Protect Your Investment: The Ultimate Guide to Metal Roof Coating Companies

When your metal roof starts showing its age, you don’t necessarily need a complete replacement. That’s where metal roof coating companies come in – these specialists apply protective layers that breathe new life into aging metal roofs, stop those annoying leaks, and can even slash your energy bills.

I’ve seen how the right coating transforms a weathered, tired roof into a watertight, energy-efficient asset. Instead of enduring the headache and expense of tearing everything off, these specialized coatings create a seamless protective membrane that can add 10-20 years to your roof’s life.

Having worked with numerous coating providers at DML USA Metal Roofing, I’ve developed a good sense of what delivers quality results. Quality roof coatings have protected over 500 million square feet of roofing in the past 20+ years. The best fluid-applied systems have earned loyal contractor followings. As one of our long-time contractors puts it: “We’ve been working with premium coating systems since 2012 and have never looked back. Of course, the products are great, but the people and the attitudes… make the difference.”

The best rubber coatings on the market achieve an impressive 87% reflectivity – a game-changer for energy efficiency in hot climates. With over four decades of industry experience, top manufacturers have refined their formulations to perform in challenging environments.

For those seeking trusted performance, premium coating products bring 150+ years of coating expertise to the table. The best reflective coatings can reduce cooling costs by up to 40% – a benefit my customers frequently mention when checking in after installation.

Environmentally-conscious building owners appreciate sustainable solutions with impressive arrays of certifications, while the most durable systems back their epoxy-rubber hybrid formulations with confident 12-year leak-free guarantees.

I’m Adam Kadziola from DML USA Metal Roofing, where I’ve spent years evaluating the best metal roof coating companies for our customers’ roofing systems. We understand that selecting the right coating partner is just as important as choosing the right metal roofing material in the first place.

The roofing industry has its own specialized vocabulary. If you’re exploring your options, you might also want to learn about commercial metal roofing contractors, find a reliable metal roof contractor, or research metal roofing installation companies.

A quality coating system paired with our premium metal roofing creates an unbeatable combination for longevity, performance, and value. In the sections that follow, we’ll dive deeper into how to evaluate coating options and companies to ensure you make the best choice for your specific roofing needs.

What Is Metal Roof Coating & Why It Matters

Metal roof coating isn’t just a fancy paint job—it’s your roof’s suit of armor. These specialized protective systems create a seamless membrane that bonds directly with your metal roof, forming a shield that stands guard against whatever Mother Nature throws its way.

When you invest in a quality metal roof coating, you’re actually getting multiple layers of protection working together:

Rust Prevention becomes your first line of defense. These coatings create an impenetrable barrier that keeps moisture from ever touching your metal surface. Even if your roof already shows signs of corrosion, specialized primers can stop rust in its tracks and prevent it from spreading further.

Waterproof Membrane protection is crucial as your metal roof ages. Those seams that once fit snugly start to separate. Fasteners back out over time. Tiny pinholes develop in metal panels. A proper coating system seals all these vulnerable spots with a continuous, watertight layer that keeps everything dry underneath.

The Cool-Roof Science behind today’s coatings is pretty remarkable. As one contractor, Cassy0110, shared in industry forums: “Properly formulated acrylic coatings can reduce the surface temperature as much as 20 degrees F when exposed to direct sunlight at 85 degrees F.” This isn’t just comfort—it’s cash in your pocket. Sherwin-Williams has found that well-coated metal roofs can slash heating and cooling costs by up to 40%.

Your metal roof is constantly dealing with Thermal Expansion challenges. It expands in heat and contracts in cold—a natural process that puts stress on traditional roofing materials. Premium coatings like those from ArmorGarage offer what they call “99.999% memory retention” with stretch capabilities of 500%, meaning they flex with your metal without cracking or pulling away.

The Lifecycle Extension might be the most impressive benefit. A properly applied coating system can add 10-20 years to your roof’s life—that’s potentially decades more protection without the disruption and expense of a complete tear-off.

Improved Fire & Wind Resistance comes standard with many premium coating systems, giving your building better protection during those severe weather events that seem increasingly common these days.

Here in Illinois, where we experience everything from sweltering 95°F summer days to bone-chilling -10°F winter nights, your roof coating needs exceptional temperature flexibility. At DML USA Metal Roofing, we specifically recommend systems that maintain their protective properties even at temperatures as low as -40°F, ensuring your roof stays protected year-round.

