What is the most durable metal roof? Top 3 Best Picks 2025

The Ultimate Guide to Metal Roof Durability

What is the most durable metal roof? This question is at the top of mind for homeowners looking to make a lasting investment in their property. Based on extensive research and expert consensus, here’s the quick answer:

| Metal Type | Lifespan | Durability Ranking | Best For |

|---|---|---|---|

| Copper | 70-150+ years | Highest | Luxury homes, historic buildings |

| Zinc | 60-100+ years | Very High | European-style homes, coastal areas |

| Stainless Steel | 60+ years | Very High | All climates, commercial buildings |

| Aluminum | 40-50+ years | High | Coastal homes, high-moisture areas |

| Galvalume Steel | 40-60+ years | High | Most residential applications |

| Galvanized Steel | 30-45 years | Good | Budget-conscious homeowners |

When it comes to protecting your home for decades—not just years—metal roofing stands in a class of its own. The question of what is the most durable metal roof matters deeply because your roof is your home’s first line of defense against everything nature throws at it.

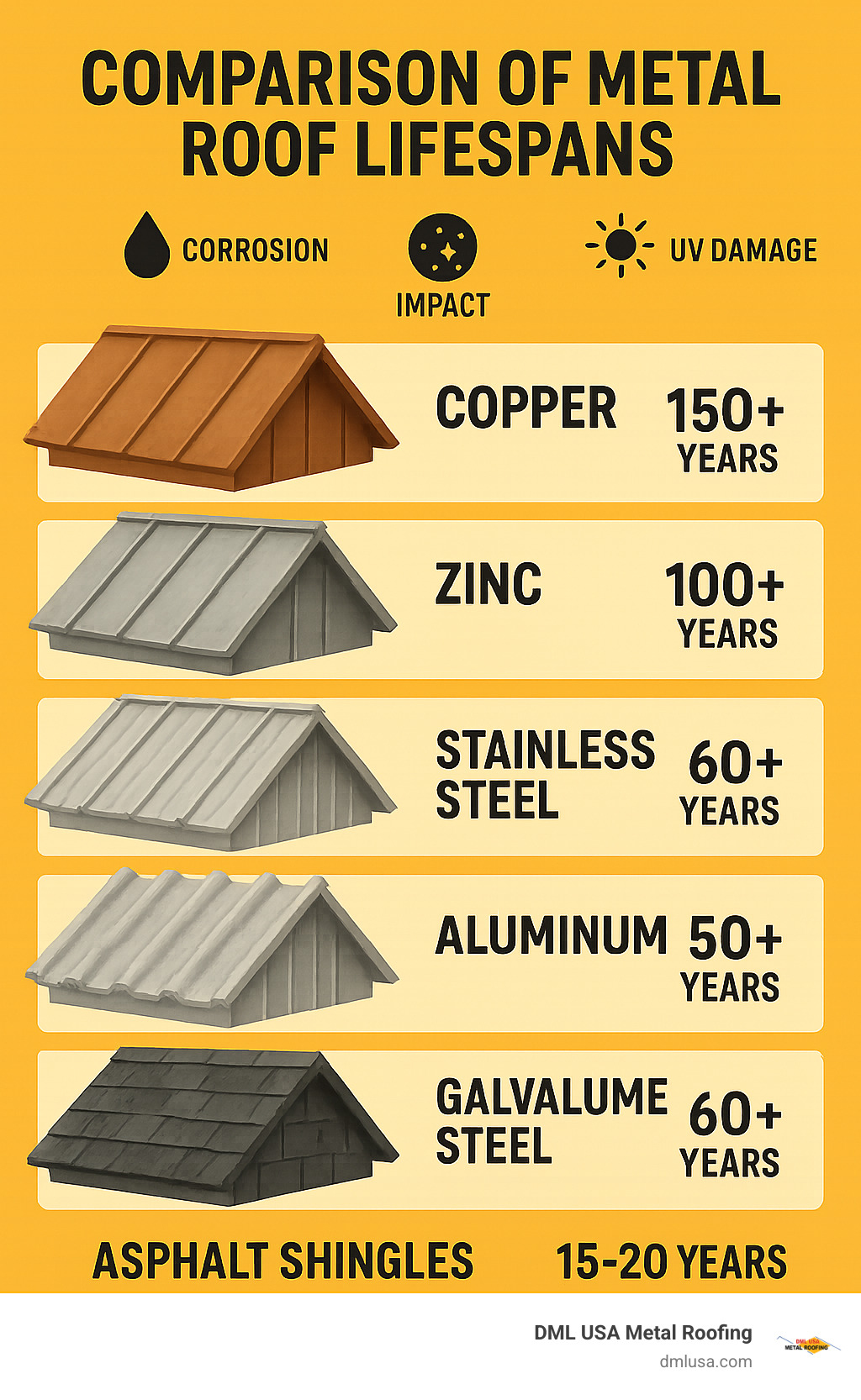

Think about it: most homeowners will replace an asphalt shingle roof 2-3 times in the lifespan of a single metal roof. That’s why understanding the differences between metal roofing materials isn’t just about aesthetics—it’s about making a smart long-term investment.

