The Backbone of the Roofing Industry

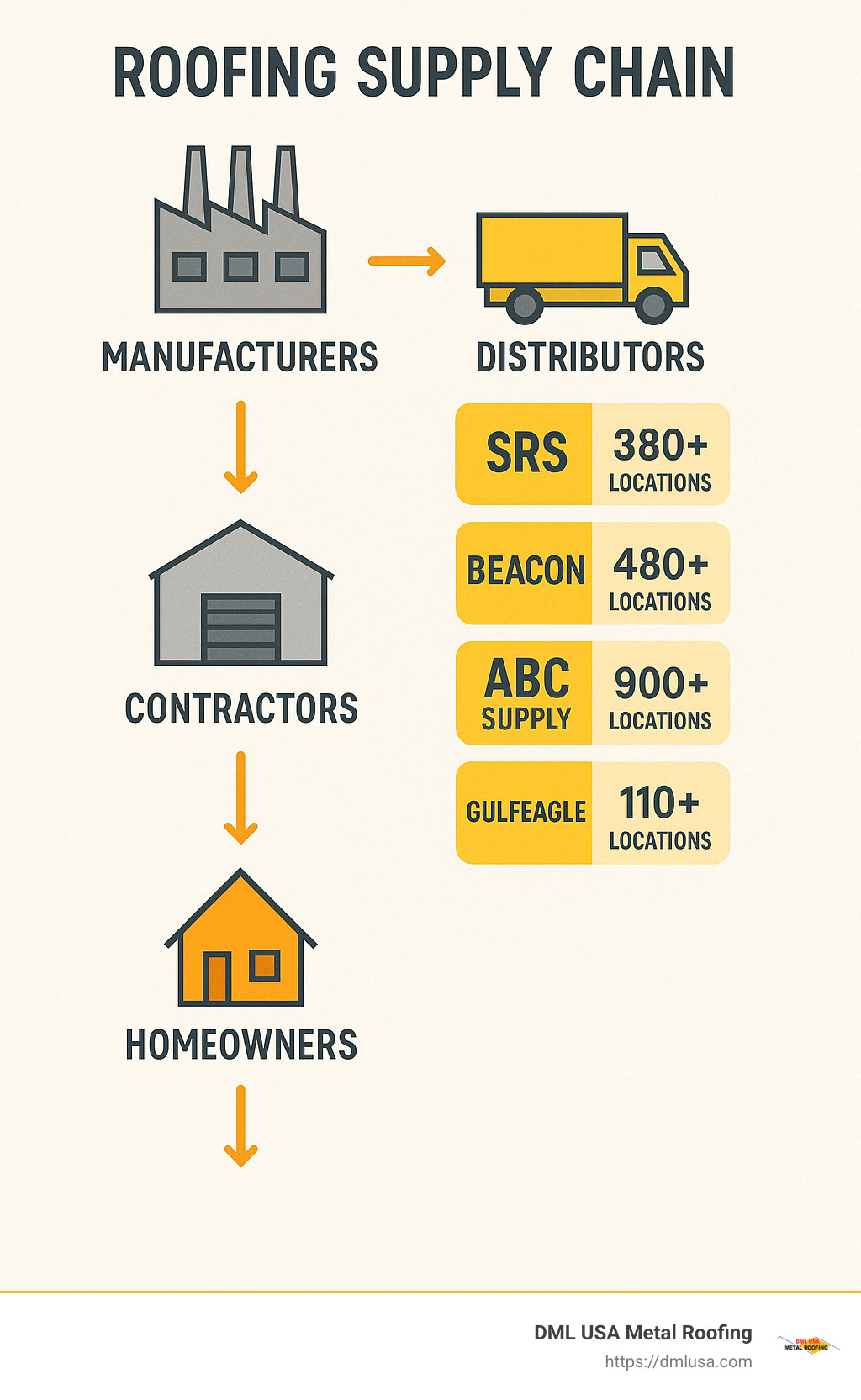

Roofing distribution represents the vital network that connects manufacturers with contractors and ultimately homeowners. The roofing distribution landscape is rapidly evolving in 2025, with significant consolidation reshaping the market. Major players are expanding through acquisitions while also diversifying into emerging sectors like sustainable roofing solutions. Technology adoption has become a competitive necessity, with distributors implementing e-commerce platforms and exploring AI applications to address workforce challenges.