The right coating doesn’t just cover your metal roof—it transforms it into a more resilient, efficient, and long-lasting system that protects everything beneath it.

How to Choose Among Metal Roof Coating Companies

Finding the right metal roof coating company shouldn’t feel like searching for a needle in a haystack. After years of helping Illinois building owners protect their metal roofs, we’ve learned what truly matters when making this important decision.

Decision Checklist for Metal Roof Coating Companies

Think of choosing a coating company as similar to selecting a doctor for your roof. You want someone with the right expertise who uses quality materials and stands behind their work.

The first thing to check is substrate compatibility – not all coatings work on all metal types. A quality provider will ask specific questions about your existing roof (is it galvanized? aluminum? painted?) before recommending solutions.

Warranty coverage matters tremendously, but look beyond just the number of years. Does it cover labor costs for repairs? Are there exclusions for ponding water? The fine print makes all the difference.

Working with certified applicators ensures your coating is applied correctly. The best companies maintain networks of approved contractors nationwide – this certification means your roof gets installed by teams who know exactly what they’re doing.

Don’t overlook reflectivity ratings when comparing options. Higher Solar Reflectance Index (SRI) values translate directly to energy savings. Your wallet will thank you during those hot Chicago summers when your cooling bills arrive.

We’ve found that company longevity is a reliable indicator of quality. Manufacturers who’ve been around for decades have refined their formulations through real-world testing – something no laboratory can fully replicate.

For more detailed guidance custom to your specific roofing situation, visit our resources page where we provide in-depth guides and case studies from projects throughout Illinois.

Performance Metrics Every Buyer Should Compare

When you’re investing in protecting your building, the technical specifications matter. Here’s what to focus on:

Durability is best measured through accelerated weathering tests. Look for products that have undergone ASTM 9000 hour testing – this simulates years of real-world exposure and separates truly durable coatings from pretenders.

Tensile strength and elongation work together to determine how well a coating handles the constant expansion and contraction of metal roofing. Premium products offer 500% elongation, meaning they can stretch to five times their original size without failing – crucial during extreme temperature swings.

If your roof has any low spots where water might collect, pay special attention to ponding water tolerance. Silicone coatings generally excel here, while many acrylics will degrade when exposed to standing water for extended periods.

For those of us in the Midwest, hail impact resistance isn’t optional. A coating that cracks or separates after a summer storm leaves your roof vulnerable precisely when you need protection most.

As roof consultants with decades of experience note, finding a coating with superior “adhesion, tensile and tear strength, durability, and repairability” should be your goal. When industry experts with decades of experience single out specific performance characteristics, it’s worth paying attention.

Warranties & Service Programs Offered by Metal Roof Coating Companies

Not all warranties are created equal. The best metal roof coating companies offer comprehensive protection that gives you true peace of mind.

A genuine “No Dollar Limit” (NDL) warranty covers both materials and labor for repairs – this is significantly more valuable than materials-only coverage that leaves you footing the bill for installation costs if something goes wrong.

Some forward-thinking companies offer renewable warranty options through scheduled recoating. This approach can extend your roof’s protection from 5 to 20 years without the disruption and expense of a full tear-off.

If you’re planning to sell your building during the warranty period, make sure to ask about transferable warranty clauses. This feature adds tangible value to your property and can be a strong selling point for potential buyers.

Regular inspection schedules are actually a benefit, not a burden. These professional evaluations catch small issues before they become expensive problems – think of them as wellness checks for your roof.

The best coating manufacturers have confidently warrantied over 500 million square feet of commercial roofing across the United States. That level of commitment speaks volumes about their faith in their products’ performance.

Training & Support Most Metal Roof Coating Companies Provide

The support you receive before, during, and after installation makes a tremendous difference in your overall experience.

The best companies offer on-roof demonstrations where they’ll apply their product to a section of your actual roof. This shows you exactly how it performs on your specific building – much more valuable than glossy brochures or generic samples.

Contractor certification programs ensure consistent application quality. Leading manufacturers invest heavily in their training courses because they understand that even the best coating will fail if improperly applied.

Comprehensive specification libraries with detailed technical data sheets and application guides should be readily available. This transparency helps you understand exactly what you’re getting.

Perhaps most importantly, field technical support during critical phases of application can prevent costly mistakes. Having manufacturer representatives on-site during installation provides an extra layer of quality assurance.

As one of our contractors notes after years of experience with quality coating systems: “The products are outstanding and the service is topnotch.” This combination of quality materials and exceptional support is what truly separates the best coating companies from the rest.