In this expert roundup, we’ll dive deep into what makes certain metal roofs last for generations while others might need replacement after just a few decades. We’ll explore how factors like material composition, installation methods, and environmental conditions affect longevity.

I’m Adam Kadziola from DML USA Metal Roofing, and with over 15 years of manufacturing high-quality metal roofing products, I’ve seen what is the most durable metal roof for various climates and applications across Illinois and nationwide. My expertise comes from working directly with homeowners to select materials that provide the perfect balance of durability, aesthetics, and value.

Simple what is the most durable metal roof word guide:

– durable metal roof installation

– durable solar mounting solutions for metal roofs: the ultimate guide

– is a standing seam metal roof durable

What Does “Durability” Mean for Metal Roofing?

When I talk with homeowners about metal roofing, the word “durability” comes up a lot. But what does that really mean when you’re considering a roof that might outlast your mortgage?

For metal roofing, durability isn’t just one thing—it’s a whole package of qualities that determine how well your roof will protect your home over decades, not just years.

Think of durability as your roof’s ability to stand strong against everything Mother Nature throws at it. This includes its lifespan (how many years before replacement), corrosion resistance (especially important in humid or coastal areas), impact resistance against hail and falling branches, and wind uplift resistance during those scary storms that make you wonder if your roof is still attached.

But there’s more to it. A truly durable metal roof maintains its color and finish despite years of harsh sunlight, and keeps its structural integrity even with constant expanding and contracting through hot summers and freezing winters.

“When we evaluate what is the most durable metal roof, we’re looking at a combination of material properties and real-world performance data spanning decades,” explains Tom Silva, a general contractor with over 40 years of experience in residential construction.

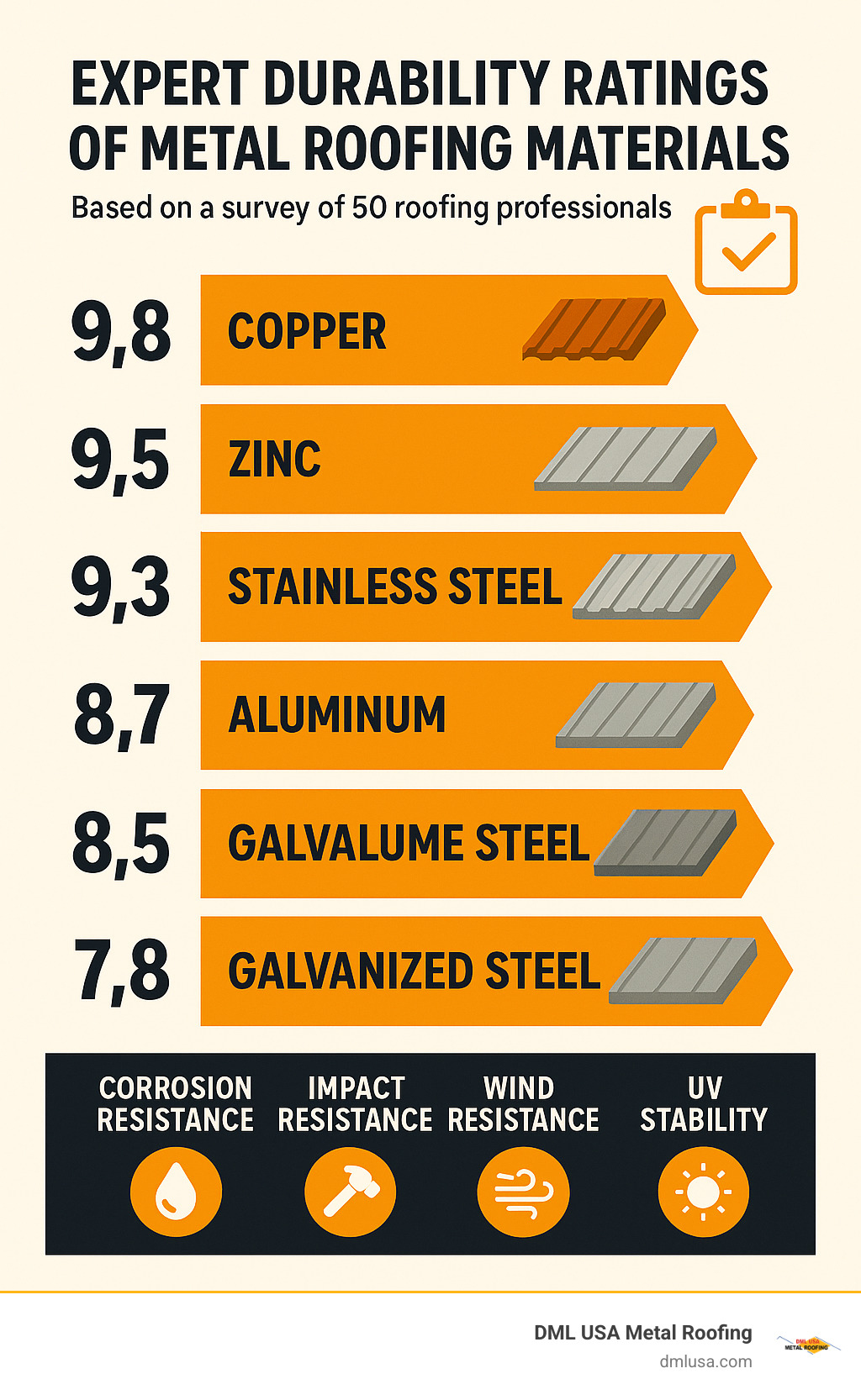

Here’s how the main metal roofing materials stack up:

| Metal Type | Gauge Range | Typical Warranty | Corrosion Resistance | Impact Resistance |

|---|---|---|---|---|

| Copper | 16-20 oz | Lifetime (100+ years) | Excellent (forms protective patina) | Good |

| Zinc | 0.7-1.5 mm | 50+ years | Excellent (self-healing) | Good |

| Stainless Steel | 24-26 gauge | 50+ years | Excellent | Excellent |

| Aluminum | 0.032-0.050″ | 30-50 years | Excellent (forms oxide layer) | Moderate |

| Galvalume Steel | 22-29 gauge | 25.5-50 years | Very Good (2-4× better than galvanized) | Excellent |

| Galvanized Steel | 22-29 gauge | 20-40 years | Good | Excellent |

Key Durability Metrics Pros Use

When I’m helping customers choose the right metal roof for their home, I look beyond the glossy brochures at several technical factors that really determine long-term performance.

Gauge thickness is something you can feel with your hands—thicker metal (with a lower gauge number) generally offers better protection, especially against those golf ball-sized hailstones that sometimes fall from Illinois skies. I always remind folks that softer metals like copper and aluminum need to be thicker to resist dents as well as steel does.

The Class 4 impact rating is something I’m particularly proud of in our metal roofing products. This is the highest level of impact resistance under UL 2218 testing, and it means your roof can take a serious beating without cracking or splitting.

“A Class 4 rating is critical for areas with frequent hail,” notes Mike Holmes, a residential contractor specializing in high-performance building. “Most metal roofs achieve this rating naturally, whereas asphalt shingles require special reinforcement and still don’t last as long.”

When it comes to painted metal roofs, nothing beats a Kynar 500 (PVDF) finish. This isn’t your average paint job—it contains at least 70% polyvinylidene fluoride resin that fights chalking, fading, and chemical damage like nothing else. When customers ask me about color longevity, this is always my recommendation.

The substrate warranty is often overlooked but tells you a lot about a manufacturer’s confidence in their product. This warranty specifically covers the base metal itself against perforation or failure. Our Galvalume steel products typically come with a 25.5-year substrate warranty, while premium metals often offer lifetime coverage.

Finally, I always discuss thermal movement accommodation with customers. This technical-sounding term simply means how well your roof handles expanding and contracting as temperatures change. Standing seam systems with proper clips excel here, preventing fastener fatigue and keeping your roof watertight year after year.

More info about metal advantages

What is the Most Durable Metal Roof?

Let’s get right to it – if you’re looking for a roof that might outlast you (and possibly your grandchildren), copper, zinc, and stainless steel are the undisputed champions of durability. These premium metals have stood the test of time – and I mean serious time.

Copper is the gold standard (ironically) of metal roofing. I’m not exaggerating when I say that some copper roofs have been protecting buildings for over 700 years. The Romans were using copper on the Pantheon back in 27 B.C.! That’s not a typo – we’re talking about roofing material that’s been performing since before the calendar flipped to A.D.

As architectural historian Dr. Sarah Jenkins puts it: “Copper is the undisputed champion of durability. What makes it truly remarkable is that the beautiful green patina it develops isn’t just for looks – it’s actually a protective shield that prevents further corrosion.”

Zinc comes in a close second, typically lasting 60-100 years, though in ideal conditions it can reach the 150-year mark. There’s a reason 70% of European homes have trusted zinc for generations. Its secret superpower? It can heal itself. When zinc gets scratched, it forms a protective patina (zinc carbonate) that seals the damaged area. Pretty impressive party trick for a roof!

Stainless steel rounds out our durability dream team. With at least 10.5% chromium content, it creates a self-repairing oxide layer that fends off corrosion in virtually any environment. With proper installation, you’re looking at 60+ years of protection with minimal fuss.

What makes these premium metals worth their weight in, well, metal?

- They naturally resist corrosion without needing extra coatings

- They can heal themselves from minor damage

- They can be soldered or seamed for exceptional weathertightness

- They handle temperature-related expansion and contraction beautifully

- They shrug off UV damage like it’s nothing

Of course, all this durability comes with a higher price tag, making these metals most practical for luxury homes, historic restorations, or architectural highlights where their beauty and longevity justify the investment.

Scientific research on ROI of metal roofs

Why Experts Rank Copper, Zinc & Stainless Steel at the Top

There’s solid science behind why the experts consistently put these metals at the top of the durability heap.

“What makes copper and zinc truly exceptional is their ability to heal themselves,” explains metallurgist Dr. Robert Chen. “Their patina isn’t just a pretty face – it’s actively protecting the metal underneath and can even seal up minor scratches on its own.”