For homeowners, understanding this network is crucial – your roofing contractor’s access to quality materials depends on reliable distributors who maintain inventory, provide technical support, and ensure timely delivery of the products that will protect your home.

“At the end of the day, our goal is to grow for a variety of different reasons, right? It’s not just to hit a number on a board,” notes Kurt Schwahn, chief revenue and operations officer at a major distribution company, highlighting the strategic approach many distributors are taking.

Independent distributors continue to find success by serving niche markets and specific communities, often providing personalized service that larger companies cannot match. The Latino community represents one of the fastest-growing segments in the contractor industry, prompting many distributors to hire Spanish-speaking employees and develop culturally relevant services.

I’m Adam Kadziola from DML USA Metal Roofing, a family-owned manufacturer that works closely with roofing distribution networks to ensure our high-quality metal roofing products reach homeowners across Illinois and beyond. My experience navigating supply chains and building relationships with distributors has given me knowledge of how quality materials move from factory to roof.

Current Trends and Challenges in Roofing Distribution

The roofing distribution landscape is changing faster than a Midwest weather pattern. A recent major acquisition in the industry for over $18 billion sent ripples through the entire industry. This wasn’t just another business deal – it signaled that big-box retailers are making serious moves into the professional contractor space.

But consolidation is just one piece of the puzzle. Today’s distributors are juggling several challenges at once. Workforce shortages have left many scrambling to fill positions, while technology demands continue to evolve at breakneck speed. The contractor customer base itself is changing, with more diverse demographics requiring new approaches to service. Add in the pressure to expand product offerings and persistent supply chain hiccups, and you’ve got a recipe for significant industry change.

At DML USA Metal Roofing, we’ve watched these changes unfold firsthand. We’ve adapted by focusing on relationships with distributors who reliably deliver our metal roofing products to contractors throughout Illinois and neighboring areas. These partnerships have become more crucial than ever in this shifting landscape.

The Impact of Industry Consolidation

Remember when roofing distribution was mostly local businesses serving their communities? Those days are fading fast. The market that once featured dozens of regional players has transformed into one where national giants with hundreds of locations dominate the scene.

This consolidation brings mixed results for everyone involved. The big distributors now wield impressive buying power, allowing them to negotiate better deals with manufacturers like us. Their expanded geographic reach means contractors can often find consistent service across different regions. And with standardized processes, many operations run more smoothly than before.

But there’s a flip side. With fewer players in the game, competition may decrease, potentially leading to price increases down the road. For smaller, independent distributors, the pressure is intense – survival now depends on finding ways to stand out from the corporate giants.

Many independents have responded by getting specialized. Some focus exclusively on specific products like metal roofing, while others double down on serving particular geographic areas where their local knowledge gives them an edge.

As Kurt Schwahn wisely puts it: “Our goal is to stay within our lane because that’s what we do well. Our goal is to grow, but grow where it makes sense, not just hit a number.” This strategic thinking has become essential for distributors of all sizes.

Navigating Acquisitions in Roofing Distribution

The pace of buyouts in roofing distribution has gone from steady to frenzied in recent years. Beyond the headline-grabbing major retail-distribution deal, the acquisition trail runs long throughout the industry.

Regional distributors have expanded to over 140 branches nationwide through strategic acquisitions. Well-funded startups have made plays for established distribution networks. And national distributors have been on shopping sprees, acquiring numerous regional distributors to build networks of more than 530 locations.