For more information about roof coatings and their benefits, you can visit the Metal Construction Association’s website for technical resources and industry standards.

5 Main Types of Metal Roof Coatings Compared

When you’re researching metal roof coating companies, understanding the different types of coatings is like learning the difference between paint finishes for your home – each has its own special purpose. Let me walk you through the main options so you can make the best choice for your building.

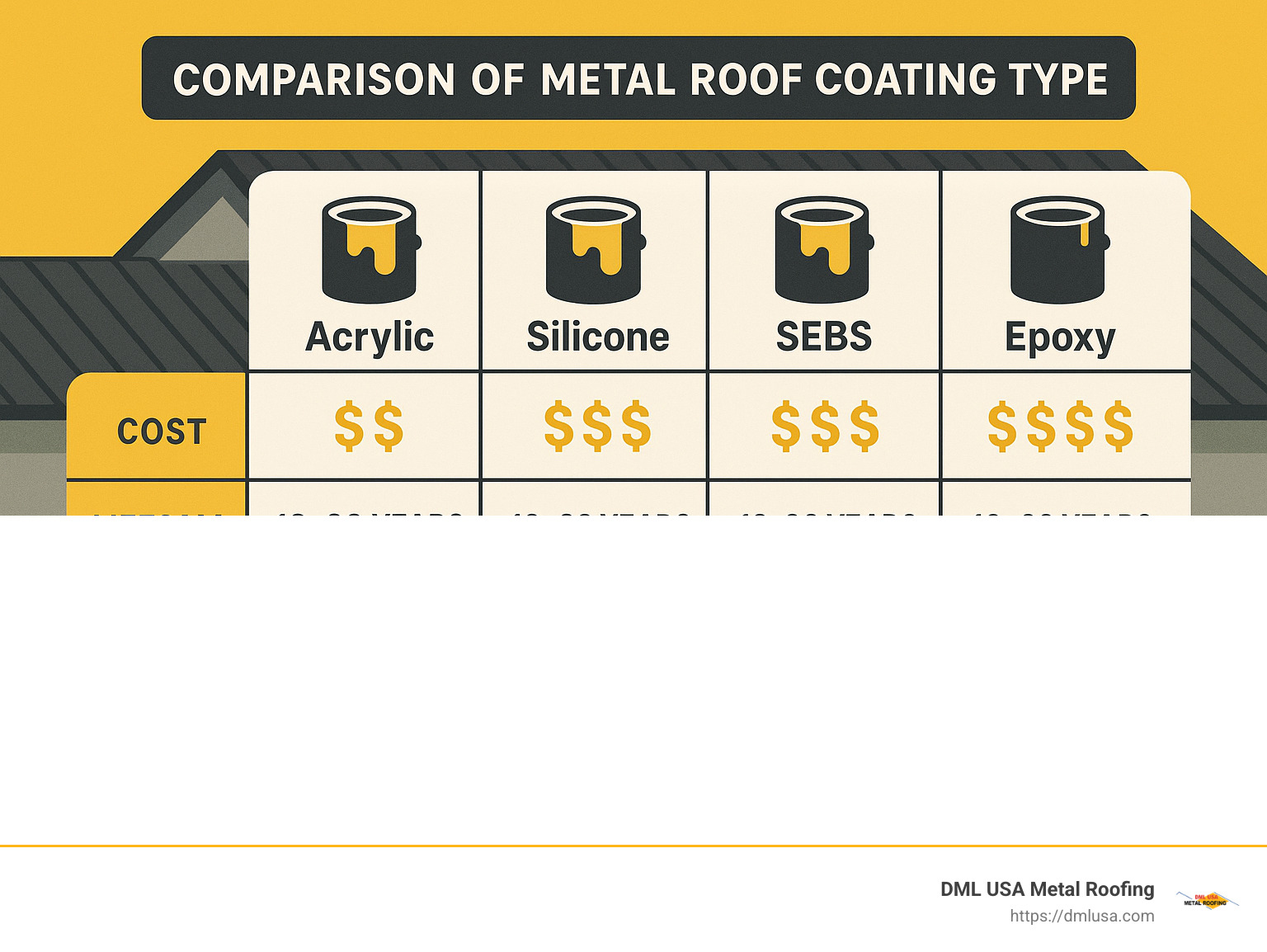

| Coating Type | Cost Per Sq Ft | Reflectivity | Typical Recoat Cycle | Best Application |

