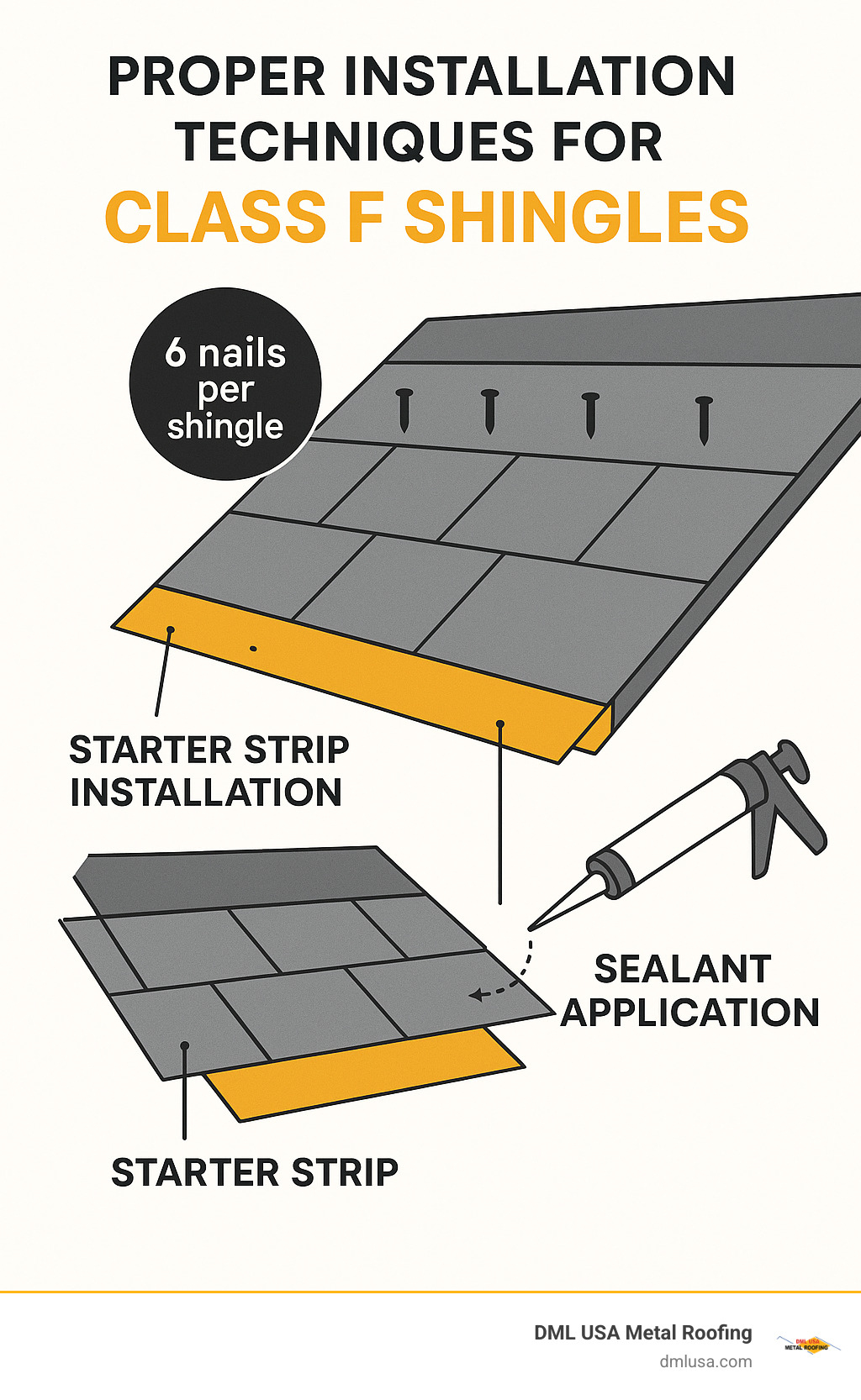

The secret to maximizing your wind protection lies in the details. When we talk with homeowners about proper installation, we emphasize that fastener placement is absolutely critical. Most manufacturer specifications for Class F shingles require 6 nails per shingle instead of the standard 4—those two extra nails make a significant difference when winds start howling around your eaves.