These changes affect everyone in the supply chain. For contractors and homeowners, larger distribution networks often mean better product availability across wider areas – you’re less likely to hear “we don’t carry that in this location.” But something valuable can get lost in the shuffle: the personal relationships and local expertise that smaller distributors offer.

We’ve taken a balanced approach at DML USA Metal Roofing. By maintaining relationships with both national powerhouses and regional specialists, we ensure our metal roofing products remain readily available to contractors throughout Illinois, particularly near our Northlake and Chicago locations. This strategy gives us the best of both worlds – broad reach and personalized service – which ultimately benefits the contractors and homeowners who choose our products.

Technology Changing Roofing Distribution

The world of roofing distribution is experiencing a digital revolution. Remember the days when ordering materials meant a flurry of phone calls, faxes, and driving to the distributor’s counter? Those days are rapidly fading as new technologies transform how roofing materials move from manufacturers to contractors and ultimately to homeowners.

Today’s successful distributors aren’t replacing the handshake with the keyboard – they’re using technology to make those relationships even stronger. Digital tools have become essential companions that make everyone’s job easier while maintaining the personal touch that this industry was built on.

“From our perspective, it’s value-add, not a replacement. So our goal is to streamline and to gain efficiencies,” explains Kurt Schwahn, highlighting what we at DML USA Metal Roofing have always believed – technology should improve human connections, not replace them.

Contractors can now place orders at midnight after finishing a late estimate, track their deliveries while on a job site, instantly access detailed specifications on metal roofing options, and handle payments with a few clicks. What used to take hours of phone tag and paperwork now happens seamlessly in the background, letting everyone focus on what matters – delivering quality roofing materials to projects on time.

Digital Tools Enhancing Roofing Distribution

The digital change in roofing distribution has created win-wins for everyone in the supply chain. E-commerce platforms have become the workhorses of modern distribution, operating 24/7 so contractors can place orders whenever inspiration (or deadline pressure) strikes.

Mobile apps have become essential tools in contractors’ digital toolbelts. Today’s roofing professional might use their phone to scan a barcode for quick reordering, snap a photo to match a product, find the nearest branch with GPS, track deliveries in real-time, or even receive weather alerts that might impact their projects. All this technology travels with them from job site to job site, making every minute more productive.

At DML USA Metal Roofing, we’ve acceptd this digital shift by ensuring our metal roofing products are thoroughly documented in digital formats that seamlessly integrate with our distributors’ systems. When a contractor needs our durable metal roofing materials for a project in Illinois, they can access complete specifications, installation guides, and availability information without waiting for a callback or digging through a catalog.

The best part? These digital improvements allow distributors and manufacturers to focus more on providing expertise and solving problems rather than processing paperwork – strengthening relationships rather than replacing them.

The Role of AI in Roofing Distribution

Artificial intelligence isn’t just coming to roofing distribution – it’s already here, quietly changing operations behind the scenes. While still in its early stages, AI is proving to be a powerful ally against one of the industry’s biggest challenges: labor shortages.

As Chris Arrington, a senior credit officer at a major distributor, puts it: “[AI] is not going to be ‘you get to choose to have it,’ it’s going to be a need unless you can, in the next five years, soak up all the labor from all the other competitors and from different industries.”

AI is working its magic across the distribution landscape in ways that might surprise you. Smart inventory systems are now using historical data and weather forecasts to predict when contractors will need certain materials – ensuring that metal roofing panels are in stock before the rush after a major storm. Delivery trucks follow AI-optimized routes that save time, fuel, and headaches. Credit decisions that once took days now happen in minutes through automated systems.

For homeowners choosing DML USA Metal Roofing products, these AI advancements mean greater reliability. When your contractor orders our energy-efficient metal roofing system, the intelligent distribution network helps ensure those materials arrive exactly when needed – no delays, no excuses, just quality materials ready for installation.

Customer service is getting smarter too, with virtual assistants handling basic questions around the clock, freeing up human experts to tackle the complex challenges that require a personal touch. The future of roofing distribution will blend the efficiency of artificial intelligence with the irreplaceable value of human expertise. For more information about AI in distribution, you can visit this resource on Artificial Intelligence and Machine Learning in Supply Chain.