|---|---|---|---|---|

| Acrylic | $1.50-2.50 | 85-88% | 7-12 years | General purpose, UV resistance |

| Silicone | $2.50-4.00 | 80-85% | 15-20 years | Ponding water areas |

| SEBS Rubber | $2.00-3.50 | 87% | 10-15 years | Extreme weather, flexibility |

| Epoxy-Hybrid | $3.00-5.00 | 75-80% | 15-20+ years | Maximum adhesion, durability |

| PVDF/Kynar | $4.00-7.00 | 70-75% | 20-30+ years | Premium color retention |

Acrylic Coatings

Think of acrylic coatings as the reliable sedans of the coating world – they get the job done well at a reasonable price. These water-based formulas have become the go-to choice for many building owners for good reason.

Water-Based Formula means cleanup is as simple as soap and water. The low odor is a huge plus when coating a roof over an occupied building – nobody wants their office smelling like chemicals for days!

High Reflectivity is where acrylics truly shine (literally). With ratings often exceeding 85%, these coatings bounce back the sun’s rays instead of absorbing them, keeping your building cooler and your energy bills lower.

Fast Cure times mean less disruption to your business operations. In warm weather, most acrylic coatings dry to the touch within hours.

The main drawback? Ponding Water Limitations. If your roof tends to collect standing water, acrylics might not be your best bet as they can soften and degrade under those conditions.

Quality elastomeric roof coatings are popular acrylic options that many of our customers have used with success. As one contractor told me recently, “We’ve been using premium acrylics for years on smaller projects. They’re affordable and hold up well in our Illinois climate.”

Silicone Coatings

Silicone coatings are like rain boots for your roof – they excel at keeping water out, no matter what.

Moisture-Cure Technology means these coatings actually use humidity in the air to cure, making them ideal for application in damp conditions when other coatings might fail.

Ponding-Water Resistance is silicone’s superpower. These coatings can sit underwater for extended periods without breaking down, making them perfect for flat or low-slope metal roofs where drainage might be an issue.

The downside? Slippery Surface characteristics mean maintenance can be tricky. After application, silicone coatings remain somewhat slick even when fully cured. And at a Higher Cost (typically 50-100% more than acrylics), they represent a bigger investment upfront.

High-quality 100% Silicone Reflective Roof Coatings offer exceptional waterproofing for challenging roof conditions.

SEBS Rubber Coatings

SEBS (Styrene Ethylene Butylene Styrene) rubber coatings are like the all-season tires of the roofing world – they perform well in virtually all conditions.

Primer-Free Application can be a huge time-saver. Leading manufacturers of this technology (in development since 1978) point out that their SEBS systems often can be applied directly to properly prepared metal, eliminating a step in the process.

87% Reflectivity means these coatings deliver excellent energy efficiency, helping keep your cooling costs down during our hot Illinois summers.

Extreme Flexibility is particularly valuable in our Midwest climate, where temperatures can swing from -20°F in winter to 95°F in summer. These coatings flex with your metal roof through these extreme changes without cracking or separating.

The main drawback is their Solvent-Based Formula, which means cleanup requires solvents rather than water, and VOC content is typically higher than water-based alternatives.

Epoxy-Hybrid Systems

Epoxy-hybrid coatings are the luxury SUVs of the coating world – more expensive, but offering premium performance and durability.

Self-Plasticizing Technology used by quality manufacturers combines epoxy strength with rubber-like flexibility, creating a coating that’s tough yet adaptable.

99.9% Memory Recovery means these coatings can stretch with your roof’s movement and return to their original shape time after time, season after season.

Excellent Adhesion to metal substrates makes these coatings ideal for roofs with existing rust or corrosion issues. They grip the surface tenaciously, even in challenging conditions.

The trade-off is their Multi-Step Application process, which typically requires more labor and expertise to install correctly. But as many of our customers have found, the extra effort pays off in exceptional longevity.

PVDF/Paint-Finish Topcoats

PVDF coatings (including premium brands) are the Rolls-Royces of metal roof coatings – the premium option when appearance and longevity are your top priorities.

AAMA 2605 Compliance means these coatings meet the highest industry standard for exterior finishes. This is serious business – these standards require coatings to maintain their appearance after years of Florida sun exposure testing.

Color-Fast Performance is where PVDF truly excels. We’ve seen buildings with phases constructed nearly a decade apart that show virtually no color difference when using these premium coatings.