Temperature plays a surprising role too. Those self-sealing strips that keep your shingles locked down? They need heat to activate properly. If you’re getting a roof installed during chilly Illinois fall weather, your contractor might need to manually seal those tabs. I remember one customer in Naperville whose roof was installed in November and never properly sealed—by spring, several shingles had already worked loose.

Starter strips deserve special attention as well. These unsung heroes protect the vulnerable edges of your roof at both eaves and rakes. Without proper starter strip installation, even Class F shingles can catch wind at the edges and begin the “peeling” process that eventually leads to roof failure.

Your roof deck forms the foundation of your entire roofing system. Before installation begins, ensure it’s in good condition with no rot or weak spots. A Class F shingle can’t perform to its rating if it’s nailed to deteriorating plywood!

For truly maximum wind resistance in our Midwestern storms, we recommend these improved installation practices:

“Historically, shingles that passed ASTM D3161 wind tests have performed reliably in service—but only when properly installed.”

When discussing wind resistance with our customers, I often use this analogy: your roof is only as strong as its weakest component. You might have astm d3161 class f shingles rated for 110 mph winds, but if your ridge caps aren’t secured with additional fasteners, that’s where failure will begin.

Verifying Compliance on-site

“How do I know I’m actually getting what I paid for?” This question comes up often, and it’s a smart one to ask. If you’re investing in astm d3161 class f shingles, verification is straightforward but important.

First, always check the wrapper. The rating must be clearly printed on the bundle. I’ve seen cases where homeowners assumed they were getting Class F shingles, only to find the actual bundles delivered were a lower class. Don’t be shy about examining those wrappers before installation begins!

Product documentation should also list the wind rating explicitly. Many quality shingles carry UL certification for wind resistance as additional verification. For peace of mind, take photos of the wrapper labels before they’re discarded.

Most building inspectors consider the wrapper label sufficient evidence of compliance, but it never hurts to save a section of wrapper for your records. Think of it as saving the receipt for an important purchase—which it absolutely is.

When to Choose Metal Instead

While astm d3161 class f shingles provide excellent protection for many homes, sometimes they’re simply not the best option. As a metal roofing manufacturer, I could say “always choose metal,” but that wouldn’t be honest. Instead, let me share when metal truly outshines even the best asphalt:

For homes in extreme wind zones regularly facing winds above 120 mph, metal roofing provides superior protection. We’ve had customers on Lake Michigan’s shoreline who faced sustained winds that would eventually wear down asphalt, no matter the rating.

Coastal salt exposure is particularly hard on asphalt, but metal better resists this corrosive environment. One customer in Michigan City switched to our metal roofing after replacing his asphalt roof twice in 12 years due to salt deterioration.

From a long-term value perspective, metal typically lasts 2-3 times longer than asphalt shingles. When you factor in this longevity, metal often becomes the more economical choice despite the higher upfront cost.

For maximum wind resistance, many of our metal systems at DML USA are rated for winds up to 150 mph—well beyond the 110 mph threshold of ASTM D3161 Class F. For our Chicago-area customers who’ve experienced those terrifying straight-line winds that occasionally tear through our region, this extra margin of safety provides invaluable peace of mind.

Plus, there’s a bonus many homeowners don’t realize: our metal roofing qualifies for energy tax credits that asphalt shingles don’t. When you’re making your decision, Why Choose Metal Roofing isn’t just about wind—it’s about overall performance, longevity, and value.

Codes, Insurance & Common Myths Around Wind Ratings

Let’s talk about how these wind ratings actually matter in the real world of building codes and insurance policies—because understanding this part can save you both headaches and money.

Building Code Requirements

When I visit homeowners across Illinois, many are surprised to learn that wind resistance isn’t just a nice-to-have feature—it’s often legally required. Most local building codes reference either the International Building Code (IBC) or International Residential Code (IRC), which specify minimum wind resistance based on your location’s typical wind patterns.