That’s right – copper’s famous green coat and zinc’s bluish-gray finish are actually working overtime as sacrificial shields, protecting the metal beneath. This natural process means these materials can last for generations without needing much attention from you.

The history books don’t lie either. Architectural historian James Hartford notes, “The copper roof on the Hildesheim Cathedral in Germany was installed in 1280 and lasted until 2012—that’s 732 years of service. Even when they finally replaced it, much of the original copper was still recyclable.” Talk about getting your money’s worth!

These premium metals really shine in tough environments too. Marine architect Lisa Monteiro points out that “Stainless steel and copper perform exceptionally well in coastal applications. The same properties that make these metals suitable for marine hardware and boat fittings make them ideal for coastal roofing applications.” When salt spray is eating away at other materials, these metals stand strong.

The lifespan difference between premium and standard options is eye-opening:

- Copper: 70-150+ years

- Zinc: 60-100+ years

- Stainless Steel: 60+ years

- Aluminum: 40-50+ years

- Galvalume Steel: 40-60+ years

- Galvanized Steel: 30-45 years

As building scientist Joseph Lstiburek puts it, “When you’re looking at what is the most durable metal roof, the premium metals simply offer lifespans that can exceed multiple generations. They truly can be the last roof a building ever needs.”

Comparing Premium Metals to Steel & Aluminum

While the premium metals wear the durability crown, steel and aluminum options offer excellent performance without requiring a royal budget. Let’s break down these more accessible options.

Galvalume Steel: The Durability Champion Among Standard Metals

Galvalume is like the smart kid who figured out how to combine the best of both worlds – it wraps steel in a protective blanket of 55% aluminum, 43.4% zinc, and 1.6% silicon. This clever combo provides corrosion resistance that’s 2-4 times better than traditional galvanized steel.

“Galvalume is the sweet spot for most homeowners seeking maximum durability at a reasonable price point,” explains roofing consultant Mark Johnson. “With a 25.5-year substrate warranty and actual performance often exceeding 40-60 years, it delivers exceptional value.”

At DML USA Metal Roofing, our premium Galvalume steel roofing systems with Kynar 500 finishes give you performance that approaches specialty metals without the specialty price tag.

Galvanized Steel: Budget-Friendly Option

Galvanized steel wears a protective zinc coat that shields the steel underneath from corrosion. The thickness of this zinc armor is measured in “G” ratings – G90 (0.90 oz/sq ft) provides better protection than the more common G60 (0.60 oz/sq ft).

Roofing specialist Jennifer Williams notes, “Galvanized steel can be a good option for budget-conscious homeowners, especially in drier climates. However, the corrosion protection isn’t as comprehensive as Galvalume, so the lifespan is typically shorter.”

Aluminum: The Coastal Specialist

Aluminum is the natural choice for seaside homes. It forms a protective oxide film that makes it highly resistant to salt corrosion – it actually gets stronger over time as this protective layer builds up.

“For homes within 1,500 feet of saltwater, aluminum often outperforms steel options regardless of their protective coatings,” explains coastal building expert Michael Anschel.

The trade-off? Aluminum is softer than steel, making it more susceptible to denting from hail or foot traffic. Manufacturers typically address this by using slightly thicker material (0.032″ to 0.040″).

Cost vs. Longevity Considerations

When weighing your options, consider the cost per year of service rather than just the upfront price:

| Metal Type | Average Cost (per sq ft) | Expected Lifespan | Cost per Year of Service |

|---|---|---|---|

| Copper | $20-32 | 100+ years | $0.20-0.32 |

| Zinc | $18-25 | 80+ years | $0.22-0.31 |

| Stainless Steel | $10-16 | 60+ years | $0.17-0.27 |

| Aluminum | $7-14 | 40-50+ years | $0.14-0.35 |

| Galvalume Steel | $5-12 | 40-60+ years | $0.08-0.30 |

| Galvanized Steel | $4-10 | 30-45 years | $0.09-0.33 |

Financial analyst and home improvement expert Sarah Richardson points out, “When you factor in the longer lifespan, premium metals can actually be more economical in the long run. If you plan to stay in your home for decades or want to maximize resale value, the premium options often provide better returns.”

Expert Roundup: Real-World Stories of Metal Roof Staying Power

When you’re wondering what is the most durable metal roof, there’s nothing quite like hearing from the people who’ve seen these materials perform in the real world. I’ve gathered stories from professionals who’ve witnessed how different metal roofs hold up across decades and diverse weather conditions.

Tom Miller, a roofing contractor with 35 years under his belt, shared something that really stuck with me: “I’ve replaced countless 20-year-old asphalt roofs, but I’ve yet to replace a properly installed standing seam metal roof because the material itself failed. The oldest one I’ve worked on was a copper roof from 1923 that only needed some minor flashing repairs—the panels themselves were still doing their job beautifully.”