Chalk Resistance keeps your roof looking fresh and clean for decades, without the whitish degradation that affects most other coating types.

The main limitation? Typically Factory-Applied means these coatings are usually applied during manufacturing rather than in the field. However, some manufacturers now offer field-applied versions of their premium PVDF formulations.

At DML USA Metal Roofing, we’ve seen all these coating types in action across Illinois, and we’re happy to help you determine which one makes the most sense for your specific metal roof conditions. The right coating can transform an aging roof into a high-performance asset that protects your building for many years to come.

For more technical information about metal roof coatings and their performance characteristics, you can visit the Cool Roof Rating Council website, which provides independent ratings and research on roofing products.

7 Problems Quality Coatings Solve on Metal Roofs

Let’s face it – metal roofs are tough, but they’re not invincible. Over time, even the best metal roofs start showing their age. The good news? Quality coatings from reputable metal roof coating companies can address these common headaches without breaking the bank or requiring a full replacement.

1. Leaks

Nothing ruins your day faster than water dripping onto your desk or inventory. As metal roofs age, they develop weak points – seams pull apart, fasteners back out, and tiny pinholes form through corrosion.

The best epoxy-hybrid coatings don’t just promise to fix leaks – they come with a 12-year guarantee to keep your roof watertight. By creating a seamless membrane across the entire roof surface, quality coatings seal these vulnerable areas before they turn into costly interior damage.

2. Rust Creep

Rust is like a slow-moving wildfire on metal roofs. Once it starts, it spreads relentlessly. I’ve seen small rust spots turn into major structural issues within just a couple of years here in Illinois, where our harsh winters and humid summers create perfect conditions for corrosion.

Quality coatings demonstrate this benefit beautifully. Rather than replacing a severely rusted roof, restoration with specialized coatings can encapsulate the existing corrosion and prevent moisture from reaching the metal. The result? Major budget savings and a roof that’s ready for many more years of service.

3. Seam Fatigue

Metal roofs are constantly moving. When the sun beats down, they expand. When temperatures drop at night, they contract. This daily dance puts enormous stress on seams and fasteners, eventually causing them to fail.

Modern elastomeric coatings are designed to flex with this movement. The best formulations offer “500% elongation with 99.999% memory retention” – in plain English, that means they can stretch to five times their original size and bounce back perfectly, over and over again. This flexibility maintains the coating’s integrity despite the metal’s constant movement, keeping those seams sealed tight.

4. Energy Loss

Dark or uncoated metal roofs are basically giant solar collectors, absorbing heat that transfers into your building. In summer, this can send your cooling bills through the roof (pun intended).

Reflective coatings make a dramatic difference. Top SEBS rubber products offer “87% reflectivity to reduce surface temperatures,” which means most of the sun’s heat bounces right off instead of being absorbed. Industry studies note that coated metal roofs can “help regulate a home’s temperature, decreasing heating and cooling bills by up to 40%.” When I’m walking on a coated vs. uncoated roof on a sunny day, the temperature difference is immediately obvious – often 20-30 degrees cooler on the coated surface.

5. Noise

If you’ve ever been in a metal-roofed building during a rainstorm, you know the soundtrack – that constant drumming that makes conversations difficult and can disturb building occupants.

Many elastomeric coatings add a surprising benefit: noise reduction. Quality liquid rubber products “cure into a seamless, rubbery membrane that also acts as a sound deadener.” This additional layer absorbs and dampens impact noise, making your building more comfortable during those Illinois thunderstorms we experience so frequently.

6. UV Degradation and Chalking

The sun is relentless. Its ultraviolet radiation breaks down the molecular bonds in paint and coatings over time, leading to chalking (that white powdery substance), fading, and eventual failure of your roof’s protective finish.

Premium coatings include UV stabilizers and reflective pigments specifically designed to resist this degradation. The best silicone-modified polyester coatings offer “extreme resistance to abrasion, chipping and marring” even after years of sun exposure. These advanced formulations keep your roof looking good and performing well despite constant UV bombardment.

7. Costly Tear-Offs

Perhaps the biggest problem solved by quality roof coatings is helping you avoid the nightmare of complete roof replacement. Tearing off and replacing a metal roof isn’t just expensive – it’s disruptive to your operations, potentially exposes your building to weather damage during the process, and generates tons of waste.

Industry experts put it in dollars and cents: “Restoring a roof yields on average 300% savings compared to full replacement.” That’s a compelling return on investment that makes coating an attractive option for building owners looking to extend roof life while managing maintenance budgets responsibly.