Florida, with its hurricane experience, sets some of the strictest standards in the country. Their 2020 residential building code spells it out clearly:

“For homes in areas with basic wind speeds up to 100 mph, you can use either ASTM D3161 Class D or Class F shingles. But once you’re in areas with 110-150 mph wind zones, only Class F shingles make the cut.”

The code actually states: “Shingles classified as ASTM D3161 Class F or TAS 107 or ASTM D7158 Class H are acceptable for use at all wind speeds.” This means astm d3161 class f shingles will meet code requirements anywhere in Florida—and similarly in other coastal states with strict wind provisions.

Here in the Midwest, we have our own high-wind challenges. Many counties in “Tornado Alley” have adopted similar requirements, particularly for new construction and roof replacements.

Insurance Considerations

Your insurance company definitely cares about your roof’s wind rating—and they might reward you for choosing wisely.

“We saved about 15% on our homeowner’s policy after upgrading to Class F shingles,” a customer in Naperville told me last year. “It basically offset the extra cost of the premium shingles within three years.”

These insurance discounts typically range from 5-25% depending on your location and carrier. The closer you are to hurricane zones or high-wind areas, the more significant the savings tend to be.

To qualify for these discounts, you’ll generally need to provide:

– Proof of installation (your contractor’s invoice)

– Documentation of the product’s wind rating

– In some cases, an inspection certificate

I’ve even seen situations where insurance carriers in hurricane-prone regions actually require astm d3161 class f shingles as a condition of coverage. Without them, they simply won’t insure the property—or they’ll charge such high premiums that upgrading to Class F becomes the obvious financial choice.

Common Myths About Wind Ratings

After years in the roofing business, I’ve heard plenty of misconceptions about wind-rated shingles. Let me clear up the most common ones:

Myth 1: A 110 mph rating means shingles will stay intact in any 110 mph wind.

The reality is more nuanced. That rating means they passed a controlled laboratory test at that speed. Real-world performance depends heavily on installation quality, your roof’s design, and the specific characteristics of the storm (duration, rain, debris, etc.). astm d3161 class f shingles give you excellent protection, but no absolute guarantees.

Myth 2: Wind-rated shingles can withstand tornadoes.

I wish this were true, but even the best astm d3161 class f shingles aren’t designed for direct tornado impacts, which can exceed 200+ mph. For severe tornado protection, you need specialized storm shelters—no roof covering alone will suffice.

Myth 3: All new shingles are automatically wind-resistant.

Not true! Many basic economy shingles only meet Class A standards (60 mph). Always verify the specific rating on the package or documentation.

Myth 4: Wind ratings and impact ratings are the same thing.

These are completely different tests measuring different things. Wind resistance (ASTM D3161) tests how well shingles stay attached in high winds, while impact resistance (UL 2218) measures their ability to withstand hail and falling debris. For complete protection, you need both.

Myth 5: Wind ratings last forever.

Unfortunately, wind resistance can degrade over time as sealant strips age and lose effectiveness. Most manufacturers recommend periodic inspections, especially after the roof’s first decade of service.

As one insurance adjuster told me, “The difference between homes with properly installed Class F shingles and those without is night and day after a major windstorm.” That’s why at DML USA Metal Roofing, we recommend wind-resistant materials for every home we service—even when it’s not strictly required by code.

For those in extreme wind zones or seeking lifetime protection, our metal roofing systems offer even higher wind resistance than astm d3161 class f shingles, with ratings up to 150 mph and proven durability. You can learn more in our detailed report on Scientific research on wind resistance.

Frequently Asked Questions about ASTM D3161 Class F

Do Class F shingles guarantee survival in 110 mph storms?

I get this question all the time at home shows, and I always have to give folks the straight answer: No, there’s no absolute guarantee.

Astm d3161 class f shingles have indeed passed rigorous 110 mph wind tests in controlled laboratory settings, but Mother Nature doesn’t follow laboratory rules. Your roof’s actual performance during a storm depends on several real-world factors that no test can perfectly simulate.