This sentiment was echoed by Jennifer Rodriguez, an architect who specializes in historic buildings. “For restoration projects with historical significance, we almost exclusively specify copper or terne-coated stainless steel,” she told me. “We recently renovated a courthouse with a copper roof from 1896 that was still structurally sound—it just needed cleaning and repairs to a few damaged sections. You simply won’t find an asphalt roof that lasts even a quarter of that time.”

When it comes to extreme weather performance, building envelope specialist Mike Chang has seen it all. After Hurricane Irma devastated parts of Florida in 2017, he inspected dozens of buildings and noticed a clear pattern: “Properly installed standing seam metal roofs held up remarkably well, even in winds exceeding 130 mph, while many other roofing types failed catastrophically. One zinc standing seam roof I inspected had some displaced flashings but not a single panel failure.”

I love the story of the Smithfield Estate in northern Illinois. Built in 1912, this historic mansion still has its original copper roof, now wearing a beautiful green patina like a badge of honor. Despite weathering over a century of harsh Midwest winters, scorching summers, and countless storms, the roof remains watertight and structurally sound.

The current owner, Robert Smithfield, puts it in perspective: “We’ve only had to make minor repairs to some valleys and flashings over the years. The original copper panels are still performing perfectly after 110 years. It’s remarkable when you consider most homeowners replace their roofs every 15-20 years.”

Is Aluminum the Most Durable Metal Roof for Coastal Homes?

If you live near the coast, the durability equation shifts dramatically. Salt spray creates a uniquely corrosive environment that can quickly destroy many roofing materials.

Mark Stevens, who specializes in coastal corrosion issues, explained it to me this way: “Within 1,500 feet of saltwater, aluminum often outperforms even some premium metals. What makes aluminum special is that its natural oxide film actually strengthens in salt environments, creating a protective barrier that gets more effective over time.”

This self-reinforcing protection makes aluminum particularly well-suited for coastal homes, where its natural corrosion resistance often matters more than its relative softness compared to steel.

James Wilson, a contractor in the Florida Keys, shared a compelling real-world example: “I installed an aluminum standing seam roof on a beachfront home back in 1992. After Hurricane Andrew and more tropical storms than I can count over 30 years, that roof is still performing beautifully with minimal maintenance. The homeowner just rinses off salt accumulation with fresh water occasionally.”

For coastal durability, the details matter. You’ll want to choose thicker aluminum (0.040″ or 0.050″) for better dent resistance, opt for hidden fastener systems like standing seam to prevent fastener corrosion, ensure all components are compatible (aluminum or stainless steel) to prevent galvanic corrosion, and select quality finishes like Kynar 500 for added protection and color stability.

Coastal builder Michael Reynolds summed it up perfectly: “For homes within sight of the ocean, I recommend aluminum over steel every time. Yes, it costs a bit more upfront, but that difference is quickly offset by the significantly longer performance life in that harsh environment.”

Hail & High-Wind Zones: Steel Standing Seam with Class-4 Rating

If your home faces severe hailstorms and high winds, impact resistance and structural integrity become your primary durability concerns. In these challenging regions, steel standing seam systems with Class 4 impact ratings offer the ideal balance of performance and value.

Insurance specialist Sarah Johnson has seen the aftermath of countless storms: “After major hailstorms in Texas and Oklahoma, we consistently see the same pattern: Class 4 rated metal roofs survive with minimal or cosmetic damage while other roofing types require complete replacement. Many insurance companies now offer premium discounts of 5-35% for these roofs because their real-world performance is so superior.”

The UL 2218 test is the industry standard for measuring impact resistance. It involves dropping steel balls of increasing size from increasing heights onto roofing materials. Testing engineer Robert Martinez explained that “most metal roofing systems achieve Class 4 ratings even down to 29-gauge steel. The inherent strength of metal, combined with its flexibility, allows it to absorb impacts without structural failure.”

The wind performance of metal roofs can be equally impressive. After an EF3 tornado tore through an Oklahoma subdivision in 2019, building inspector David Williams documented something remarkable: “Homes with standing seam metal roofs suffered minimal roof damage despite experiencing winds estimated at 140-150 mph. Neighboring homes with asphalt shingles experienced catastrophic roof failures at much lower wind speeds.”

For maximum wind and impact resistance, pay attention to proper fastener spacing (following manufacturer specs for clip placement), choose deeper standing seam profiles (1.5″ to 2″), ensure strong substrate support, and give special attention to edge securement at eaves, rakes, and ridges to prevent wind from getting under panels.

At DML USA Metal Roofing, our standing seam systems are specifically engineered for the severe weather conditions common throughout Illinois and the Midwest, giving homeowners peace of mind when storms roll in.

Century-Long Performance: Why Copper Still Rules Luxury Builds

For luxury homes designed to stand for generations, copper remains the gold standard of roofing durability. Its extraordinary longevity, natural beauty, and minimal maintenance requirements make it the ultimate choice for those seeking the absolute best roof performance.

Architectural historian Elizabeth Grant shared a fascinating example: “The copper roof on Christ Church in Philadelphia was installed in 1727 and lasted for 275 years before requiring replacement. Even then, much of the original copper was still salvageable. No other roofing material can match that kind of documented performance.”