For more scientific research on how cool metal roof coatings work to solve these problems, visit the Department of Energy’s Cool Roofs resource.

At DML USA Metal Roofing, we’ve seen these benefits across countless projects. A quality coating system can transform a problematic roof into a high-performing asset that protects your building for years to come – often at a fraction of replacement cost.

Product Roundup: Innovations Driving Today’s Leaders

The metal roofing world is buzzing with exciting innovations that are making coatings perform better than ever before. As someone who’s spent years in the industry, I’ve watched these technologies evolve from simple “roof paint” into sophisticated systems that truly transform aging metal roofs. Let’s explore what’s making waves among leading metal roof coating companies today.

Reflective Nanotech Pigments

Remember when choosing a light color was your only option for energy efficiency? Those days are gone! Today’s advanced coatings use incredibly tiny ceramic or titanium dioxide particles that dramatically boost solar reflectivity while giving you more color choices.

Sherwin-Williams has been particularly impressive in this space. Their Cool metal roofing SR coatings can help keep buildings cooler and reduce energy costs even in darker colors. This means you don’t have to sacrifice aesthetics for performance anymore.

Primerless Adhesion Systems

One of my favorite recent developments is the elimination of separate primer coats. This might sound like a small change, but it makes a huge difference in project timelines and labor costs.

Inland Coatings has been a pioneer here with their primer-free SEBS systems. As they explain, these coatings “save time and labor by eliminating the need for a separate primer” while still gripping tightly to properly prepared metal. For building owners and contractors alike, this means faster completion and less disruption.

Zero-VOC Formulas

Green building isn’t just a trend—it’s the future. That’s why I’m excited about the new zero-VOC formulations that perform beautifully without releasing harmful compounds into the air.

Castagra’s Ecodur+ stands out as a “100% sustainable roof coating with zero VOCs, BPA, and toxicity.” This makes it perfect for environmentally sensitive projects or buildings where air quality is a priority, like schools or healthcare facilities.

Elastomeric Hybrids

Sometimes two technologies are better than one. That’s the thinking behind the new hybrid coatings that combine different polymer types to create something truly special.

ArmorGarage has developed what they call a “self-plasticizing epoxy and rubber-fortified acrylic formulation.” In plain English, they’ve created a coating that forms a seamless protective layer with incredible bounce-back properties—99.99% memory recovery, to be exact. This means the coating can stretch with your roof during temperature changes and snap right back without cracking.

High-Solids Fast Cure

Nobody likes waiting around for paint to dry, especially when rain clouds are looming. Modern high-solids formulations cure faster while leaving more material on your roof.

As ArmorGarage points out, their coatings contain “65% solids content versus >50% loss in typical water-based coatings.” This means more protection stays on your roof rather than evaporating away, and you can complete projects faster with less weather vulnerability.

Cold-Weather Application

Here in Illinois, we know all about challenging weather conditions. Thankfully, newer coating formulations allow for successful application even when temperatures drop.

Some modern elastomeric coatings remain “flexible down to -40°F,” which is a game-changer for year-round projects. At DML USA Metal Roofing, we’ve been able to help customers with tight schedules complete their coating projects even during our chilly Illinois winters.

Renewable Warranties

Perhaps the most customer-friendly innovation is the concept of renewable warranties. Rather than starting from scratch when a coating reaches the end of its initial warranty period, some companies now offer simple maintenance coats that renew full protection.

Acrymax has been a leader with their “renewable warranties via recoats extending system lifetimes from 5 to 20 years.” This creates a sustainable approach to roof management that avoids costly tear-offs while extending protection indefinitely.

At DML USA Metal Roofing, we’ve seen how these innovations have transformed what’s possible with metal roof coatings. The sophisticated systems available today truly extend roof life while improving performance and reducing environmental impact—a win for your budget, your building, and our planet.

Future Trends to Watch in the Metal Roof Coating Space

The world of metal roof coatings is changing faster than ever, with exciting innovations just around the corner. As someone who’s watched this industry evolve over the years, I’m particularly excited about these emerging technologies that are changing how we protect and improve metal roofs.

AI Moisture Scanning

Remember the days when finding hidden moisture meant guesswork and luck? Those days are ending. New AI-powered moisture detection systems are revolutionizing how we prepare roofs for coating.