Diversification and Expansion in the Roofing Distribution Market

The roofing distribution landscape is evolving beyond traditional shingles and accessories. Today’s distributors are expanding their horizons, adding new product lines and services that complement their core offerings. This isn’t just about chasing new revenue—it’s a strategic approach to weather industry fluctuations while becoming more valuable to their contractor customers.

Think about it: when a contractor is already picking up roofing materials, wouldn’t it be convenient to grab siding or windows from the same supplier? Distributors are banking on this one-stop-shop approach, expanding into related exterior products, interior building materials, and even specialized services like takeoff and estimating.

At DML USA Metal Roofing, we’ve witnessed this change firsthand. Our Illinois-based manufacturing operation works with distributors who increasingly want to offer comprehensive solutions rather than isolated products. The most successful ones aren’t just selling materials—they’re becoming essential business partners to their contractors.

Embracing Renewable Energy in Roofing Distribution

Perhaps the most exciting frontier in roofing distribution is the integration of sustainable technology. The roof-energy connection makes perfect sense—both protect the home while offering prime real estate for energy efficiency. Forward-thinking distributors are recognizing this natural pairing.

“I think over the next five years, if you’re not embracing sustainability you’re going to get left behind,” warns Anthony Romero, capturing the urgency many in the industry feel. “There’s going to be a company that could offer comprehensive solutions, and that’s who the homeowners are going to end up choosing.”

This isn’t just speculation. Major industry players have publicly declared their intention to expand in this direction, leveraging existing networks and relationships. They recognize what we at DML USA have long understood—metal roofing and sustainability are perfect companions. Our metal roofing products are designed to be energy-efficient, with lifespans that far exceed traditional roofing materials.

The sustainability angle resonates with today’s homeowners too. Energy-efficient metal roofing creates an unbeatable solution for environmentally conscious consumers, especially when backed by available energy tax credits that DML USA Metal Roofing products qualify for.

Adapting to Demographic Changes

Walk into any roofing jobsite today, and you’ll likely notice a change from a decade ago. The contractor workforce is evolving, with the Latino community representing one of the fastest-growing segments in the industry. Smart roofing distribution companies aren’t just noticing this shift—they’re adapting their entire business models to accept it.

Sean McDevitt, a chief human resources officer at a major distributor, puts it plainly: “If the fastest-growing part of the workforce that’s going to make you successful speaks Spanish, you better figure out how to hire Spanish speakers, how to be successful, how to build a culture that’s welcoming to them, how to create a way so that they can advance once they get here.”

This isn’t just about translating existing materials (though that’s important). It’s about creating truly inclusive environments where diverse contractors feel valued and understood. Some distributors have gone all-in by establishing dedicated business units focused on serving specific communities.

Sol Cerrada, who leads one such initiative, explains the reasoning: “I believe when we started, there was a need for a more diverse market, where the Latino community could communicate easily and get the service in their own language.”

At DML USA Metal Roofing, our Illinois roots have taught us the value of serving diverse communities. Our team includes bilingual staff who ensure our high-quality metal roofing products are accessible to all contractors, regardless of language preference. We’ve seen how breaking down these barriers leads to better outcomes for distributors, contractors, and ultimately homeowners.

Overcoming Workforce Challenges in Roofing Distribution

Finding and keeping good people has become one of the biggest headaches in the roofing distribution world today. Walk into any distributor’s branch office or warehouse and you’ll likely hear the same story – they’re short-staffed and struggling to fill positions.

The challenge isn’t simple. Many experienced workers are heading toward retirement, taking decades of industry knowledge with them. Meanwhile, younger folks often don’t even consider careers in building materials distribution, with many drawn to tech companies or other industries that seem more cutting-edge.