One of copper’s most distinctive features is its natural patina development—a process that not only creates stunning visual appeal but actually improves durability over time. Metallurgist Dr. James Cooper explained how it works: “Copper begins as a bright penny color, then darkens to a rich brown before eventually developing its characteristic green patina. This patina (copper carbonate) forms a protective layer that prevents further corrosion and can even seal minor scratches and damage.”

This beautiful change typically takes 2-5 years to develop the brown phase, 5-7 years to begin showing green in urban environments, and 10-15 years to fully develop the green patina in rural areas.

Unlike most metal roofing materials, copper can be soldered to create truly watertight seams and details. Master roofer Michael Gonzalez highlighted why this matters: “The ability to solder copper gives it a significant advantage in complex roof designs. We can create details that remain watertight for decades without relying on sealants that eventually fail.”

Copper does have a high coefficient of thermal expansion, meaning it moves significantly with temperature changes. “We use expansion joints and special detailing to allow copper to move freely,” explained copper specialist Thomas Reynolds. “When properly installed with these considerations, a copper roof can last a century or more without issues.”

While copper is indeed the most expensive metal roofing option (typically $20-32 per square foot installed), its extreme longevity makes economic sense for high-end projects. As real estate appraiser Jennifer Williams noted, “When you spread the cost over its service life, copper often costs less per year than many lower-priced alternatives. Plus, it adds significant property value and curb appeal that other materials simply can’t match.”

Factors That Make or Break Metal Roof Durability

You might have the Rolls-Royce of metal roofing materials, but without proper installation and care, even the best roof won’t reach its potential lifespan. Think of it like buying a luxury car but never changing the oil—eventually, problems will surface no matter how premium the initial purchase.

“The most durable metal in the world won’t perform if it’s installed incorrectly,” emphasizes master installer Carlos Rodriguez. “I’ve seen 50-year materials fail in 5 years due to poor installation, and I’ve seen 30-year materials last 50+ years when installed with proper techniques.”

Installation quality truly makes or breaks your roof’s performance. This includes proper fastener placement, correct panel alignment, appropriate underlayment selection, and meticulous attention to flashings and details. Even small mistakes can lead to big problems down the road.

The underlayment acts as your roof’s second line of defense. At DML USA Metal Roofing, we’ve found that high-performance synthetic underlayments significantly outperform traditional materials. These modern underlayments remain watertight for decades, providing crucial backup protection if water ever gets past your metal panels.

Don’t overlook ventilation in your attic space. Without proper airflow, moisture can condense on the underside of your beautiful new metal roof, causing corrosion from the inside out where you can’t even see it happening.

“Inadequate ventilation is one of the most common factors we see in premature metal roof failure,” explains building scientist Mark Johnson. “Moisture condensing on the underside of panels can cause corrosion that no amount of top-side protection can prevent.”

The coating quality on your metal roof dramatically impacts how long it will look good and perform well. The difference between a standard polyester paint and a premium Kynar 500 finish can be 10-20 extra years of service life. Premium finishes resist chalking, fading, and degradation much longer, preserving both appearance and protection.

Your local climate should influence your metal roof choice too. Here in Illinois, we face everything from heavy snow to summer storms, which is why we recommend systems specifically engineered for Midwest weather conditions. A roof that works perfectly in Arizona might struggle in our climate, and vice versa.

Even the most durable metal roofs benefit from regular inspections. Think of it like dental check-ups—catching small issues early prevents bigger problems later. A quick annual look can add decades to your roof’s life by identifying minor repairs before they become major headaches.

Scientific research on zinc usage

Standing Seam vs. Exposed Fastener—Which Lasts Longer?

When it comes to long-term durability, the design of your metal roof system matters almost as much as the material itself. Standing seam and exposed fastener systems represent two fundamentally different approaches, with significant implications for longevity.

Standing seam systems shine when it comes to durability. With hidden fasteners that secure panels without penetrating the metal, you eliminate countless potential leak points. The panels can expand and contract freely with temperature changes, preventing the stress that leads to fastener failure or panel distortion. Those raised seams keep water flowing above the roof plane rather than testing the waterproofing at every opportunity.

“In my 30 years of experience, standing seam systems consistently outlast exposed fastener panels by 15-20 years or more,” shares roofing contractor Mike Williams. “The difference is especially noticeable in climates with extreme temperature variations like we have here in Illinois.”

Exposed fastener roofs tell a different story. Those screws driven directly through the panels might seem secure at first, but they face constant challenges. The rubber gaskets around each screw typically deteriorate within 5-10 years, requiring replacement. As the metal expands and contracts, the holes gradually enlarge, creating potential leak points. With hundreds of penetrations on an average roof, that’s hundreds of opportunities for water to find its way in.

That’s not to say exposed fastener systems don’t have their place. They’re generally more affordable and can work well for structures like detached garages or agricultural buildings. But for your home—where you want maximum durability and minimal maintenance—standing seam is the clear winner.

Real-world performance backs this up. A study of metal roofs in the Midwest found that properly installed standing seam systems had an average service life of 40-60 years before requiring significant maintenance, while exposed fastener systems typically needed major maintenance or replacement after just 20-30 years.