These smart systems use artificial intelligence combined with infrared scanning to pinpoint exactly where moisture might be hiding in your roof system. At DML USA Metal Roofing, we’ve seen how this technology prevents the costly mistake of coating over wet areas that would later bubble, peel, or accelerate corrosion. It’s like having x-ray vision for your roof!

Drone-Assisted Inspections

Drones aren’t just for amazing aerial photography anymore. They’re becoming essential tools for thorough roof inspections before, during, and after coating applications.

Not only does this technology improve safety by keeping workers off dangerous roof areas, but it also provides incredibly detailed documentation of your roof’s condition. We’re seeing metal roof coating companies use drones to create comprehensive “before and after” records that validate warranty claims and prove the quality of their work. The precision these flying assistants offer is truly remarkable.

Bio-Based Resins

The days of entirely petroleum-based coatings are numbered. Innovative manufacturers are now incorporating plant-derived ingredients like soybean oil and other renewable resources into their formulations.

What’s impressive is that these eco-friendly alternatives aren’t just better for the planet – they often outperform traditional coatings in flexibility and adhesion. For building owners concerned about their environmental footprint, these bio-based options offer performance without compromise. As one contractor told me recently, “My customers sleep better knowing their roof coating didn’t drain another oil well.”

Infrared-Reflective Colors

Remember when energy-efficient meant “white roof only”? Those limitations are disappearing thanks to infrared-reflective pigment technology.

These advanced pigments allow dark-colored coatings to reflect much more solar energy than was previously possible. Now building owners can choose attractive darker colors while still enjoying significant energy savings. This is especially important for historic buildings or properties where aesthetics are a primary concern.

ESG Reporting Integration

Environmental, Social, and Governance (ESG) reporting has moved from “nice to have” to “must have” for many commercial building owners. Forward-thinking metal roof coating companies are responding by providing detailed documentation of how their products contribute to sustainability goals.

Quality metal roof coatings support ESG objectives through reduced energy consumption, extended material lifecycles, minimized construction waste, and improved indoor comfort. These benefits translate directly into reportable metrics that help building owners demonstrate their commitment to sustainability – something increasingly important to tenants, investors, and regulatory bodies.

Tax-Credit Alignment

Money talks, and smart building owners are listening to the sound of tax incentives. As energy efficiency programs evolve at federal, state, and local levels, coating manufacturers are ensuring their products qualify for available credits and rebates.

Here in Illinois, we at DML USA Metal Roofing stay current on these programs because they can significantly offset the initial investment in a quality coating system. In some cases, these incentives can reduce the effective cost by 20-30%, dramatically improving ROI and shortening payback periods.

The future of metal roof coatings is brighter than a fresh coat of high-reflectivity acrylic! As these technologies continue to advance, building owners who stay informed will make smarter decisions about their roofing assets. With each innovation, metal roofs become more durable, more energy-efficient, and more environmentally responsible.

At DML USA Metal Roofing, we’re excited to see how these trends develop and to help our customers benefit from these advancements. After all, a better-protected roof means a better-protected building – and that’s something worth looking forward to.

Frequently Asked Questions about Metal Roof Coating Companies

How long should a premium coating last before a recoat is needed?

When you invest in a quality roof coating, you want it to last—and the good news is that premium products deliver impressive longevity. Most high-end metal roof coatings provide 10-20 years of protection before you’ll need to think about recoating.

The specific lifespan varies by formulation type. Silicone and epoxy-hybrid coatings typically offer the longest service life, while acrylics might need refreshing a bit sooner. ArmorGarage, for instance, backs their product with a “12-year guarantee,” though they note the “typical service life is 15–20 years before recoating.” Similarly, Acrymax offers “system warranty options ranging from 5 to 20 years” with the ability to extend protection through simple maintenance coats.

Your local environment plays a huge role in how long your coating will last. Here in Illinois, where we experience both scorching summers and frigid winters, we typically see 10-15 years of excellent performance from quality coating systems. Buildings in areas with extreme UV exposure or frequent severe storms might need maintenance a little sooner.

Think of premium metal roof coatings like a good car—with proper maintenance and occasional check-ups, they’ll serve you reliably for many years beyond what you might expect.

Do coatings qualify for energy-efficiency tax incentives?

Yes! Many reflective metal roof coating companies offer products that qualify for valuable energy efficiency incentives at federal, state, and local levels. These programs can significantly offset your initial investment, making quality coatings even more affordable.