The quality of installation makes an enormous difference – I’ve seen perfectly good Class F shingles fail because someone rushed the nailing pattern. Your roof’s shape matters too; complex rooflines with multiple valleys create more stress points. Even the direction the storm hits from can change how your roof handles those gusts.

That said, don’t be discouraged! Properly installed Class F shingles give your home significantly better protection than non-rated or lower-rated alternatives. Think of it like wearing a seatbelt – it doesn’t guarantee you’ll walk away from every accident, but it dramatically improves your odds.

Can ASTM D7158 replace ASTM D3161 for code approval?

This one gets a bit technical, but the simple answer is: it depends on where you live.

Many local building departments accept either standard, treating them as complementary rather than competing requirements. However, some jurisdictions specifically require one or the other. The 2018 International Building Code and International Residential Code generally allow either standard, with an important exception: non-self-sealing shingles must use the ASTM D3161 classifications since D7158 only applies to self-sealing products.

I always recommend checking with your local building department before making assumptions. I had a customer in coastal Florida who ordered materials based on a contractor’s assurance about code compliance, only to have the inspector flag it during the first site visit. A quick phone call beforehand would have saved everyone time and money.

How do I confirm my roof actually has Class F shingles?

If you’re reading this after your roof is already installed, confirming the exact rating can be tricky unless you were organized enough to save the wrapper labels (and let’s be honest, most of us aren’t!).

Here are your best options:

First, check your garage, basement or attic for any remaining packaging materials. Contractors often leave behind an extra bundle.

Second, reach out to your roofing contractor and request the product specifications. Any reputable roofer should have records of what they installed.

Third, look through your paperwork for manufacturer warranty documentation, which typically lists the wind rating.

As a last resort, some manufacturers can identify their products from clear photos, though this isn’t always reliable.

For new installations, I strongly recommend keeping at least one wrapper label and all product documentation for future reference. I actually tell my customers to take a photo of the wrapper and email it to themselves with the subject line “Roof Materials” – it’s a simple trick that can save headaches years later when you’re filing an insurance claim or selling your home.

Astm d3161 class f shingles should be clearly labeled as such on the packaging – it’s not something manufacturers hide, as it’s a major selling point they want you to know about!

Conclusion

Let’s face it—your roof is your home’s first line of defense against Mother Nature’s fury. Choosing ASTM D3161 Class F shingles isn’t just checking a box on a building code form—it’s about sleeping soundly during that midnight storm when the wind howls around your eaves.

Throughout Illinois and the Chicago area, where we at DML USA Metal Roofing call home, severe weather isn’t the exception—it’s the rule. Those Class F shingles represent the highest level of protection under this particular testing standard, giving your home a fighting chance when those summer thunderstorms roll through.

But remember what we’ve emphasized throughout: even the best-rated shingles need proper installation. It’s like buying a top-of-the-line security system but leaving your front door wide open—the technology only works when it’s implemented correctly.

The good news? Upgrading to wind-resistant roofing often qualifies you for valuable energy credits while potentially lowering your insurance premiums. That’s protection that actually pays you back over time.

For the ultimate peace of mind, though, consider the leap to metal roofing. Our metal systems at DML USA exceed even Class F wind ratings while offering superior protection against fire and impact damage. Plus, they qualify for substantial energy tax credits that standard asphalt products simply can’t match.

The real value of wind-resistant roofing goes beyond the technical specifications. It’s about:

- Protecting your most valuable investment through decades of seasonal storms

- Eliminating those middle-of-the-night worries when the weather turns nasty

- Potentially increasing your home’s resale value with upgraded protection

- Creating a more sustainable, longer-lasting roof system

As one of our customers in Naperville put it: “After upgrading to metal, I actually look forward to storms now—just to prove my roof can take it!”

Whether you ultimately choose high-performance asphalt shingles or make the upgrade to metal, understanding wind ratings helps you make an informed decision that will protect your family and home for years to come.

For more information about our wind-resistant metal roofing options that exceed even the impressive standards of ASTM D3161 Class F shingles, visit our products page or reach out to our team. We’re your neighbors here in Illinois, and we understand exactly what your roof needs to face our local weather challenges.