“We’re competing for talent not just with other distributors, but with Amazon, Target, and every other business that needs warehouse staff and drivers,” explains a regional manager at a mid-sized distribution company. “And when they can offer similar pay with less physical demands, it gets tough.”

The physical nature of many roofing distribution jobs – loading heavy materials, driving delivery trucks in all weather conditions – adds another challenge to recruitment efforts. Many distributors have responded by boosting wages, improving benefits, and creating clearer career advancement paths to show potential employees this isn’t just a job, but a viable long-term career.

Building a Diverse Workforce

Smart roofing distribution companies have recognized that building a more diverse workforce isn’t just the right thing to do – it’s a business necessity. With contractor demographics changing rapidly, having employees who understand different communities and speak multiple languages creates a significant competitive advantage.

“When a Spanish-speaking contractor can walk in and communicate easily with our counter staff, it builds immediate trust and loyalty,” notes a branch manager in Chicago. “Those relationships are everything in this business.”

The numbers tell the story – approximately 85% of job postings at one major distributor now include speaking Spanish as either a requirement or preference. This shift reflects the growing Latino presence in the contracting industry, both as workers and business owners.

Forward-thinking distributors are reaching beyond traditional recruitment channels by partnering with trade schools, community colleges, and organizations serving underrepresented communities. They’re implementing mentorship programs to help new employees steer the industry and providing cultural awareness training for management teams.

At DML USA Metal Roofing, we’ve made diversity a cornerstone of our approach. Our Illinois locations in Northlake and Chicago serve incredibly diverse communities, and our team reflects this diversity. This helps us better understand the needs of the various contractors who install our metal roofing products across the region.

Technology as a Solution to Labor Shortages

While nothing replaces good people, technology is helping roofing distribution companies do more with fewer staff members. Smart distributors are investing in systems that automate routine tasks, allowing their teams to focus on what humans do best – building relationships and solving complex problems.

Warehouse automation has made significant inroads, with systems that help with everything from inventory management to order picking. Delivery operations have been transformed by route optimization software that helps drivers make more stops in less time while using less fuel.

Customer-facing technology has perhaps made the biggest impact. Self-service portals allow contractors to place routine orders 24/7 without needing to speak to a sales rep. Meanwhile, AI-powered chatbots handle basic customer service inquiries, freeing up human staff for more complex issues.

Charles Michaud, a vice president at a distribution company, acknowledges the human side of technology adoption: “It’s just a matter of explaining why it’s beneficial to maybe some of those of the older generation, where we say, ‘Hey, look, we can help you streamline. We can save you some time and effort.'”

The transition isn’t always smooth. Many experienced employees initially resist new technologies, seeing them as unnecessary complications to processes they’ve mastered over decades. Successful distributors invest in comprehensive training and highlight how technology makes jobs easier rather than replacing them.

At DML USA Metal Roofing, we support our distribution partners by providing detailed digital product information that integrates smoothly with their inventory systems. This helps ensure our high-quality metal roofing products are accurately tracked and readily available to contractors throughout Illinois, making life easier for distribution staff while improving service for customers.

Independent Distributors Maintaining Competitiveness

Despite the wave of industry consolidation, independent roofing distribution companies aren’t just surviving—they’re thriving by playing to their unique strengths. These smaller, often family-owned businesses have found ways to compete successfully against the national giants, proving that bigger isn’t always better in the distribution world.

What makes these independent distributors so resilient? It starts with relationships. Many have operated in their communities for decades, building trust that spans generations. When a contractor calls, they’re not speaking to a random customer service representative but often to someone they’ve known for years who understands their specific needs.

Local knowledge gives these independents another edge. They understand the regional building codes, weather challenges, and customer preferences unique to their areas. This local expertise is particularly valuable in places with specific architectural styles or climate concerns—like the Chicago area, where we at DML USA Metal Roofing serve customers through our trusted independent distribution partners.

Their specialization in specific product categories creates another competitive advantage. Rather than trying to be everything to everyone, many independents focus deeply on particular segments—whether that’s metal roofing, commercial materials, or specialty products. This focused approach allows them to offer expertise and inventory depth that broader distributors sometimes can’t match.