More info about product options

Maintenance Checklist to Maximize a 50-Year+ Lifespan

One of the greatest advantages of a quality metal roof is its low maintenance requirements—but “low maintenance” doesn’t mean “no maintenance.” A little care goes a long way toward ensuring your roof reaches its full potential lifespan.

Annual maintenance doesn’t need to be complicated. Start by removing leaves, branches, and other debris from valleys and gutters. This simple step prevents moisture retention that can lead to corrosion over time. While you’re up there, check for any loose fasteners (especially important on exposed fastener systems) and inspect sealants around penetrations and flashings. Clean your gutters and downspouts to ensure proper drainage, and trim any overhanging branches that might rub against your roof during windy days.

Every five years or so, consider having a professional inspection to catch any developing issues early. A gentle cleaning with mild soap and water can remove built-up contaminants that might eventually damage your roof’s finish. This is also a good time to check your attic ventilation to ensure it’s still functioning properly.

If you live in a region with heavy snowfall like we do in Illinois, consider installing snow guards to prevent dangerous snow slides and reduce stress on seams and fasteners. Proper insulation and ventilation are also crucial for preventing ice dams, which can force water under panels during freeze-thaw cycles.

“The beauty of metal roofing is that it requires minimal maintenance compared to other roofing types,” explains maintenance specialist Sarah Johnson. “A few hours of attention each year can ensure your metal roof reaches its full potential lifespan of 50+ years.”

Common Durability Killers & How to Prevent Them

Even the most durable metal roof can face premature failure if certain critical issues aren’t addressed. Being aware of these common “durability killers” can help you protect your investment.

Galvanic corrosion occurs when dissimilar metals touch in the presence of moisture, creating a tiny electrical current that accelerates corrosion. This is why using the right fasteners and flashings is so important. “I’ve seen copper roofs develop holes in just a few years where steel fasteners were incorrectly used,” notes metallurgist Dr. Robert Chen. “The galvanic reaction between copper and steel is particularly aggressive.” Always use compatible metals throughout your roofing system, and when dissimilar metals must touch, make sure proper isolation materials are installed between them.

Improper flashings and transitions are another major culprit in premature roof failure. These critical junctions—where your roof meets walls, chimneys, or other roof planes—require meticulous attention to detail. Proper overlaps, appropriate sealants, and adherence to manufacturer-approved designs are essential for long-term performance.

Ponding water is the enemy of any roof, even metal ones. While metal resists water damage better than most materials, standing water can eventually compromise even the best finishes. Ensure your roof has proper slope (minimum 1:12 for most metal roof systems), address any areas where debris might collect, and correct any structural issues that might cause deflection.

Poor ventilation might be the most overlooked durability killer. “In my forensic work investigating roof failures, inadequate ventilation is implicated in nearly 80% of premature metal roof corrosion cases,” reports building scientist Joseph Lstiburek. “It’s the silent killer of otherwise durable metal roofs.” Proper intake and exhaust ventilation prevents condensation on the underside of panels, avoiding corrosion from the inside out.

Finally, be cautious about incompatible materials coming into contact with your metal roof. Certain sealants, accessories, or adjacent materials can cause chemical reactions that damage metal roofing. Use only manufacturer-approved products, avoid direct contact with pressure-treated lumber without proper isolation, and be careful about runoff from higher roofs made of different materials.

By addressing these potential issues proactively, you’ll help ensure your what is the most durable metal roof investment delivers decades of reliable protection for your home.

Frequently Asked Questions About What Is the Most Durable Metal Roof

What is the most durable metal roof for extreme weather?

When Mother Nature decides to show her strength, not all metal roofs respond the same way. The most durable metal roof for your home really depends on what kind of weather challenges you face in your region.

If you live along the coast where hurricanes threaten, standing seam systems shine brightest. Aluminum stands out in coastal hurricane zones because it naturally resists salt corrosion – a silent destroyer of many roofing materials. For inland areas that still see hurricane-force winds, steel standing seam systems rated for 140+ mph winds provide excellent protection.

“I’ll never forget what we found after Hurricane Michael hit Florida in 2018,” shares FEMA building scientist Robert Johnson. “While most roofing systems failed completely, properly installed standing seam metal roofs were still protecting homes – even after Category 5 winds.”

For homeowners in Hail Alley across the Midwest, steel standing seam systems with UL 2218 Class 4 impact ratings offer the best defense. These systems have a remarkable ability to flex slightly with impact, absorbing energy without puncturing – unlike rigid roofing materials that crack under pressure.

If heavy snow is your concern, standing seam copper or steel systems excel. Their smooth surface naturally sheds snow instead of allowing dangerous accumulation, while strong seams support heavy loads when needed. Many homeowners in snowy regions add snow retention systems for controlled snow management.

For homes baking under intense sun, look to aluminum or steel with highly reflective PVDF finishes. The best options carry ENERGY STAR ratings with solar reflectance values above 0.65 – meaning they reflect most of the sun’s heat away from your home rather than absorbing it.

Does the most durable metal roof require special maintenance?