To qualify for federal programs, coatings typically need to meet specific Solar Reflectance Index (SRI) values and be applied to appropriate building types. The exact requirements change periodically, so it’s worth checking current guidelines before making your selection.

Beyond federal incentives, many utility companies offer their own rebate programs for reflective roof coatings that reduce peak energy demand. These local programs can sometimes provide immediate savings that complement longer-term tax benefits.

At DML USA Metal Roofing, we’ve helped countless Illinois customers steer these incentive programs to maximize their return on investment. We’ve seen how the combination of energy savings and available tax credits can dramatically reduce the effective cost of a quality coating system—sometimes paying for itself much faster than expected.

Can coatings be applied in cold or humid climates?

Modern coating technology has come a long way in expanding application parameters, but Mother Nature still sets some boundaries. The good news is that with proper planning and product selection, successful applications can happen nearly year-round in most climates.

Temperature considerations are important for proper curing. Most manufacturers specify minimum application temperatures between 40-50°F, though some specialized formulations can perform at lower temperatures. The main concern isn’t just applying the coating—it’s ensuring it forms a proper protective film as it cures.

Humidity factors affect different coating types in interesting ways. Moisture-cured silicones actually use atmospheric humidity as part of their curing process, while water-based acrylics dry more slowly when humidity is high. Professional applicators carefully monitor dew point calculations to ensure the substrate temperature is appropriate relative to ambient conditions.

Here in the Midwest, we face some unique climate challenges. Around Chicago and Northlake, we carefully schedule coating projects with seasonal conditions in mind. Spring and fall typically offer ideal application windows, though we’ve successfully completed projects in nearly every month of the year by selecting the right products for the conditions.

Some metal roof coating companies directly address these seasonal challenges in their product development. Castagra, for example, has published helpful guidance specifically addressing “Can You Apply Roof Coatings In Cold Weather?” to help contractors and building owners work through challenging conditions.

With proper planning and product selection, your metal roof coating project can proceed successfully even in less-than-ideal weather conditions—just one more reason these versatile systems have become so popular for commercial building owners looking to extend roof life and improve energy efficiency.

Conclusion

The right metal roof coating applied by qualified professionals can transform an aging, problematic metal roof into a high-performance, energy-efficient asset with decades of additional service life. As we’ve explored throughout this article, metal roof coating companies offer a wide range of innovative solutions to address virtually any metal roof challenge.

When you invest in quality metal roof coatings, you’re not just patching up problems – you’re completely reinventing your roof’s performance and lifespan. The financial benefits are compelling – coating typically costs just one-third to one-half what you’d pay for complete replacement, while adding 10-20 years to your roof’s life. That’s real value that impacts your bottom line immediately.

But the advantages go far beyond just stopping leaks. Modern reflective coatings can slash your cooling costs by up to 40%, putting money back in your pocket month after month. Many of these systems qualify for energy incentive programs too, sweetening the deal even further.

I’ve seen how building owners light up when they realize the environmental benefits as well. By avoiding a tear-off, you’re keeping tons of roofing waste out of landfills. It’s a decision you can feel good about, especially as sustainability becomes increasingly important to stakeholders and customers alike.

What surprises many of our clients is how these coatings actually improve overall roof performance. Beyond just waterproofing, quality coatings improve fire resistance, strengthen wind uplift ratings, and let’s be honest – they make your building look fantastic too! There’s something satisfying about seeing a freshly coated roof gleaming in the sunlight.

The warranty protection offered by leading manufacturers provides valuable peace of mind. Some programs even let you renew your warranty through simple maintenance coats – potentially extending protection indefinitely without ever needing a full replacement.

Here at DML USA Metal Roofing, we manufacture high-quality, affordable metal roofing products that pair perfectly with today’s advanced coating systems. Our metal roofing is built for durability, energy efficiency, and maintenance-free performance, creating the ideal foundation for coating applications when the time comes.

For our Illinois neighbors, particularly around Chicago and Northlake, we understand the specific regional challenges you face. Our team can help evaluate your current roof condition, recommend appropriate coating solutions, and connect you with qualified application contractors who know their stuff.

To find how our metal roofing products provide the ideal substrate for future coating applications, visit our products page. When you choose DML USA Metal Roofing, you’re investing in roofing solutions that stand the test of time and maximize any coating investment you make down the road.

The days of replacing perfectly good metal roofs just because they’re showing signs of age are over. With today’s advanced coating technologies, your metal roof can continue performing beautifully for decades to come—with no more leaks and lower energy bills to boot!