Flexibility might be their greatest superpower. Without layers of corporate approval, independent distributors can adapt quickly to changing market conditions, special customer requests, or unexpected opportunities. If a contractor needs a custom solution or faces a tight deadline, independents can often make decisions on the spot to help their customers succeed.

The personalized service these distributors provide creates loyal customers who value the relationship as much as the products. From customized delivery schedules to custom credit terms, independents can shape their offerings around specific contractor needs rather than forcing customers into standardized processes.

Many independent distributors are deeply involved in their communities, sponsoring local events, participating in trade associations, and building networks that strengthen their business ties. This community connection creates a loyalty that national chains struggle to replicate.

At DML USA Metal Roofing, we value our partnerships with independent distributors throughout Illinois. These relationships ensure contractors have access to our durable, maintenance-free metal roofing products through trusted local sources who truly understand the specific needs of Chicago-area builders and homeowners. While the distribution landscape continues to evolve, we believe there will always be a place for these nimble, customer-focused independents who bring our quality products to the market with a personal touch.

Frequently Asked Questions about Roofing Distribution

What are the current trends in roofing distribution?

The roofing distribution world is changing faster than ever in 2025. If you’ve been watching the industry, you’ve probably noticed some big moves happening.

First, there’s the wave of consolidation sweeping through the market. A recent multi-billion dollar acquisition made headlines, but it’s just one example of the bigger-is-better approach many companies are taking. These acquisitions are reshaping the competitive landscape in ways we haven’t seen before.

Beyond getting bigger, distributors are also getting broader. Many are expanding their product lines well beyond traditional roofing materials. Sustainable roofing systems are particularly important now, with major distributors openly stating their goals to become leaders in this growing segment. This makes perfect sense when you think about it – modern homeowners want roofing that’s both protective and environmentally responsible.

Technology is another game-changer. The days of placing orders by phone or fax are fading fast as digital platforms take over. E-commerce websites, mobile apps, and even AI systems are making it easier for contractors to get what they need when they need it.

The workforce is evolving too. With the Latino community representing one of the fastest-growing segments of roofing contractors, distributors are hiring more bilingual staff and creating culturally relevant services to meet their needs.

Finally, there’s a growing focus on sustainability. As homeowners become more environmentally conscious, distributors are expanding their eco-friendly options – something we at DML USA Metal Roofing have always prioritized with our energy-efficient metal roofing systems.

How is technology impacting roofing distribution?

Technology has completely transformed how roofing distribution works in recent years. What was once a business built on handshakes and paper orders has evolved into a digital ecosystem that works harder and smarter.

Digital ordering systems have replaced the old phone-and-fax routine, allowing contractors to place orders any time of day or night. This 24/7 access means no more waiting until Monday morning to get that urgent order in the system.

Behind the scenes, sophisticated inventory management software keeps track of every product in the warehouse, automatically triggering reorders when stock gets low. This means fewer stockouts and more reliable service for contractors.

Mobile applications have been a game-changer for busy contractors who are constantly on the move. With a few taps on their phones, they can check product availability, place orders, track deliveries, and manage their accounts – all while standing on a roof or driving between job sites.

Delivery tracking systems have also improved dramatically, giving both distributors and contractors real-time visibility into where materials are and when they’ll arrive. This transparency reduces those frustrating “where’s my order?” phone calls and helps everyone plan more effectively.

The newest frontier is AI and machine learning, which are beginning to help distributors predict demand patterns, optimize inventory levels, and automate routine tasks. This technology is particularly valuable as the industry grapples with workforce shortages.

As one industry executive put it: “From our perspective, it’s value-add, not a replacement. So our goal is to streamline and to gain efficiencies.” This perfectly captures the spirit of technology in roofing distribution – it’s about enhancing relationships, not replacing them.