Here’s some good news – the most durable metal roof options actually require less maintenance than standard roofing materials. That said, a little attention goes a long way toward maximizing their already impressive lifespan.

Premium copper and zinc roofs are practically maintenance-free. Beyond occasionally clearing debris and checking for any mechanical damage (like from fallen branches), these metals largely take care of themselves. Their natural patinas aren’t just beautiful – they’re functional protection that improves with age.

“My clients with copper roofs are always surprised,” says restoration specialist Thomas Reynolds with a smile. “They expect complicated maintenance routines, but in 40 years, they might only need attention to flashings and connection points. The copper itself just keeps going strong decade after decade.”

Aluminum and steel systems need slightly more attention, but still far less than asphalt or wood alternatives. An annual walk-around to check for loose fasteners (especially important with exposed fastener systems), periodic cleaning to remove debris, and checking sealants at penetrations every 5-7 years will keep these systems performing beautifully.

The quality of the finish makes a significant difference in maintenance needs. As Sarah Johnson, a maintenance specialist, explains: “A premium Kynar 500 finish might look practically new after 30 years with minimal care, while standard polyester finishes often show significant fading and chalking after just 10-15 years.”

How does cost compare to lifespan on the most durable metal roof?

The sticker shock of premium metal roofing can cause some homeowners to hesitate, but looking at the complete picture often reveals a different story. When you consider the full lifecycle, the most durable metal roof options frequently become the most economical choice.

Consider this real-world example for a typical 2,000 square foot home in Illinois:

While asphalt shingles might seem affordable at around $10,000 initially, you’ll replace them 5-6 times over a century, bringing your total to $50,000-$60,000 (and that’s not accounting for inflation).

A quality Galvalume steel roof might cost $20,000 upfront but only needs replacement once or twice in the same timeframe, totaling $20,000-$40,000.

A copper roof at $50,000 could very well outlast your home itself, potentially never needing replacement – making its century-long cost exactly what you paid upfront.

“These calculations actually understate the value,” notes financial analyst Robert Thompson. “They don’t account for the hassle of multiple replacements, disposal costs, or inflation – all of which make premium metal roofing even more attractive over time.”

Beyond simple longevity, premium metal roofs deliver additional value through energy savings (often reducing cooling costs by 10-25%), insurance discounts (many companies offer 5-35% premium reductions for impact-resistant roofing), and improved resale value (metal roofing recovers approximately 61% of its cost when you sell – higher than many other home improvements).

Many homeowners are also pleasantly surprised to find tax benefits. Energy-efficient metal roofing may qualify for federal tax credits and local incentives that further sweeten the deal.

Here at DML USA Metal Roofing, we help Illinois homeowners find that sweet spot – the metal roofing system that balances initial investment with long-term durability to deliver the best value for your specific situation and budget. We believe in honest conversations about lifetime costs, not just focusing on the initial price tag.

Conclusion

When it comes to answering the question of what is the most durable metal roof, the evidence points to a clear winner: premium metals like copper, zinc, and stainless steel truly stand the test of time, with lifespans measured in generations rather than decades. That said, high-quality steel and aluminum systems offer excellent durability at more budget-friendly prices, making them smart choices for most homeowners looking for that sweet spot between performance and cost.

Through our conversations with experts and decades of experience in the field, we’ve finded some valuable insights worth sharing:

First, while your choice of metal certainly matters, it’s not the whole story. Even the finest copper roof won’t perform well if it’s poorly installed or if your attic isn’t properly ventilated. The craftsmanship behind your roof installation can be just as important as the material itself.

Second, the design of your roofing system makes a huge difference. Standing seam systems consistently outlast exposed fastener designs thanks to their hidden fasteners, raised seams, and ability to expand and contract with temperature changes. For homes you plan to stay in long-term, the standing seam design is worth the investment.

Third, don’t underestimate the importance of a quality finish. The difference between a standard polyester coating and a premium Kynar 500 finish isn’t just about looks – it can add 10-20 years to your roof’s lifespan. When you spread that cost over decades of service, the premium option often becomes the more economical choice.

Fourth, your local climate should guide your selection. The “most durable” choice varies depending on where you live – aluminum shines in coastal areas where salt corrosion is a concern, while steel offers superior protection in regions prone to hailstorms and severe weather.

Finally, when you look at the big picture of lifetime costs, maintenance needs, and energy savings, higher-quality metal roofing systems typically deliver better long-term value despite their higher initial price tags. Factor in fewer replacements, lower cooling costs, potential insurance discounts, and improved resale value, and premium metal roofs often pay for themselves over time.

Here at DML USA Metal Roofing in Illinois, we’re passionate about helping homeowners make smart, informed decisions about metal roofing. Our manufacturing facilities in Northlake and Chicago produce high-quality, American-made metal roofing systems specifically engineered for the challenging Midwest climate.

Whether you’re building your dream home or replacing an aging roof, choosing a durable metal roof means making a decision your future self will thank you for. With proper installation and minimal maintenance, today’s premium metal roofing systems truly can be the last roof your home will ever need.

More info about our metal roofing products