At DML USA Metal Roofing, we’ve acceptd these technological advances by making our product information digitally accessible and compatible with various distribution systems. This makes it easier for contractors throughout Illinois to specify and order our high-quality metal roofing products.

How do workforce shortages affect roofing distribution?

Workforce challenges have become one of the biggest headaches in roofing distribution, affecting nearly every aspect of the business. These shortages aren’t just an inconvenience – they’re reshaping how the entire industry operates in 2025.

The most immediate impact is on day-to-day operations. With fewer warehouse workers, drivers, and counter staff, many distributors struggle to maintain their service levels. Some have had to reduce their hours, closing earlier or opening later because they simply don’t have enough people to staff their locations.

These shortages have also driven up labor costs significantly. As distributors compete for a limited pool of workers, wages and benefits packages have become more generous. While this is good news for workers, it puts pressure on margins and can ultimately affect product pricing.

Technology adoption has accelerated dramatically in response to these challenges. Self-service kiosks, automated warehouse systems, and digital ordering platforms help distributors do more with fewer people. As one senior executive noted, “[AI] is not going to be ‘you get to choose to have it,’ it’s going to be a need unless you can, in the next five years, soak up all the labor from all the other competitors and from different industries.”

Diversity initiatives have taken on new importance too. Many distributors are expanding their recruitment efforts to previously untapped demographic groups, particularly the Latino community. This isn’t just about finding warm bodies – it’s about building a workforce that reflects and understands an increasingly diverse contractor base.

Forward-thinking distributors are addressing these challenges through multiple approaches: competitive compensation, flexible scheduling, comprehensive training programs, and clear career advancement opportunities. Some are even offering sign-on bonuses and referral incentives to attract new talent.

At DML USA Metal Roofing, we understand these challenges well. We work closely with our distribution partners to provide detailed product information and training that helps their teams work more efficiently with our metal roofing systems. By streamlining these processes, we help distributors focus their valuable human resources where they matter most – building relationships with contractors and ensuring quality service.

Conclusion

The roofing distribution landscape is changing faster than a Midwest sky before a storm. From massive consolidations to the quiet resilience of family-owned independents, this industry keeps evolving while maintaining its essential purpose: connecting quality materials with the people who install them.

For homeowners and contractors alike, understanding this network matters more than you might think. That perfect metal roof protecting your home doesn’t magically appear—it travels through a carefully orchestrated distribution system that determines everything from availability to price to installation support.

As we’ve explored throughout this article, several key trends are reshaping roofing distribution in 2025:

Industry consolidation continues reshaping the competitive landscape, with major players growing larger while creating both challenges and opportunities for everyone else. Technology has transformed from a nice-to-have into an absolute necessity, with digital ordering, inventory management, and even AI becoming standard tools rather than futuristic concepts.

The most forward-thinking distributors are diversifying their offerings, particularly into sustainable roofing solutions—a natural extension that provides contractors with complementary product lines. Meanwhile, workforce challenges persist, prompting innovative approaches to recruitment, training, and retention, including important diversity initiatives and technological automation to fill gaps.

Through it all, independent distributors continue proving their value through specialized knowledge, community connections, and personalized service that national chains often struggle to match.

At DML USA Metal Roofing, we’ve built our business on strong relationships with quality distributors throughout Illinois. From our manufacturing facilities in Northlake and Chicago, we produce durable, maintenance-free metal roofing that offers exceptional protection against whatever Mother Nature throws at it—fire, wind, hail, you name it—while also qualifying homeowners for valuable energy tax credits.

We partner with both national networks and independent local distributors to ensure contractors throughout the region can easily access our products. This balanced approach helps us maintain wide availability while supporting the personalized service that makes such a difference in contractor satisfaction.

As the roofing distribution industry continues evolving, we remain committed to innovation, quality, and sustainability. After all, the materials protecting your home deserve nothing less than excellence at every step of their journey from our factory to your roof.

For more information about our products and where to find them through our distribution partners, please visit our Products page.